Eucy,Could the problem be that EPS is too soft through the thickness to hit the HF - have you compared it to XPS?

Eucy

The problem is EPS seems not having the same performances for all of us (may be true for other material?) and we (or at least I) can't say why... what is the key parameter? Not the same EPS? Other reason (see just before the discussion about the exciters).

Christian

When it will be possible (for some constraints I am a bit far for all my DML stuff for now and this for some weeks), I will coat the 7mm sample I have. As it reaches about 8k, it should proff the benefit of coating. The behavior of the second panel shown in #5687 (600x800mm 15kg/m3 20mm EPS coated) is another story?Eucy.

I have posted many plots over the years showing the good hf response that EPS can have if the exciter is capable.

Even my very soft EPS low grade panel , when coated in pva reaches 20k.

I took measurements of the uncoated panel as well for comparisons.

I think the uncoated panel struggled to reach 8k without the coating ?

If you can get the EPS panel to reach about 10k with its usual 10k peak and dip afterwards , there are easy ways to sort this out.

Steve.

Christian

This just leads me to think about other possibility about HF performance : is there a risk of difference by the measurement devices? Your favorite tool Steve is the RTA of the Behringer DEQ2496. I add a look to the manual. The RTA is a 61 bands but I have found no information about the bandwidth of each band. Is 1/6, 1/3 of octaves?just found the post for the low grade and the 70grade uncoated panels, things are easily lost in this forum !

Steve.

I don't see the same roll-off when measuring my regular speakers, so I'm quite sure it is not the measurement device in my case.

Regarding the DEQ2496, with the audible range being around 10 octaves, 61 bands must be 1/6 oct. I'm not familiar with the unit, and I assume the FR display is always Z-weighted?

Regarding the DEQ2496, with the audible range being around 10 octaves, 61 bands must be 1/6 oct. I'm not familiar with the unit, and I assume the FR display is always Z-weighted?

It's all good fun.Hi Steve

The new sample boards are now awaiting courier pickup.

I hope they are able to deliver a good account for themselves.

let's hope for the best.

Steve.

Hi Steve,

To have more criteria for the exciter choice would help but up to now I have no real way... My basic criterias are high BL, low mass, low inductance. Previous posts shown the role of the inductance. My tests around the voice coil mass haven't shown it is very critical.

When I come back to the comparison of specifications :

The TEAX has a lower mass (1g vs 1.6g) but no evidence it is an advantage

- The TEAX25C10-8/HS you use (see post #3433)

- The Dayton Audio DAEX25FHE4 commonly used

Their inductances are similar at 0.1mH... but the TEAX is 8Ohms which means the cut off frequency is higher. This might be a good point.

The problem is the TEAX or HIAX seems not easy to find. Do you know some suppliers or equivalences?

Extract of the specifications

View attachment 1052735

View attachment 1052737

FWIW, I have tried only 2 Dayton exciters, DAEX25SHF-4 (expensive) , and the thruster DAEX32EP-4 (just over half the price of the 25SHF-4) (apart from a bass shaker which was a dismal failure).

The 25SHF-4 is a quality piece of kit - solid magnet casting-heavy, and easily matches the output of the thruster at half the power input. It also has a smaller piston and (maybe therefore ?) better HF performance. The thruster seems a cheap bit of stuff compared to the 25SHF-4.

The only other one I think is worth trying is the DAEX30HESF-4 - again expensive here in Aus.

