Yes Saturday and Sunday.Anyone going to the High End Munich 2022, May 19 to 22?

https://www.highendsociety.de/high-end-44.html

Howie,Hi John!

I think we only used 316 SS Swagelock fittings, etc. We used their dielectric separators where things were hard-piped: https://products.swagelok.com/en/fittings/dielectric-fittings/c/108?clp=true

The only way to have a system with so many liquid connections leak-free was to use their system with torque gauges and train techs to use them.

Good luck with this issue; we had excellent service with our plasma target cathode cold-plates and anode/magnet coolers with the full suite of chiller additives. On the other hand our 11 M ohm system was entirely intolerant of any metal fittings. The 11 M ohm system was of course a continuously polishing loop through mixed DI beds because a certain percentage of water wants to become H and OH so damn badly!! The loop extended all the way to the tips of the spray nozzles in order to ensure ion-free water, even at the first nozzle opening. Optical disc manufacturing was a really tech-intensive way to make dirt-cheap disposable consumer trash....I mean high-quality CDs and DVDs.

I going to bed, GN!

Howie

Thank you for your sharing of knowledge.

I am in awe..

John

Also, I'm curious what conductivity the water takes when it reaches (passive) equilibrium. The more conductive the water, the more those fields can spread, which is a gift that keeps on giving. Probably impossible at this juncture and an absurd amount of cost/waste -- no way that you can passivate the surfaces or get some plating inside? Otherwise, I'm at a loss. Also, I'm trusting Howie here, as my issues lie with other forms of electrochemical attack than pure Cu chiller pipes in highly pure water (at least initially).However, the DI does attack the copper, so the copper ions in solution will aggressively bond to the oxygen being generated at the positive potential fittings (anodes) hence the quick buildup of CuO. I also worry that the more copper we deposit, the more gets pulled from the magnet coils. Eventually, we may need to changeover to 30 thousand gallons of prestone antifreeze to close all the pinholes.

jn

It's been a minute since I was a henchman in our university fab, but we put all kinds of additives in the water chiller loops. Sorry I'm not of help.

All you Big Brains have missed the point: you've got your negative feedback coupled in with your push-pull input-output. For more details:

All good fortune,

Chris

All good fortune,

Chris

It's easy to forget what a darned good solvent pure water is! Of course us mortals never get close to anything that dangerous...

Regarding leaching in deionized chilled water systems, we used water cooled tubes @ about 10kv in cyclotron oscillators and HV supplies. Magnesium 'sacrificial anodes' were attached to tube anodes to minimize anode erosion. The magnesium rods were treated as consumables.

In other chilled water applications where high resistivity was not required (say, electron linacs), additives were used to inhibit both corrosion and mold growth.

In other chilled water applications where high resistivity was not required (say, electron linacs), additives were used to inhibit both corrosion and mold growth.

As we have a chemistry department, I decided to email the director and explain the issue and ask for assistance.

Tomorrow I meet the head of one organization. Twill be interesting, he uses words I've never heard before..

Hey, if ya gonna ask for help, might as well be one of the best in the world...

I can't retire, I'm having too much fun. Well, ok, I also have to pay for my toys...

jn

Tomorrow I meet the head of one organization. Twill be interesting, he uses words I've never heard before..

Hey, if ya gonna ask for help, might as well be one of the best in the world...

I can't retire, I'm having too much fun. Well, ok, I also have to pay for my toys...

jn

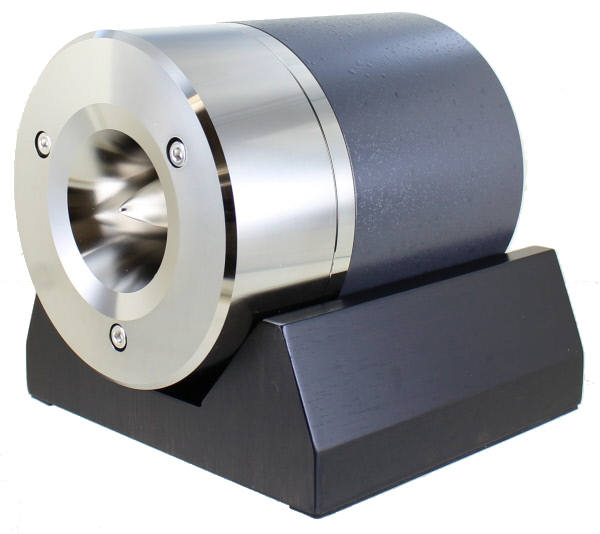

Curious audio component of the day https://eng.hifirose.com/RA180

It's a 4 channel integrated with a built in cross-over for biamping or running as 2 channel bridged and a curious mix of 70s design, bit of Nagra and steampunk with the volume control. I have to admire their approach but wonder who on earth it is aimed at...

It's a 4 channel integrated with a built in cross-over for biamping or running as 2 channel bridged and a curious mix of 70s design, bit of Nagra and steampunk with the volume control. I have to admire their approach but wonder who on earth it is aimed at...

I like the Nagraesque design, and the specs look current Class D, but I am disgusted by their failure to use anti-backlash gears in their steam-punk volume control excsss....so disappointing!!! (lolol)Curious audio component of the day https://eng.hifirose.com/RA180

It's a 4 channel integrated with a built in cross-over for biamping or running as 2 channel bridged and a curious mix of 70s design, bit of Nagra and steampunk with the volume control. I have to admire their approach but wonder who on earth it is aimed at...

Cheers!

Howie

Well, it is good that they named the intermediate gear "gallium nitride". I usually call my intermediate gear "Bob".

From the waveforms presented, they don't know how to control high speed circuit loops. <<actual engineering speak<<

And, I look forward to the day when my amp can handle "super twitters".

jn

From the waveforms presented, they don't know how to control high speed circuit loops. <<actual engineering speak<<

And, I look forward to the day when my amp can handle "super twitters".

jn

I take it you are looking forward to the new ownership making twitter into super twitter! How prescient of you.

Isn't "super twitter" Elon Musk now? I always thought he was something of a twit. He calls himself "Technoking".

Curious indeed, super twitterable for sure.Curious audio component of the day

- Home

- Member Areas

- The Lounge

- The Black Hole......