Let's hope we'll be able to talk about this at this year's BAF too if another pandemic not happens 🙂 I've just sent you an email with the files you have requested

Aleph 60Beautiful!

Hmmmmmmmmm.... what could go in those?.... 😀

M2 on one side, F6, Aleph J, or SissySIT on the other heatsink. Switch power supply back and forth to suit your mood

I’m going to throw a set of LuDEF boards in mine. The 400mm depth will be nice to keep the signal transformer away from the power transformer.

If the Dissipante does see some revisions toward the Monoblock internal structure it might be nice to have an option to order without heat sinks, just plain Aluminum sides. Would give us a wider 4U400 chassis to house a very nice dual mono power supply to them hook up to Monoblocks with the amplifier channels (Im thinking dual donuts with room for a CLC filtering).That's something we are definitely considering, we have done some small improvements on this chassis which have been requested for years (countersunk screws for the covers, covers predrilled to mount the antivibrations feet, better finishings) and they could be done on the Dissipante chassis as well

Yes, that's correct. Just like the Dissipante chassis all the parts can be customized

Speaking of which, I believe you mentioned earlier the width of the monoblock chassis is 210mm, what is the internal width?

I gather that UMS-drilled heat sinks will not be offered initially, but would have to be a custom option. If so, then to have 4 heatsinks drilled to UMS spec, would one have to pay the customization fee X 4 (one for each heat sink)?

FYI, I am looking at this development very carefully as 6L6 recently suggested that I build F5 Turbo mono blocks in 4U 400 mm chassis.

FYI, I am looking at this development very carefully as 6L6 recently suggested that I build F5 Turbo mono blocks in 4U 400 mm chassis.

Last edited by a moderator:

The chassis is wonderful! Great job!

I join the list of those who would like to have the 300mm version (due to lack of space)=)

I join the list of those who would like to have the 300mm version (due to lack of space)=)

If the Dissipante does see some revisions toward the Monoblock internal structure it might be nice to have an option to order without heat sinks, just plain Aluminum sides. Would give us a wider 4U400 chassis to house a very nice dual mono power supply to them hook up to Monoblocks with the amplifier channels (Im thinking dual donuts with room for a CLC filtering).

Speaking of which, I believe you mentioned earlier the width of the monoblock chassis is 210mm, what is the internal width?

The attached picture should help!

I gather that UMS-drilled heat sinks will not be offered initially, but would have to be a custom option. If so, then to have 4 heatsinks drilled to UMS spec, would one have to pay the customization fee X 4 (one for each heat sink)?

FYI, I am looking at this development very carefully as 6L6 recently suggested that I build F5 Turbo mono blocks in 4U 400 mm chassis.

There has never been an UMS spec for the 4U 400 chassis (4U 300 or 5U 400 only) so in case you need those holes it will count as an extra customization.

Since we have to drill the heatsinks one by one the customization fee will x 4 as you've said

The chassis is wonderful! Great job!

I join the list of those who would like to have the 300mm version (due to lack of space)=)

It all comes down to how popular the chassis can get, if we see there is enough interest we are more than happy to release new models 🙂

Attachments

you can't really expect them to have that in Shop

cooling is hysterically bad in that arrangement

I know it looks good, and no reason not to make it that way just for looks, but it can be sold only as that - article for looks, not performance

cooling is hysterically bad in that arrangement

I know it looks good, and no reason not to make it that way just for looks, but it can be sold only as that - article for looks, not performance

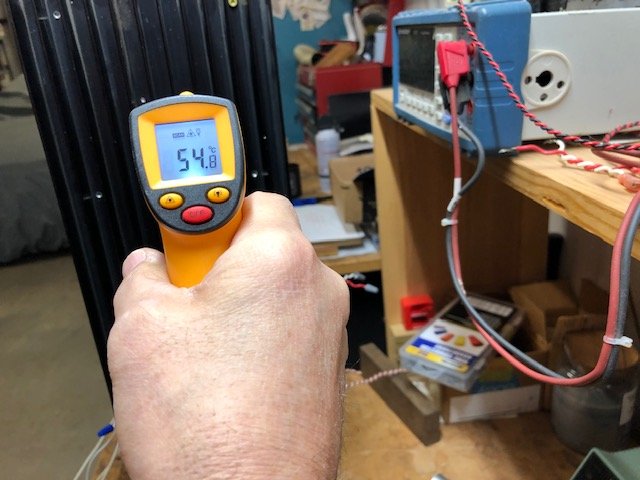

ZM I respect your opinions and info very much but i have to disagree respectively. Why couldn't something like that be in the shop? I'll agree with you completely if there is zero interest. As far as cooling being "hysterically bad" just makes no sense. First of all these were pulled from industrial 50HP drives that used the HS in the exact same configuration in closed cabinets. The pic in first frame is of the F5T in operation with each transistor biased to 1.5 amp. It's been running continuously for three days. The hottest spot is just above the topmost transistor at 54-55 Deg C. The second pic is of a Pass A-40 that I have been using for 15 years or more. I have never had an output transistor fail in that time.

Two heat sinks of equal area, fin size and spacing, one that is higher than wide and the other that is wider than high, with equal number of devices equally spaced, the wider than high heat sink will be more efficient and cooler if naturally ventilated (no forced air).

Ok I hear what you are saying and not arguing it. But how much more efficient? The statement that it is "hysterically bad" I think is an exaggeration. This being DIY I chose them BC they were free. With what would be considered high bias they seem to be doing an adequate job. I would probably lower bias a little to drop to steady 48-50 C. I have an identical HS that has been cut in half. It might be worth setting up experiment to test the performance and quantify. Lots of extra work though!

- Home

- Amplifiers

- Pass Labs

- New Monoblock chassis (sets!!!) from Modushop