I did come across that video when looking in to how to make wet-bag layups, and my thoughts was that since the glass is very thin it might still be good, but carbon does beat glass when it comes to stiffness compared to weight. So it is probably a bit heavier than if you would do the same with a very thin carbon weave?If you watch his testing it's fairly flexible, but with extremely high stiffness to weight.

It would be cool to put some lighting effects behind it.

My hopes for it would be to get performance close to carbon sandwich, but at lower cost.

Interesting. Fig 1C seems identical to the suspension used in the animation in the video, and clearly shows exciter placement.Tectonic patent

Have a look to this patent : WO2016118341A1 Audio transducer stabilization system and method

Not read it completly but seems showing details of the Tectonic design.

Carbon is less stretchy than e-glass so you would get stiffer but also less durable. This panel is CRAZY light so I suspect the bit of flex might not be a detriment. You could do the same technique with carbon but carbon that light is hard to come by.I did come across that video when looking in to how to make wet-bag layups, and my thoughts was that since the glass is very thin it might still be good, but carbon does beat glass when it comes to stiffness compared to weight. So it is probably a bit heavier than if you would do the same with a very thin carbon weave?

My hopes for it would be to get performance close to carbon sandwich, but at lower cost.

Christian.

I think you must have ment this patent ?

https://patents.google.com/patent/US9660596B2/en?inventor=Timothy+Whitwell

Steve.

I think you must have ment this patent ?

https://patents.google.com/patent/US9660596B2/en?inventor=Timothy+Whitwell

Steve.

Going quickly through them, they seem having the same content.Christian.

I think you must have ment this patent ?

https://patents.google.com/patent/US9660596B2/en?inventor=Timothy+Whitwell

Steve.

Carbon should be lighter than glass, and the suppliers I have been looking at do have light carbon weave. Carbix.se has these figures for the weaves:Carbon is less stretchy than e-glass so you would get stiffer but also less durable. This panel is CRAZY light so I suspect the bit of flex might not be a detriment. You could do the same technique with carbon but carbon that light is hard to come by.

64g/m2 carbon:

Resin consumption: 46 g/m², laminate thickness: 0.064 mm, laminate weight: 110 g/m²

80g/m² glass:

Resin consumption: 63 g / m², laminate thickness: 0.088 mm, laminate weight: 143 g / m²

They also have 36g/m² aramid weave:

Resin consumption: 51 g/m², laminate thickness: 0,071 mm, laminate weight: 87 g/m²

Christian.

Sorry, but when I go into your link ,there is no text or figs ?

Very strange ?

Steve.

Sorry, but when I go into your link ,there is no text or figs ?

Very strange ?

Steve.

Narenaud.

In this later NXT patent, in fig 8 you can see basically the same design , but more complicated.

this has a lot in common with an ABR unit.

What I like about this idea is that the whole surface of the panel is being driven by the air pressure, and if mounted correctly ,the surface moves as one.

Although you can rigidly mount the edges if wanted.

It just intrigues me, and I've always wondered what it would sound like ?

Steve.

In this later NXT patent, in fig 8 you can see basically the same design , but more complicated.

this has a lot in common with an ABR unit.

What I like about this idea is that the whole surface of the panel is being driven by the air pressure, and if mounted correctly ,the surface moves as one.

Although you can rigidly mount the edges if wanted.

It just intrigues me, and I've always wondered what it would sound like ?

Steve.

The art panel has now got it's exciter attached.

The panel feels quite stiff , not a lot of movement, we will have to see if my exciter is powerful enough to drive this ?

I will be very interested in the response below 300hz.

I don't expect any change in the response in the HF region.

Would a eps of xps panel be better for this, maybe even with epoxy skin ?

Similar to a KEF B139 ?

For bass duties obviously.

Steve.

The panel feels quite stiff , not a lot of movement, we will have to see if my exciter is powerful enough to drive this ?

I will be very interested in the response below 300hz.

I don't expect any change in the response in the HF region.

Would a eps of xps panel be better for this, maybe even with epoxy skin ?

Similar to a KEF B139 ?

For bass duties obviously.

Steve.

Attachments

Christian.

I had about four apps on my phone ,but mostly I used this one, as it was easy to move recording to my computer using Wi-Fi direct, for converting.

