Dayton exciters are hard to get right now. I like the Aiyimas:

https://www.aliexpress.com/i/32717606554.html

https://www.aliexpress.com/i/32717606554.html

That’s fantastic! Thanks for putting that together.Pepe

You could have a look to the pdf file I posted #4211. It will give you a view about some realizations, the related posts.

Hope you get some help filling in the few blanks.

Steve,I think my 5mm xps with epoxy coating is probably a better option, for me anyway.

Where do you get your 5 mm foam? And is it xps or eps you prefer? I seem to recall you liked eps especially, but this time you mentioned xps.

When I looked for eps some time ago, the thinnest I could find was 1". I sanded some of it down to 1/2 but never thinner.

Eric

What I imagine might work would be an EPS core, with plexiglass skins on both sides. But the plexiglass skins would have to be pretty thin, like 0.5 mm or less, I think. Much thicker and it wouldn't be much different from solid plexiglass, I think.I wonder if a plexiglass base with an EPS top layer can combine the low frequency response of the former with the "life" of the latter.

Eric

Christian,Another possibility which needs much much work (if feasible) is to make my own honeycomb.

How were you thinking of doing that? Some time ago I was thinking about making a kind of honeycomb by simply drilling an array of holes in a lightweight plywood, but I never did that. I'm curious what you had in mind. I suspect nomex would be hard to beat, unless you want a particular thickness that you can't get, or want a feature nomex doesn't provide.

Eric

So I did something today that I hadn't done yet which is to A-B my panels with some conventional speakers. The results were interesting, yet at the same time expected.

The speakers are the Dayton Audio B652, a budget powerhouse and a bargain HiFi darling for a few years now. Retail on them costs about the same as my panels cost me in raw materials, give or take a few bucks in Dayton's favor. I picked my pair up secondhand for 7 bucks to use as mules in my workshop, testing vintage receivers that I am restoring. I ran one off the same amp as my panels, a hand-built class AB running about 30wpc. I also ran them on the same EQ curve as my panels currently run through my DSPB-K board, crossed over at 115Hz at 18dB/oct to a Definitive sub. It's obviously not totally objective since there are a couple of >1.5dB tweaks on the panels. I ran one of my panels on the other channel, and switched the configuration mid-way to make sure it was balanced to my ears and the amp.

The big takeaways were that the Daytons had more impact and dynamism on things like snares, really bringing some presence and sizzle to them, whereas the panels sounded thin. The Daytons were thicker in the midbass as well, smoothing the transition between themselves and the sub. Through the mids and highs they were pretty much neck and neck, with the panels having a little more clarity/detail in most caees, and a smoother quality to the upper range, but with each performing admirably over a variety of music. That spectrum would be an argument of subjectivity based on how you like your sound. The biggest difference was that when I closed my eyes at midfield the DML essentially disappeared, and the Dayton I could pinpoint without a moment's hesitation. The stereo separation and staging were pretty stark compared to the panels. I thought the depth wasn't quite up to the panels either. At the same time the panels were a little more vague as far as placement. I'll take that over the split/cramped stage and beaming of the bookshelves though.

Again, not shocking per-se but it was fun to do. It was a pretty brief comparison, too. At the end of the day, the tonal qualities of the panels can be adjusted with some EQing to bring it closer to the Daytons but you'll likely not be able to make the bookshelves vanish into the Soundstage no matter what you do with placement. And the panels were frankly placed at a disadvantage, on top of a desk and about a foot from the wall. Place them both in their optimum places in the room and the DMLs will sound even better.

Anyway, that is my Sunday beers and beats report. 😁

The speakers are the Dayton Audio B652, a budget powerhouse and a bargain HiFi darling for a few years now. Retail on them costs about the same as my panels cost me in raw materials, give or take a few bucks in Dayton's favor. I picked my pair up secondhand for 7 bucks to use as mules in my workshop, testing vintage receivers that I am restoring. I ran one off the same amp as my panels, a hand-built class AB running about 30wpc. I also ran them on the same EQ curve as my panels currently run through my DSPB-K board, crossed over at 115Hz at 18dB/oct to a Definitive sub. It's obviously not totally objective since there are a couple of >1.5dB tweaks on the panels. I ran one of my panels on the other channel, and switched the configuration mid-way to make sure it was balanced to my ears and the amp.

The big takeaways were that the Daytons had more impact and dynamism on things like snares, really bringing some presence and sizzle to them, whereas the panels sounded thin. The Daytons were thicker in the midbass as well, smoothing the transition between themselves and the sub. Through the mids and highs they were pretty much neck and neck, with the panels having a little more clarity/detail in most caees, and a smoother quality to the upper range, but with each performing admirably over a variety of music. That spectrum would be an argument of subjectivity based on how you like your sound. The biggest difference was that when I closed my eyes at midfield the DML essentially disappeared, and the Dayton I could pinpoint without a moment's hesitation. The stereo separation and staging were pretty stark compared to the panels. I thought the depth wasn't quite up to the panels either. At the same time the panels were a little more vague as far as placement. I'll take that over the split/cramped stage and beaming of the bookshelves though.

Again, not shocking per-se but it was fun to do. It was a pretty brief comparison, too. At the end of the day, the tonal qualities of the panels can be adjusted with some EQing to bring it closer to the Daytons but you'll likely not be able to make the bookshelves vanish into the Soundstage no matter what you do with placement. And the panels were frankly placed at a disadvantage, on top of a desk and about a foot from the wall. Place them both in their optimum places in the room and the DMLs will sound even better.

Anyway, that is my Sunday beers and beats report. 😁

EricChristian,

How were you thinking of doing that? Some time ago I was thinking about making a kind of honeycomb by simply drilling an array of holes in a lightweight plywood, but I never did that. I'm curious what you had in mind. I suspect nomex would be hard to beat, unless you want a particular thickness that you can't get, or want a feature nomex doesn't provide.

Eric

It is perhaps a silly idea or at least something that takes hours... Not tested.

The straws (the one to put in a glass to drink) are now made of paper mainly; they are 6mm diameter by a bit less 200mm long. By gluing them together you get a rectangular assembly. Then make slices with a sharp knife. A tool should be necessary to insure the repeatability of the thickness. Those basic elements can be then glued together on a skin. I think about a skin of 1mm balsa boards for examples.

This will give you perhaps better ideas.

Christian

The staging is also for me a big difference with more conventional loudspeakers. My plywood panels are for now laying along my old columns but even like that they sound better. Not by the "linearity" of the frequency response but by the image, the transients.So I did something today that I hadn't done yet which is to A-B my panels with some conventional speakers. The results were interesting, yet at the same time expected.

... the panels were frankly placed at a disadvantage, on top of a desk and about a foot from the wall. Place them both in their optimum places in the room and the DMLs will sound even better.

The reflection of the rear wave was mentioned in previous (old?) post as key point... I think I read things for example from Burntcoil between what he did in France or in London. With no care or probably because most of us can't place the panels in a better position, we don't get the best.

This point should be common to what happen with OB (Open Baffle).

By the nature of the problem, I wonder if EQ can solve it or simply it reduces the effect.

What about solution to have the panels less sensitive to the rear wall ? Some diffusor / absorber ?

Veleric.

I think this is the xps board I used ,it is just like the 1inch xps board but thinner.

don't get the softer type which bends more and feels more rubbery and soft !!

some diy stores stock this for laminate flooring.

I have not used the fiberglass ,just the epoxy for coating , so far, but it makes a good sounding panel.

It would be interesting to see if the strength could be increased with minimal weight as in the tech ingredients YouTube video.

https://www.ebay.co.uk/itm/XPS-Foam...a-3ca0-4669-b54c-26d28854e67f&redirect=mobile

Steve

I think this is the xps board I used ,it is just like the 1inch xps board but thinner.

don't get the softer type which bends more and feels more rubbery and soft !!

some diy stores stock this for laminate flooring.

I have not used the fiberglass ,just the epoxy for coating , so far, but it makes a good sounding panel.

It would be interesting to see if the strength could be increased with minimal weight as in the tech ingredients YouTube video.

https://www.ebay.co.uk/itm/XPS-Foam...a-3ca0-4669-b54c-26d28854e67f&redirect=mobile

Steve

There are a number of core material used when laminating sandwich constritions that could be good in combination with wood, CF, GF etc…

Airex is one of the core materials that comes to my mind. One thing to look for (I think) is the type of constrution it is ment for. Example, there are a lot of core material that is ment to make construction of complex shapes easy and are there for very flexible and less ”supportive” then a core material ment for flat surface with high stiffnes as prioritet.

Kind of obvious of one is used to laminate but maybe not if lamination is a field.

For example a lot of the core material used when laminating boats are quite flexible, so maybe less optimal for DMLs.

Just a thought.

Airex is one of the core materials that comes to my mind. One thing to look for (I think) is the type of constrution it is ment for. Example, there are a lot of core material that is ment to make construction of complex shapes easy and are there for very flexible and less ”supportive” then a core material ment for flat surface with high stiffnes as prioritet.

Kind of obvious of one is used to laminate but maybe not if lamination is a field.

For example a lot of the core material used when laminating boats are quite flexible, so maybe less optimal for DMLs.

Just a thought.

I have also this kind of material in stock (the green version) ... I thought to use it as core material with some reinforcement (balsa rod) between 2 balsa skins.Veleric.

I think this is the xps board I used ,it is just like the 1inch xps board but thinner.

don't get the softer type which bends more and feels more rubbery and soft !!

some diy stores stock this for laminate flooring.

I have not used the fiberglass ,just the epoxy for coating , so far, but it makes a good sounding panel.

It would be interesting to see if the strength could be increased with minimal weight as in the tech ingredients YouTube video.

https://www.ebay.co.uk/itm/XPS-Foam...a-3ca0-4669-b54c-26d28854e67f&redirect=mobile

Steve

Have you describe somewhere the technique for epoxy coating? Some data about the resulting arial mass, bending stiffness?

Christian

Christian.

It's the darker green not the bright green !

The dark green is stiffer.

I have posted pictures of my build and recordings.

Steve.

It's the darker green not the bright green !

The dark green is stiffer.

I have posted pictures of my build and recordings.

Steve.

The exchanges at the end of December raised questions that led me to do some testing.

I think it could interest some of you.

Basically I wanted to see :

Some results are expected, others not!

Christian

Christian

I think it could interest some of you.

Basically I wanted to see :

- The frequency response of my canvas panel compare to an OB of same size made with a Visaton FRS8 (one available at home...)

- If it is possible to see something about the phase of the front wave and the rear wave of a DML compare to an OB

- If it is possible to see the effect of a rear wall for the panel, for the OB.

Some results are expected, others not!

- Frequency response : the frequency response of the panel clearly extends to the bass, not the OB. It was expected but better to see for me. The proximity measurement shows even a very good response. For now I don't explain the dip at 150hz seen at 75cm. Not present in the proximity FR, it seems to be a kind of boundary effect (recombination of the front and rear due to reflections). I found similar things with other panels (loss of low freq level due to the boundaries). An additional test shown it is not the floor. Additional investigations are needed (outdoor? extrabaffle?)

- Front wave / rear wave phase : at least for the primary emission (if secondary exits!), I haven't found waves in phase for DML. DML and OB behave about the same with the rear wave out of phase. The canvas DML has even the propoerty to have a rear FR very similar to the front. This is probably due to the low masking of the exciter compared to the FRS8

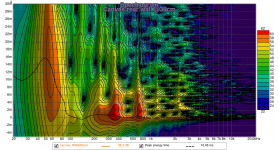

- Rear wall influence : the tests where done for different distances (1m, .5, .3, .2, .1, .05m). I had first a look to the FR (without windowing) where we can see peaks linked to the rear wall distance. The 30cm standard is confirmed to be critical... Using the spectrogram function (wavelet 1/6 octave) make clear the reflections. If we just look at the FR, the peaks for the canvas are a bit higher than the OB ones. The canvas has perhaps the advantage to keep the reflections more consistent with the main signal than for the OB. So for now with this test nothing to explain the reputation of a better behavior of the DML against the boundaies. It is perhaps just written in the basic DML characteristic which is its low directivity. One result of this test for me is the use of the wavelet spectrogram to visualize the reflections (I attach on here in addition). I like the wavelet analysis because I understand it much well than the FFT and it is close of how the hearing works. The difficulty is to understand which value to focus on as it gives an amplitude versus time (FFT gives only on value but masks the time).

Christian

Christian

Attachments

Steve,Just made some quick measurements of the panel ,one with the panel edge close to the ceiling as in the photo and one with the exciter side up close to the ceiling.

The microphone was lying on the listening area seat and the panel was about 2.5m in front, but on the ceiling.

The roll off in The top end is more to do with the CD and mic position.

Steve.

I think you got the same type of FR the one I got testing the influence of the rear wall (see #4311) with the effect of the rear wall bounces.

In the same post you will see also the contact of the canvas with a wall by the edge doesn't change a lot the FR. In my test it wasn't a vertical wall but the floor.

Christian

The thinnest I am seeing around here that's easy to get is about 2mm thick. Next question is where to put the exciter. I imagine the plexiglass sandwiched between the EPS and exciters would work best. I'm gonna run to Home Depot today and give it a tryWhat I imagine might work would be an EPS core, with plexiglass skins on both sides. But the plexiglass skins would have to be pretty thin, like 0.5 mm or less, I think. Much thicker and it wouldn't be much different from solid plexiglass, I think.

Eric

Why not just use aluminum flashing as the skins? You can get it very thin. You can trim it with a router. You can probably use contact adhesive to fasten it to the EPS.The thinnest I am seeing around here that's easy to get is about 2mm thick. Next question is where to put the exciter. I imagine the plexiglass sandwiched between the EPS and exciters would work best. I'm gonna run to Home Depot today and give it a try

Maybe this is a dumb question........... but what is the point of the skins? I'm not trying to be snarky; I'm genuinely asking. I am only looking to combine materials in the hopes of getting the best properties of both.Why not just use aluminum flashing as the skins? You can get it very thin. You can trim it with a router. You can probably use contact adhesive to fasten it to the EPS.

Speaking of which, I just tested (all 18"x24"):

- 1/8" acrylic alone (red)

- 1/16" acrylic alone (blue)

- 1/8" acrylic + 1" EPS (green)

Here is the 1/8" acrylic alone:

Not shabby at all. With very reasonable filters it looks like it will be able to get pretty smooth with EQ (sorry for the red on red):

I can't connect this to my DSP at the moment but I'd be the "life" I was looking for might come from the ~7dB boost from 10k up. More importantly, it will be so nice to not have my sub filling in all the way up to like 250 hz. It's annoying for stuff like panned toms to get all scrambled because of the higher bass coming out of the sub. I should be able to set my sub's HPF around 70-80 Hz which will be great.

Oh and even better- with the Aiyimas I can screw/unscrew the mount and bolt the exciters directly to the panel. Hopefully that will help with efficiency and response. I just hope this performance translates well to the listening space. I think with enough exciters, watts and EQ these could possibly do "bookshelf" full range.

A word on the 1/16" panel- it was way too flabby. 1/8" is a lot more rigid. Seems to help a lot with taming resonances, albeit at the expense of efficiency. But like I said... watts are cheap, and so are these speakers.

Interesting!Maybe this is a dumb question........... but what is the point of the skins? I'm not trying to be snarky; I'm genuinely asking. I am only looking to combine materials in the hopes of getting the best properties of both.

Speaking of which, I just tested (all 18"x24"):

- 1/8" acrylic alone (red)

- 1/16" acrylic alone (blue)

- 1/8" acrylic + 1" EPS (green)

My second panel was a 9mm XPS 50x60cm PVA coated (so light and flexible) and I got from it a FR similar to your 1/16" : a kind of bad bandpass. No bass, no treble. If somebody has explanation/hypothesis...

The 1/8" is surprisingly flat for a panel close to a "wall". What was the mic distance for your measurements? Would you share the Impulse Response and the spectrogram of this one (wavelet, 1/6oct as REW proposes. See my post 4313).

What is the weight of such a panel ? 1kg for 18x24x1/8?

Christian

I think part of the good low end was the panel basically being on the floor. Still, the 1/16" looked a lot like my EPS panels when I measured them long ago, so I think there is something to this thing's heft. It def feels hefty... Amazon says a sheet like this is about 3kg which seems nuts but not too far off.Interesting!

My second panel was a 9mm XPS 50x60cm PVA coated (so light and flexible) and I got from it a FR similar to your 1/16" : a kind of bad bandpass. No bass, no treble. If somebody has explanation/hypothesis...

The 1/8" is surprisingly flat for a panel close to a "wall". What was the mic distance for your measurements? Would you share the Impulse Response and the spectrogram of this one (wavelet, 1/6oct as REW proposes. See my post 4313).

What is the weight of such a panel ? 1kg for 18x24x1/8?

Christian

I will need to wait until the kids are gone and the house is quiet to get the impulse response. I saw your PDF- that is honestly beyond my ability lol. If you tell me the measurements you need I can do them and send you the data to analyze. I measured the panel on the floor with a UMIK-1 about 0.8m or so away. Based on your report it looks like I can do that again for my other measurements. I guess floor gain doesn't hit from 100Hz and up.

Your PDF has me intrigued about the canvas panels I have sitting around. Problem is they are huge and kind of flappy. Is the face of one of your canvas panels very taut? The response with and without the wall looks really good. On page 5 what is the difference between the red and green graphs? It does look like these panels need room for the low end to work based on your data. Still, ~50-400Hz is def tunable. That's pretty crazy. How do they sound with music?

I also ordered some 400x500x2mm carbon fiber panels. They are very stiff, but they are very light (duh). They make me want to try the 1mms. What I'm hoping is that they can match the response of the 1/8" acrylics but maybe with higher efficiency. If I have time I will try my canvas panels too.

Last edited:

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker