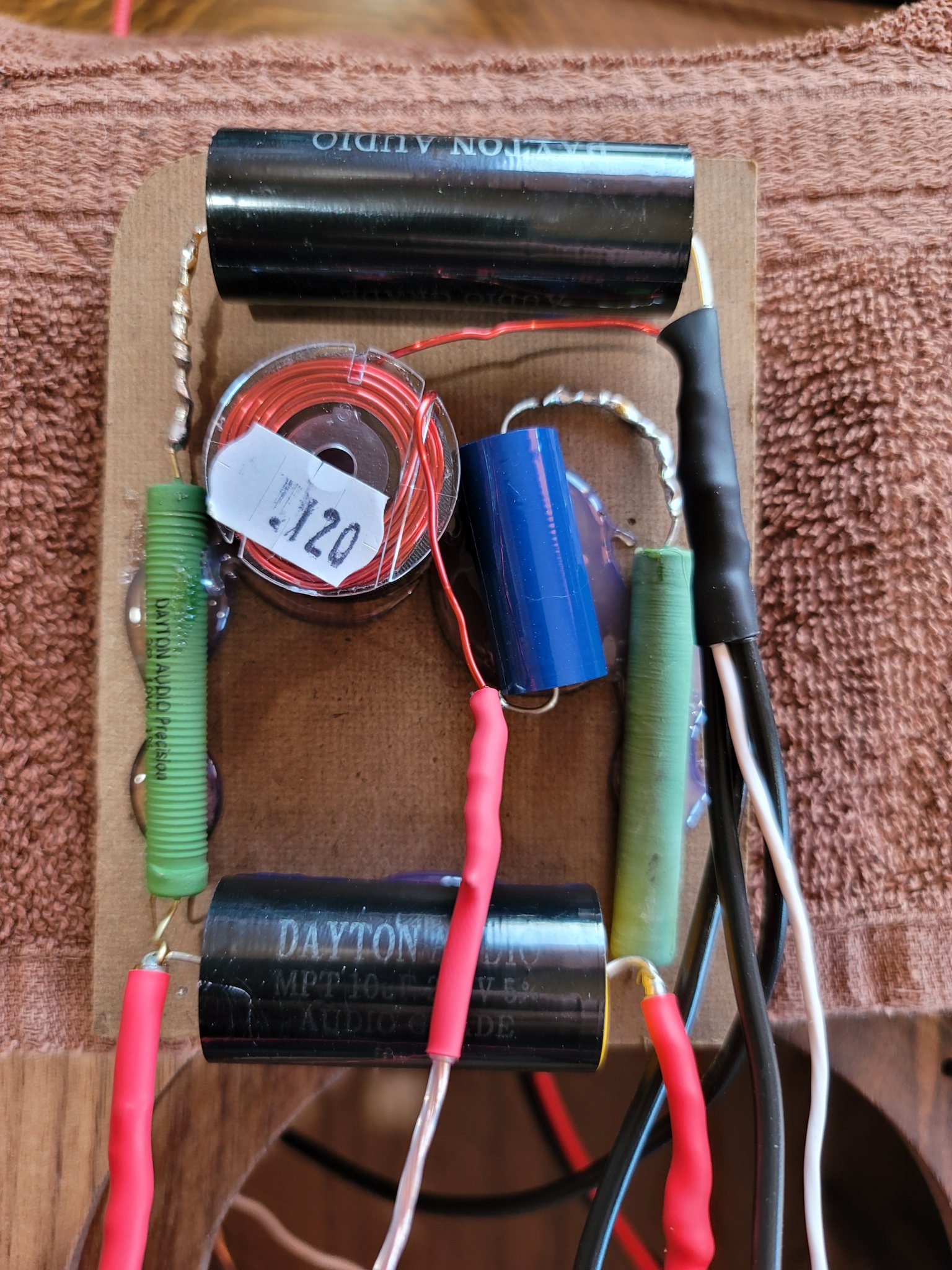

My crossover is 600hz lowpass for the woofer, 600hz highpass for the fullrange, both 1st order. The backfiring tweeter is crossed around 6600hz highpass 3rd order.I can to make a crossover

Is possible to have a frequency cross?

Thanks

Im not sure about this carpenters? since speaker consist cabinet, driver, crossover, ... I see some project with cardboard cabinet but if U educate yourself a little bit more, u can find that is one favorite HI FI company make cabinet and after that make drivers to adapt to this cabinet (to help U, at first company make just drivers, now U can not buy drivers, only complete speakers)

Ill attach scheme , pict and impedance dia ...

Last year at the Munich Fair I was impressed with boenicke w5, but unfortunately price is bigger than my limit , especially SE version

Since we have design studio and 2 CNC machine (for other purpose) I tried to do it something similar, but way is more than complicate since need to make holes on 3 different side s

No meter, if not counting our time, material, drivers, crossover and rest is almost 20 percent of price of W5SE

After I test it, sound is more than awesome

Here is couple pict from production process

BTW my workmates is also make pair for him, and we order material for one pair for our office 🙂

Nice work!Last year at the Munich Fair I was impressed with boenicke w5, but unfortunately price is bigger than my limit , especially SE version

Since we have design studio and 2 CNC machine (for other purpose) I tried to do it something similar, but way is more than complicate since need to make holes on 3 different side s

No meter, if not counting our time, material, drivers, crossover and rest is almost 20 percent of price of W5SE

After I test it, sound is more than awesome

Here is couple pict from production process

BTW my workmates is also make pair for him, and we order material for one pair for our office 🙂

Would like to do the same build. I'm an audiophile/woodworker. Do you have pattern or cad file? If so, can you share or send to me.