I had the free versions , I think this is now pay for only ?

https://play.google.com/store/apps/details?id=com.hiqrecorder.full&gl=us

one of the others was Recforge 2 .

Can't remember the names of the other ones, you can turn off the AVC,

Steve.

I had about four apps on my phone ,but mostly I used this one, as it was easy to move recording to my computer using Wi-Fi direct, for converting.

I had the free versions , I think this is now pay for only ?

https://play.google.com/store/apps/details?id=com.hiqrecorder.full&gl=us

one of the others was Recforge 2 .

Can't remember the names of the other ones, you can turn off the AVC,

Steve.

Well , I couldn't wait any longer ,so hooked up the art panel next to my eps panel.

I did my usual adjustment to the channel levels, but something was wrong ,the panel was too loud.

It was only a few db lower than the eps ?

So I put up my art panel with the ply on the front side and took down the eps panel.

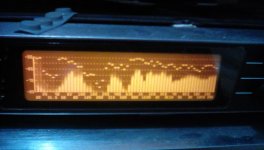

It is still too loud , the photo shows this.

The upper dotted line is the new art panel the lower thick line is the actual real time response .

The new panel is between 5db to 10db louder ?

I'm going to have to swop them over to make sure that nothing has gone wrong with the amp ?

The responses seem similar but the larger ply panel handles the bass better, as I suspected.

Before I say anymore I'd better try and figure this out ?

Steve.

I did my usual adjustment to the channel levels, but something was wrong ,the panel was too loud.

It was only a few db lower than the eps ?

So I put up my art panel with the ply on the front side and took down the eps panel.

It is still too loud , the photo shows this.

The upper dotted line is the new art panel the lower thick line is the actual real time response .

The new panel is between 5db to 10db louder ?

I'm going to have to swop them over to make sure that nothing has gone wrong with the amp ?

The responses seem similar but the larger ply panel handles the bass better, as I suspected.

Before I say anymore I'd better try and figure this out ?

Steve.

Attachments

That is very light. Spread tow I assume? I haven't been able to find it at a discount larger than 500mm wide. If that size makes sense for you then AliExpress has some for about $20/sheet at 1 meter by half meter. If you cut that in half it's one square panel inside and outside.Carbon should be lighter than glass, and the suppliers I have been looking at do have light carbon weave. Carbix.se has these figures for the weaves:

64g/m2 carbon:

Resin consumption: 46 g/m², laminate thickness: 0.064 mm, laminate weight: 110 g/m²

80g/m² glass:

Resin consumption: 63 g / m², laminate thickness: 0.088 mm, laminate weight: 143 g / m²

They also have 36g/m² aramid weave:

Resin consumption: 51 g/m², laminate thickness: 0,071 mm, laminate weight: 87 g/m²

I would stay away from the aramid. It soaks up a lot of resin and ends up with a less "woody" structure and more "plastic-y" if that makes sense. It's also weaker on compression than even glass, and a pain to cut.

I tried to post these pics last night but I guess it didn't work.

I've learned a lot. This thin tightly woven fiberglass is easier to work with than I expected. It doesn't really need tape on the edges for fraying.

Cleanly cutting XPS panels has been a pain in the *** but I've discovered quite counterintuitively that power tools work well at high speed. I'm even making nice mitre cuts and using epoxy as glue to form structures. The hardest part is clamping to set. The foam is floppy enough it needs bracing in more spots than I have clamps.

Now I have two nearly square 1/2 inch thick XPS panels With 1 inch XPS frames. One panel has a window with CF panel securely bonded in 4 corners and the other has a very thin fiberglass skin on one side (the back).

I've spent the morning cleaning them up and then temporarily attaching exciters and listening to one panel or the other as a left speaker and comparing to my big 6 foot panel.

Neither of them sounds as good as the big panel which makes sense because one exciter at a time. Both are very clean sounding but a little flat. Not surprising. More surprising is that each of them has a much weaker high frequency response than the big panel. And also less SPL overall. I suspect I may have constrained the edges too much. My big panel is not braces on the bottom edge and only half braced on the top and I the dress edges seem to be a source of a lot of the bass and the highs just from moving my ears around the panels. I may cut one side brace of...but it was a lot of work to get them here and if it sounds worse rather than better then I will have a sad.