Cheers

Eucy

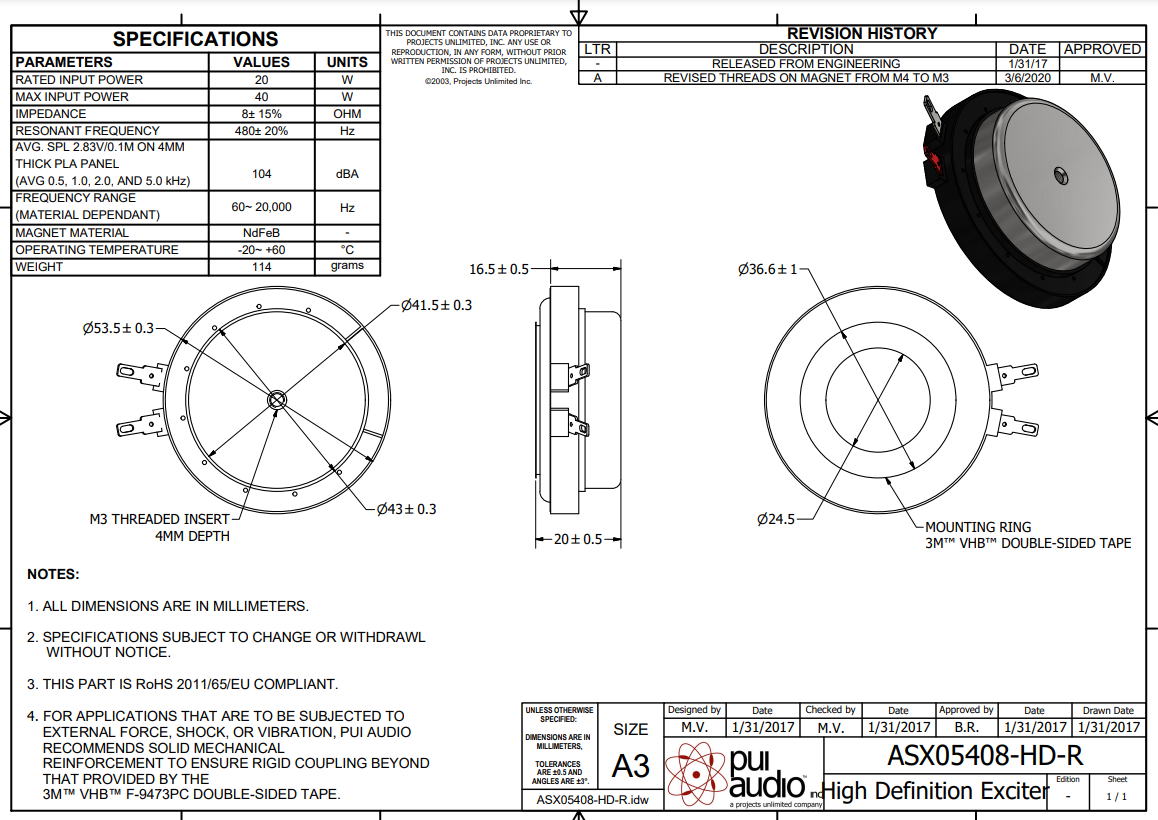

One of the reasons I started using the following PUI exciter is they provide some worthwhile specifications including frequency range.

Thanks, Dave

Thanks, Dave

I did look at that exciter but was very disappointed with the spec sheet since they basically only publish nominal impedance, resonant frequency and frequency range. The Daytons are specified as having a range to 20k as well according to soundimports. Doesn't say anything though without specifying at what deviation. Even my really high impedance 50w exciters, that had very little HF reproduction, did have a range up to 20k.One of the reasons I started using the following PUI exciter is they provide some worthwhile specifications including frequency range.

Thanks, Dave

View attachment 1052925

Hello DaveOne of the reasons I started using the following PUI exciter is they provide some worthwhile specifications including frequency range.

Thanks, Dave

View attachment 1052925

Do you know what is "PLA" (PolyLactic Acid?) as material in the efficency specification?

Christian

Interesting. PLA is the most commonly used plastic for 3D printing. It is a plastic made from starch, relatively brittle and with a low glass transition temperature. You can also get plates like this: https://www.amazon.com/Tamiya-70122-Plastic-Panel-Pieces-White/dp/B001Q150W0Hello Dave

Do you know what is "PLA" (PolyLactic Acid?) as material in the efficency specification?

Christian

Not sure why they include that data, since PLA is not that efficient to start with, and from what I have seen very uncommon choice. Measurement is at 0.1m, so translating to typical 1m measurement it would be 84dB efficient.

Thank you LeobInteresting. PLA is the most commonly used plastic for 3D printing. It is a plastic made from starch, relatively brittle and with a low glass transition temperature. You can also get plates like this: https://www.amazon.com/Tamiya-70122-Plastic-Panel-Pieces-White/dp/B001Q150W0

Not sure why they include that data, since PLA is not that efficient to start with, and from what I have seen very uncommon choice. Measurement is at 0.1m, so translating to typical 1m measurement it would be 84dB efficient.

PLA is about 1250kg/m3 density so 5kg/m² in 4mm thickness so abit higher than acrilyc. That's right : not good for efficiency. Strange choice.

Hi,

Finally got a couple of stretched canvas frames of size 16 x 12 inch, as in attachment.. 🙂 ..

Please help in selecting the exciter , so far thinking to order one of the below exciters :

Dayton Audio DAEX25Q-4 (available locally here)

https://diyaudiocart.com/Dayton-Audio-DAEX25Q-4-Quad-Feet-25mm-Exciter-20W-4-Ohm

Dayton Audio DAEX25FHE-4 (available in below site, need to import)

https://www.soundimports.eu/en/dayton-audio-daex25fhe-4.html

Finally got a couple of stretched canvas frames of size 16 x 12 inch, as in attachment.. 🙂 ..

Please help in selecting the exciter , so far thinking to order one of the below exciters :

Dayton Audio DAEX25Q-4 (available locally here)

https://diyaudiocart.com/Dayton-Audio-DAEX25Q-4-Quad-Feet-25mm-Exciter-20W-4-Ohm

Dayton Audio DAEX25FHE-4 (available in below site, need to import)

https://www.soundimports.eu/en/dayton-audio-daex25fhe-4.html

Attachments

The equipment and material to do vacuum bagging should all be here tomorrow. Plan is to follow this video posted earlier:

I got some 3mm nomex and 80g glass to practice with, and some 64g spread tow carbon for the final plates...unless I think the glass performs better.

One thing I'm unsure about is the direction of the honeycomb in relation to the dimensions of the panel. If the goal is to distribute the modes, is it best to have the strong direction on the short side?

One thing I'm unsure about is the direction of the honeycomb in relation to the dimensions of the panel. If the goal is to distribute the modes, is it best to have the strong direction on the short side?

JohnnoG.

Your panels arrived today .

I will just take the taped on exciter , off of your other panel , and see how it sounds , and measures up compared those panels?

The flutes on these panel are square compared to the thicker panels.

Steve.

Your panels arrived today .

I will just take the taped on exciter , off of your other panel , and see how it sounds , and measures up compared those panels?

The flutes on these panel are square compared to the thicker panels.

Steve.

Tortuous wording for anisotropic stiffeningAnother way to increase panel stiffness:https://patents.google.com/patent/US5072642A/en

I have no experience with either of these but I have read of issues with the frog-leg types so I'd stick with the second one as a starting point. Be aware though that there are higher quality units available (at correspondingly higher prices).Hi,

Finally got a couple of stretched canvas frames of size 16 x 12 inch, as in attachment.. 🙂 ..

Please help in selecting the exciter , so far thinking to order one of the below exciters :

Dayton Audio DAEX25Q-4 (available locally here)

https://diyaudiocart.com/Dayton-Audio-DAEX25Q-4-Quad-Feet-25mm-Exciter-20W-4-Ohm

Dayton Audio DAEX25FHE-4 (available in below site, need to import)

https://www.soundimports.eu/en/dayton-audio-daex25fhe-4.html

Best Wishes

Eucy

I wouldn't - but I'm a believer in trying to balance anisotropy in rectangular panels 👍 🙂- others may not be (and that's fine)One thing I'm unsure about is the direction of the honeycomb in relation to the dimensions of the panel. If the goal is to distribute the modes, is it best to have the strong direction on the short side?

90%+ of the bending stiffness will come from the skins anyway - so I would think the nomex direction won't have any measurable effect. The nomex really only serves to separate the skins - panel stiffness is a function of the distance of the skins from the neutral axis of the composite.

A structural analogy is the 'H' steel beam in which the (thinner) web portion serves to provide shear strength and to separate the (thicker) flanges which provide the bulk of the bending stiffness.

Eucy

Thanks Eucy, that makes sense structurally I guess, but figured it made less sense acoustically. But you are probably right it will not matter really.I wouldn't - but I'm a believer in trying to balance anisotropy in rectangular panels 👍 🙂- others may not be (and that's fine)

90%+ of the bending stiffness will come from the skins anyway - so I would think the nomex direction won't have any measurable effect. The nomex really only serves to separate the skins - panel stiffness is a function of the distance of the skins from the neutral axis of the composite.

A structural analogy is the 'H' steel beam in which the (thinner) web portion serves to provide shear strength and to separate the (thicker) flanges which provide the bulk of the bending stiffness.

Eucy

johnnoG

the sticky tape did not stick too well and the exciter fell off after about an hour.

so i have cleaned the surface with alcohol and made a quick recording in case it falls off again.

this panel is more efficient than the heavier panel , about 3db or more ?

there is also a roll off above 9k but only 7db or so by 20k.

this could just be the sticky tape as the heavier panel with glued on exciter has a rising response above 9k of about 5db ?

the new panel is on the right and is still slightly louder so you can hear it more , i hope.

steve.

the sticky tape did not stick too well and the exciter fell off after about an hour.

so i have cleaned the surface with alcohol and made a quick recording in case it falls off again.

this panel is more efficient than the heavier panel , about 3db or more ?

there is also a roll off above 9k but only 7db or so by 20k.

this could just be the sticky tape as the heavier panel with glued on exciter has a rising response above 9k of about 5db ?

the new panel is on the right and is still slightly louder so you can hear it more , i hope.

steve.

Attachments

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker

![IMG-20220428-WA0010[1].jpg](/community/data/attachments/961/961500-bcae790fb67648b83483686d3383c138.jpg?hash=vK55D7Z2SL)

![IMG-20220428-WA0013[1].jpg](/community/data/attachments/961/961501-1e4fbc77b11deb631c0958ccf0c25062.jpg?hash=Hk-8d7Ed62)