I would also be interested in the xovers, drivers, wiring, and damping material. How it was assembled. The full build.

Thx

Im not sure about this carpenters? since speaker consist cabinet, driver, crossover, ... I see some project with cardboard cabinet but if U educate yourself a little bit more, u can find that is one favorite HI FI company make cabinet and after that make drivers to adapt to this cabinet (to help U, at first company make just drivers, now U can not buy drivers, only complete speakers)

Ill attach scheme , pict and impedance dia ...

Last year at the Munich Fair I was impressed with boenicke w5, but unfortunately price is bigger than my limit , especially SE version

Since we have design studio and 2 CNC machine (for other purpose) I tried to do it something similar, but way is more than complicate since need to make holes on 3 different side s

No meter, if not counting our time, material, drivers, crossover and rest is almost 20 percent of price of W5SE

After I test it, sound is more than awesome

Here is couple pict from production process

BTW my workmates is also make pair for him, and we order material for one pair for our office🙂

Nice work!Last year at the Munich Fair I was impressed with boenicke w5, but unfortunately price is bigger than my limit , especially SE version

Since we have design studio and 2 CNC machine (for other purpose) I tried to do it something similar, but way is more than complicate since need to make holes on 3 different side s

No meter, if not counting our time, material, drivers, crossover and rest is almost 20 percent of price of W5SE

After I test it, sound is more than awesome

Here is couple pict from production process

BTW my workmates is also make pair for him, and we order material for one pair for our office🙂

Would like to do the same build. I'm an audiophile/woodworker. Do you have pattern or cad file? If so, can you share or send to me.

I would also be interested in the xovers, drivers, wiring, and damping material. How it was assembled. The full build

Thx

If anyone is interested, I’ve made 3D models of these in Fusion360. I can share the stl or fusion files. I’ve printed them in 8 parts and I’m just waiting for the crossover parts to arrive.

If anyone is interested, I’ve made 3D models of these in Fusion360. I can share the stl or fusion files. I’ve printed them in 8 parts and I’m just waiting for the crossover parts to arrive.

Interested in both the fusion360 and .stl file. Please attach...THX!If anyone is interested, I’ve made 3D models of these in Fusion360. I can share the stl or fusion files. I’ve printed them in 8 parts and I’m just waiting for the crossover parts to arrive.

👍 Thx....I also have 2 pair I'd like to use to DIY build some W5's with. Need template or CAD files. Could even work with a 2D file. Any suggestions?

They look great! Did you make then yourself? By hand/router template or CNC? If outsourced, what did it cost?

What is your process to clone the boxes? Do you have all the driver, xover info for the W8,s?No. But its very easy to reverse engineer it. There are enough pictures available on the internet.

The bigger variant, the W8 are also rather easy to DIY and are even better. Here a test cut :

What I dont get is that the resistor and the cap in line with the Fountek (2 ohm , 12 uf) - according to the theory - dont have any influence on the sound? I never ever saw something like this.

Is the fe86 or 87 a possible substitut?But did you recived it? Because they don't have it also, couple of days after the order they sent me a message and cancel the order...

Bandpass for the Fountek fullranger? I think according to the description from boenicke it is not limited in hights, runs open to the end. It has only one high pass Filter? (10uf)?Hello Stramer,

Not sure if I can answer your question directly here...............

I basically use the crossover schematic shared by Etonis on post #6 of this thread. The components I use are

For the FE85's band pass:

Obbligato gold premium 10uF

Panasonic EZP-E 12uF

Mills MRA12 2.2ohm

For the tweeter high pass:

Obbligato gold premium 2.2uF

Mills MRA12 10ohm

Mundorf foil inductor 0.12uH

No crossover for the woofer...

Do note that I lack the technical training so I am not able to tell you what are the crossover frequencies.

I first tried listen to them without crossover and without the rear tweeter, the highs were just "incomplete". Then I install the tweeter with the high pass filter, but without band pass for the FE85, the highs were ok but somehow I just cannot listen to them for too long before getting a headache :-(

Finally I connect the band pass for FE85s and they sounded so much more pleasant to listen to.

Unfortunately I believe I have problems with my room acoustics, and that my refrigerator in my small little apartment is humming at around 65~80Hz, the low frequency somehow resonated too much and was rather unbearable. So I finally sealed the tunnel port and now they are lovely to listen to, the bass are very sufficient and full in my apartment and they are fast and punchy too.

Hope the above helps a little.

Have a safe Christmas.

Why not. I have a box of 4 FE88ex ready to ship from before the big price increase.Is the fe86 or 87 a possible substitut?

dave

Are you going to make your w5 with FE88ex?Why not. I have a box of 4 FE88ex ready to ship from before the big price increase.

dave

I built a pair of Boenicke W5 clones out of walnut. I downloaded the fusion 360 file from this thread, then made my 2D drawings in Autocad to actually import into Vectric Aspire to do the toolpaths. I used the Tang Band woofer with the crossover mentioned on the first page. I machined the back aluminum binding post/tweeter plates on my CNC as well.

- Home

- Loudspeakers

- Multi-Way

- Boenicke W5 clone