I'm also considering not doing the fiberglass on the front of the solid panel as I don't think it would benefit from more stiffness.

While writing this I have music going and Riders on the Storm sounds about the best I've heard it in years. The new square isn't as good with cymbals or snare drums but it does really well with Jim Morrison's vocals.

I've learned a lot. This thin tightly woven fiberglass is easier to work with than I expected. It doesn't really need tape on the edges for fraying.

Cleanly cutting XPS panels has been a pain in the *** but I've discovered quite counterintuitively that power tools work well at high speed. I'm even making nice mitre cuts and using epoxy as glue to form structures. The hardest part is clamping to set. The foam is floppy enough it needs bracing in more spots than I have clamps.

Now I have two nearly square 1/2 inch thick XPS panels With 1 inch XPS frames. One panel has a window with CF panel securely bonded in 4 corners and the other has a very thin fiberglass skin on one side (the back).

I've spent the morning cleaning them up and then temporarily attaching exciters and listening to one panel or the other as a left speaker and comparing to my big 6 foot panel.

Neither of them sounds as good as the big panel which makes sense because one exciter at a time. Both are very clean sounding but a little flat. Not surprising. More surprising is that each of them has a much weaker high frequency response than the big panel. And also less SPL overall. I suspect I may have constrained the edges too much. My big panel is not braces on the bottom edge and only half braced on the top and I the dress edges seem to be a source of a lot of the bass and the highs just from moving my ears around the panels. I may cut one side brace of...but it was a lot of work to get them here and if it sounds worse rather than better then I will have a sad.

I'm also considering not doing the fiberglass on the front of the solid panel as I don't think it would benefit from more stiffness.

While writing this I have music going and Riders on the Storm sounds about the best I've heard it in years. The new square isn't as good with cymbals or snare drums but it does really well with Jim Morrison's vocals.

Hmm, no attachments againI tried to post these pics last night but I guess it didn't work.

I've learned a lot. This thin tightly woven fiberglass is easier to work with than I expected. It doesn't really need tape on the edges for fraying.

Cleanly cutting XPS panels has been a pain in the *** but I've discovered quite counterintuitively that power tools work well at high speed. I'm even making nice mitre cuts and using epoxy as glue to form structures. The hardest part is clamping to set. The foam is floppy enough it needs bracing in more spots than I have clamps.

Now I have two nearly square 1/2 inch thick XPS panels With 1 inch XPS frames. One panel has a window with CF panel securely bonded in 4 corners and the other has a very thin fiberglass skin on one side (the back).

I've spent the morning cleaning them up and then temporarily attaching exciters and listening to one panel or the other as a left speaker and comparing to my big 6 foot panel.

Neither of them sounds as good as the big panel which makes sense because one exciter at a time. Both are very clean sounding but a little flat. Not surprising. More surprising is that each of them has a much weaker high frequency response than the big panel. And also less SPL overall. I suspect I may have constrained the edges too much. My big panel is not braces on the bottom edge and only half braced on the top and I the dress edges seem to be a source of a lot of the bass and the highs just from moving my ears around the panels. I may cut one side brace of...but it was a lot of work to get them here and if it sounds worse rather than better then I will have a sad.

I'm also considering not doing the fiberglass on the front of the solid panel as I don't think it would benefit from more stiffness.

While writing this I have music going and Riders on the Storm sounds about the best I've heard it in years. The new square isn't as good with cymbals or snare drums but it does really well with Jim Morrison's vocals.

Yes, this is the product page (Swedish, but data in English): https://www.carbix.se/product.html/kolfibervav-flattow-62g/m2-plainThat is very light. Spread tow I assume? I haven't been able to find it at a discount larger than 500mm wide. If that size makes sense for you then AliExpress has some for about $20/sheet at 1 meter by half meter. If you cut that in half it's one square panel inside and outside.

I would stay away from the aramid. It soaks up a lot of resin and ends up with a less "woody" structure and more "plastic-y" if that makes sense. It's also weaker on compression than even glass, and a pain to cut.

About €75 m²

They also have lower weight glass, but like the aramid it looks more like a mesh than a fine weave.

Well, yes, the new panel is louder ?

A lot louder !

The bass peak is not as loud as the cascamite panel with 6x4 inch ply but this panel handles it much better and gives the panel a much flatter response curve.

So far it sounds very good too, but I need to do some more listening.

The low end drops off below 40hz still , so I am rolling this panel off at 45hz at the moment to stop the very low frequencies getting to the exciter, which helps stop unnecessary vibrations and power needs.

So this panel can go loud with my exciters, but probably could do with a little more push lower down , I could double up the exciters for more power or a more powerful exciter ?

I know that mounting my large ply panels in a very rigid frame increased the db output , but am a bit mystified as to why this panel should be louder.

I will have to now, make a panel out of the other half of the box to see if it is the material ?

But I think it is not ?

I will have to wait and see ?

Steve.

A lot louder !

The bass peak is not as loud as the cascamite panel with 6x4 inch ply but this panel handles it much better and gives the panel a much flatter response curve.

So far it sounds very good too, but I need to do some more listening.

The low end drops off below 40hz still , so I am rolling this panel off at 45hz at the moment to stop the very low frequencies getting to the exciter, which helps stop unnecessary vibrations and power needs.

So this panel can go loud with my exciters, but probably could do with a little more push lower down , I could double up the exciters for more power or a more powerful exciter ?

I know that mounting my large ply panels in a very rigid frame increased the db output , but am a bit mystified as to why this panel should be louder.

I will have to now, make a panel out of the other half of the box to see if it is the material ?

But I think it is not ?

I will have to wait and see ?

Steve.

I was thinking about how much suspension could affect SPL. With a free hanging panel it seems like there is a lot of phase cancellation. The sound does get more focused, especially the bass, when restricting the plate a bitWell, yes, the new panel is louder ?

A lot louder !

The bass peak is not as loud as the cascamite panel with 6x4 inch ply but this panel handles it much better and gives the panel a much flatter response curve.

So far it sounds very good too, but I need to do some more listening.

The low end drops off below 40hz still , so I am rolling this panel off at 45hz at the moment to stop the very low frequencies getting to the exciter, which helps stop unnecessary vibrations and power needs.

So this panel can go loud with my exciters, but probably could do with a little more push lower down , I could double up the exciters for more power or a more powerful exciter ?

I know that mounting my large ply panels in a very rigid frame increased the db output , but am a bit mystified as to why this panel should be louder.

I will have to now, make a panel out of the other half of the box to see if it is the material ?

But I think it is not ?

I will have to wait and see ?

Steve.

If you have a rigid mounting, the plate is no longer cancelling itself, but damping of the plate reduce the SPL.

With just the right amount of compliance is the suspension one should get a sweet spot where not much phase cancellation is happening, but where the plate is not too much dampened either.

Yes strange.Christian.

Sorry, but when I go into your link ,there is no text or figs ?

Very strange ?

Steve.

This is for US9660596B2 : main page / pdf

This is for WO2016118341A1 : main page / pdf

Perhaps just enter the patent reference in your search engine?

Christian

PS : for the WO2016118341A1 open the pdf. There is no figs in the "main google page".

Sorry for so many posts...

I realized my pictures are too big for the forum rules so that's why they aren't there.

Been experimenting....different driver positions and combos and panel positions and suspension or sitting....and nothing comes close to the high frequency response of the other panel. I'm wondering if the braced XPS is just too stiff. The 6 foot panel is quite wobbly. I think I have two very large pistons. In the smaller panels. Rather than cut the bracing off, I'm considering cutting some slots in the face along the edge to free up more movement.

I realized my pictures are too big for the forum rules so that's why they aren't there.

Been experimenting....different driver positions and combos and panel positions and suspension or sitting....and nothing comes close to the high frequency response of the other panel. I'm wondering if the braced XPS is just too stiff. The 6 foot panel is quite wobbly. I think I have two very large pistons. In the smaller panels. Rather than cut the bracing off, I'm considering cutting some slots in the face along the edge to free up more movement.

Do you have the possibility to predict also the stiffness?That is very light. Spread tow I assume? I haven't been able to find it at a discount larger than 500mm wide. If that size makes sense for you then AliExpress has some for about $20/sheet at 1 meter by half meter. If you cut that in half it's one square panel inside and outside.

I would stay away from the aramid. It soaks up a lot of resin and ends up with a less "woody" structure and more "plastic-y" if that makes sense. It's also weaker on compression than even glass, and a pain to cut.

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker