There are two power supply electrolytics on the board and a couple in the bias circuits that are low hanging fruit, but I don't think I would bother unless you hear noise or the bias gets off.

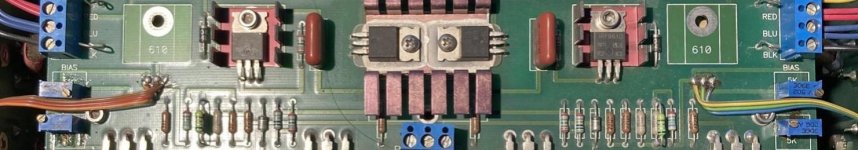

These are the seven electrolytics I can find on the main PCB.

Can you point me out which of these are potential 'low hanging fruit'?

https://www.diyaudio.com/forums/attachment.php?attachmentid=994916&stc=1&d=1636022580

Attachments

Last edited:

These are the seven electrolytics I can find on the main PCB.

Can you point me out which of these are potential 'low hanging fruit'?

https://www.diyaudio.com/forums/attachment.php?attachmentid=994916&stc=1&d=1636022580

Pa meant those big ones, mounted upside down, as hanging ones

I thought he meant it only in the metaphorical sense as apples ripe to fall off the three. But your explanation is better I think.

And a couple of electrolytics in the bias circuit, which are these?

And a couple of electrolytics in the bias circuit, which are these?

most likely 5 and 6 , on your pictures

have to time right now to look in Books from Yore, but - if you're going to change anything, change them all on FE pcb

have to time right now to look in Books from Yore, but - if you're going to change anything, change them all on FE pcb

Okay, thanks clear. It would be inefficient to let a couple of them in so you have to replace those within a year again I reckon.

Low hanging fruit meaning easily accessed, not necessarily needing replacement.

From the Aleph 1.2 Owners Manual

"The amplifier does not require any maintenance. While the design is conservative, this is a hard running amplifier, as single ended Class A operation is the least efficient operating mode.

In fifteen years the electrolytic power supply capacitors will get old. Depending on usage, you will begin to have semiconductor and other failures between 10 and 50 years after date of manufacture.

Later, the sun will cool to a white dwarf, and after that the universe will

experience heat death."

Did you write this?

most likely 5 and 6 , on your pictures

have to time right now to look in Books from Yore, but - if you're going to change anything, change them all on FE pcb

Missed one small 4.7uF 35V lytic on the PCB

So as far as I can see there are in total 14 electrolytic capacitors in one X600 chassis.

1 & 4 are 1000uF, 100V snapins

2 & 3 are 3300uF, 35V straight wire

5 & 6 are 100uF 25V straight wire

7 & 8 are 4.7uF 35V straight wire

All these caps are 105 C* degrees

And six 25.000uF, 75V screw terminals.

I sourced every lytic but with a long lead time for the six filtercaps which I do not mind.

Question: apart from 7 & 8 is the capacitance in uF critical as long as the voltage rating is as specified or somewhat above this rating.

I wish to keep the dimensions in diameter and length to be the same for all caps and that means that most of them will have a higher capacitance.

https://www.diyaudio.com/forums/attachment.php?attachmentid=995481&stc=1&d=1636215747

Attachments

One question I have when it comes to amps like this, where it is pretty much always centered on the caps; does anyone do anything for the transistors? Like possibly gently lifting them, cleaning and apply a type of thermal compound?

If anyone does that, what type of compound would be recommended? I picked up an Adcom GFA-5800 that I will get to someday and was looking to see what people do besides caps.

Thanks, James

If anyone does that, what type of compound would be recommended? I picked up an Adcom GFA-5800 that I will get to someday and was looking to see what people do besides caps.

Thanks, James

Well that's fine then because I've lost mine recently...in general, going up 50% in capacitance is no brain required

One question I have when it comes to amps like this, where it is pretty much always centered on the caps; does anyone do anything for the transistors? Like possibly gently lifting them, cleaning and apply a type of thermal compound?

If anyone does that, what type of compound would be recommended? I picked up an Adcom GFA-5800 that I will get to someday and was looking to see what people do besides caps.

Thanks, James

if visual inspection leads to conclusion that thermal interface is critical, then yes

also torque check

I hope that there aren't any Elna Long Life caps on the frontend boards as there were on mine Adcom GFA-585 because spilled their corrosive liquid as first!One question I have when it comes to amps like this, where it is pretty much always centered on the caps; does anyone do anything for the transistors? Like possibly gently lifting them, cleaning and apply a type of thermal compound?

If anyone does that, what type of compound would be recommended? I picked up an Adcom GFA-5800 that I will get to someday and was looking to see what people do besides caps.

Thanks, James

https://www.diyaudio.com/forums/attachment.php?attachmentid=995526&stc=1&d=1636224236

https://www.diyaudio.com/forums/attachment.php?attachmentid=995523&stc=1&d=1636224236

https://www.diyaudio.com/forums/attachment.php?attachmentid=995524&stc=1&d=1636224236

https://www.diyaudio.com/forums/attachment.php?attachmentid=995525&stc=1&d=1636224236

Attachments

if visual inspection leads to conclusion that thermal interface is critical, then yes

also torque check

This differential inputpair is thermally coupled and maybe need a reset...

https://www.diyaudio.com/forums/attachment.php?attachmentid=995530&stc=1&d=1636226222

https://www.diyaudio.com/forums/attachment.php?attachmentid=995531&stc=1&d=1636226222

https://www.diyaudio.com/forums/attachment.php?attachmentid=995532&stc=1&d=1636226222

Attachments

- Home

- Amplifiers

- Pass Labs

- PassLabs X600