Pway.

I have posted this one quite a few times over the years.

This is from about 1960, but this technology goes back to about the 30s or before ? Long before cone speakers

They called them sound boards in those days , which I think describes them better.

steve.

I have posted this one quite a few times over the years.

This is from about 1960, but this technology goes back to about the 30s or before ? Long before cone speakers

They called them sound boards in those days , which I think describes them better.

steve.

Steve,

OK, let's get into action. I have several projects that I would like to try with DMLs.

The exciters I will be using are the Aiyimas I can get through Aliexpress. Close to impossible to get the Daytons.

Aiyima has a screwable version which I prefer, over glue, to hold it to the panel. All fine with that?

Anything that will be affected?

From what I have seen the panels can be flat, without eq, from 300Hz to 20KHz. Is that right?

I can't and will not use any active eq to flatten the panel curve. So if there is some material what would work better with no eq, please do tell.

My panel of choice are the canvas type, treated with paint as you described. Would that provide the flat response I aspire: +/- 3dB?

The initial application would be as a nearfield speaker on my audio editing PC. Size: 50cm x 50cm. Distance from wall: 20cm.

Bandpass sub for 40Hz-300Hz +/- 3dB.

Separate amplifiers, of course.

If there's some design on the topic pages that would work for this, please tell

me which would be. Also the tips on how to improve the response.

Thanks in advance.

OK, let's get into action. I have several projects that I would like to try with DMLs.

The exciters I will be using are the Aiyimas I can get through Aliexpress. Close to impossible to get the Daytons.

Aiyima has a screwable version which I prefer, over glue, to hold it to the panel. All fine with that?

Anything that will be affected?

From what I have seen the panels can be flat, without eq, from 300Hz to 20KHz. Is that right?

I can't and will not use any active eq to flatten the panel curve. So if there is some material what would work better with no eq, please do tell.

My panel of choice are the canvas type, treated with paint as you described. Would that provide the flat response I aspire: +/- 3dB?

The initial application would be as a nearfield speaker on my audio editing PC. Size: 50cm x 50cm. Distance from wall: 20cm.

Bandpass sub for 40Hz-300Hz +/- 3dB.

Separate amplifiers, of course.

If there's some design on the topic pages that would work for this, please tell

me which would be. Also the tips on how to improve the response.

Thanks in advance.

Carlmart,

When I painted mine, I thinned the acrylic paint 1:1 with water. The color and coverage seemed to be the same as undiluted. Don't forget to paint the backside.

When I painted mine, I thinned the acrylic paint 1:1 with water. The color and coverage seemed to be the same as undiluted. Don't forget to paint the backside.

Pway.

I have posted this one quite a few times over the years.

steve.

Did you omit a link or image here?

Cheapvega.

As you know , my 30cmx42.5cm canvas panel with 6x4inch 2mm ply goes down to 40hz before roll off ,and that is with only a ten watt exciter, a more powerful exciter might improve on this ?

You could try a slightly larger canvas panel to see if this improves things, but nothing is garenteed and if too large could cause other problems ?

Because the canvas is quite lossy and also damps the panel to some extent,i would place the exciter in the centre to keep the balance for low frequencies.

If two exciters are needed for some reason ? You could use the nxt positions and still keep the balance.

540g seems a little too heavy to me, I would use some sort of brace at the back to support this.

When I tightened my panel the the roll off started higher at about 100hz.

There is no garentee of a better sound or frequency extention with Cf , but it would be interesting to find out ,if not too expensive?

What I would do with a 1mm Cf panel would be totally different to you and I'd be tempted to try the .5mm as well.

These would be small panels.

Steve.

I did not realize the canvas was lossy. I do have ample power to drive these panels but I'd also like to protect the exciters. Regarding the CF I am thinking of using fiberglass panels instead. They are a lot cheaper and I imagine will have similar performance in an acoustic application.

One thing I did notice is that the epoxy is still very flexible? Very similar to pva ,I was hoping for more rigidity ,something like cascamite but without the cracking.

Have I the wrong epoxy ?

Steve.

Epoxy has a lot of variations in formulation. 5 minute epoxy for example stays soft even when cured. Heat cured laminating resin has a sharp ring to it, very stiff. In a composite structure it holds the fiber in place, they carry the load. When using it as a paint layer, there is no guarantee it will be stiffer than shellac, or PVA or another material.

Determining Epoxy's Physical Properties - Epoxyworks

The flexural character is the material is the key. The thinnest amount of glass or carbon veiling would be much stiffer. The matrix that you hold it to a thin panel would probably not even matter. PVA, spray paint, any drying liquid that would wet it out and be able to be applied even and thin.

RC groups will have more information on veil in combination with foam and application methods. Carbon Fiber Veil cloth - RC Groups

Hi Steve,

Do we have a reference design/build log/info to refer for a DML speaker ( and preferred panel material like using canvas/ plywood/ foam / ceiling tiles etc), to be used with or without subwoofer.

Generally from the messages in the forum, it seems to be still work in progress or experimental phase.

From the given exciters given in below link which one we may prefer:

Bass Shaker / Exiter

I'm always looking for new materials, my personal favourite is eps, I also like card and veneer which are smaller panels bit still have a very wide frequency response.

But it all depends on what you do to them that makes them sound good or bad.

Over the years I have shown in great detail how to treat these panels for good sound .

These are all projects that I feel work and sound good , then I move on to the next.

But in general people tend to do their own thing based on something they read somewhere and end up screwing it up,in my opinion, that is.

The 5mm xps which I am now working on has been lying around for about 10 years , because I could not get a satisfactory sound from it,good as it was , it just wasn't good enough.

Could this now be added to my favourite materials list ? We shall see.

As for the exciters you showed.

https://diyaudiocart.com/Raw-Driver...io-DAEX25Q-4-Quad-Feet-25mm-Exciter-20W-4-Ohm

I can only recommend ,what I know.

This exciter looks the closest to my exciters, but it needs to come out of its plastic encasement.

Unless you can find the naked exciter without this?

Steve.

Sorry pway,should not post when I'm in a rush !

US3236958A - Loudspeaker system

- Google Patents

Steve.

US3236958A - Loudspeaker system

- Google Patents

Steve.

Steve,

OK, let's get into action. I have several projects that I would like to try with DMLs.

The exciters I will be using are the Aiyimas I can get through Aliexpress. Close to impossible to get the Daytons.

Aiyima has a screwable version which I prefer, over glue, to hold it to the panel. All fine with that?

Anything that will be affected?

From what I have seen the panels can be flat, without eq, from 300Hz to 20KHz. Is that right?

I can't and will not use any active eq to flatten the panel curve. So if there is some material what would work better with no eq, please do tell.

My panel of choice are the canvas type, treated with paint as you described. Would that provide the flat response I aspire: +/- 3dB?

The initial application would be as a nearfield speaker on my audio editing PC. Size: 50cm x 50cm. Distance from wall: 20cm.

Bandpass sub for 40Hz-300Hz +/- 3dB.

Separate amplifiers, of course.

If there's some design on the topic pages that would work for this, please tell

me which would be. Also the tips on how to improve the response.

Thanks in advance.

Carlmart

I cannot speak for Steve or what the outcome of the following might be, but here's what I plan to do over the next few days.

I have on order some 10mm ultra high density EPS (60x40cm) and some 40x30cm stretched triple gessoed canvas panels. I already have 2 x Tectonic 30w exciters.

I will be trying the following (in no particular order):

1. 400 x 550mm (Silver Ratio) free floating EPS panel operating from about 300hz upwards, beginning with sanding, rounded corners and a little bit of PVA where the exciter is going (Monacor 3/7 + 4/9 position)

2. 400 x 300mm canvas panel with 120 x 88mm (silver ratio) UHD EPS attached centrally with the exciter in the Monacor position relative to the panel as a whole. The small EPS section will be rounded, sanded and again with some PVA just where the exciter goes.

I will not be using diluted PVA on the panels or canvas in the first instance. You can always add, but taking away is more difficult. The UHD EPS I will be using should offer better high end response without EQ than the plywood I'm currently using.

How is it all going to sound and measure? I haven't a clue! But I do have a calibrated UMIK-1 and REW, so will be able to take some measurements. A caveat to all this is that how they sound and measure in my listening room will not be the same as they would in yours. I have about 1.5m between my existing panels and the rear wall, and the soundstage fills the room behind them. I forgot to mention that I run them with a Monacor 15 inch PA driver per side, up to crossover (anywhere from 300 to 500 hz, 24db LR).

I use a miniDSP HD for XO and EQ with a TPA3255 amplifier module per side. I also have a crude prototype passive pre stage for volume control.

The bottom line in all of this is that the only way to learn what's going to work is by doing it, based on the best experiences of others. This time around, I'll be trying something a little different: using a small EPS panel attached to the canvas rather than the plywood used in some setups. Part of the rationale for this is that UHD EPS should be better at the very top end. In addition if we get that extended top end radiating to the rear as well, then we may get more 'air'. Some of the best 'point and squirt' box speakers have rear or upward facing tweeters to achieve this.

Back in the mists of time in this mammoth thread, I recall DMBLES waxing lyrical about the naturalness of the canvas panels, but ultimately was unsatisfied by the top end. I'm speculating that my EPS implementation may be an improvement. The next few days should tell!

Stratoton.

Thanks again.

I was originally trying to get as hard a surface as possible, too hard realy,just to see what happens.

Similar to the tech ingredients video on hardening experiments ,but they used fiberglass,which I'm not sure I want?

But I always prefer(so far ) more flexible materials,enough to aid the vibrations in some way without the harsh sound.

The epoxy seems to be hardening a little more but the panel is still flexible.

I'm going to have to make another similar panel but this time coat it with the roller for a smoother finish both sides.

Is the thinner coating better than the thicker coating ? I wonder ?

Luckily I purchased a pack of 19 panels ,they were supposed to be used for under floor insulation.

I must have at least 12 left for experimenting.

The reason I missed putting the link on pways post was actually the low level detailed sounds that kept making my ears ping around,which kept making me look up,that and the fact my wife was about to serve up dinner😀

At the moment I'm using an old eps panel on the other channel so it's difficult to tell which is doing what.

Steve

Thanks again.

I was originally trying to get as hard a surface as possible, too hard realy,just to see what happens.

Similar to the tech ingredients video on hardening experiments ,but they used fiberglass,which I'm not sure I want?

But I always prefer(so far ) more flexible materials,enough to aid the vibrations in some way without the harsh sound.

The epoxy seems to be hardening a little more but the panel is still flexible.

I'm going to have to make another similar panel but this time coat it with the roller for a smoother finish both sides.

Is the thinner coating better than the thicker coating ? I wonder ?

Luckily I purchased a pack of 19 panels ,they were supposed to be used for under floor insulation.

I must have at least 12 left for experimenting.

The reason I missed putting the link on pways post was actually the low level detailed sounds that kept making my ears ping around,which kept making me look up,that and the fact my wife was about to serve up dinner😀

At the moment I'm using an old eps panel on the other channel so it's difficult to tell which is doing what.

Steve

This kit seems ideal for a DML system plus two subs.

Xh-a310 bluetooth 5.0 tda3116d2 digital amplifier board four-channel dual bass dual stereo 2*50w+2*100w audio amplifiers with the tuning Sale - Banggood.com

Xh-a310 bluetooth 5.0 tda3116d2 digital amplifier board four-channel dual bass dual stereo 2*50w+2*100w audio amplifiers with the tuning Sale - Banggood.com

Steve,

OK, let's get into action. I have several projects that I would like to try with DMLs.

The exciters I will be using are the Aiyimas I can get through Aliexpress. Close to impossible to get the Daytons.

Aiyima has a screwable version which I prefer, over glue, to hold it to the panel. All fine with that?

Anything that will be affected?

From what I have seen the panels can be flat, without eq, from 300Hz to 20KHz. Is that right?

I can't and will not use any active eq to flatten the panel curve. So if there is some material what would work better with no eq, please do tell.

My panel of choice are the canvas type, treated with paint as you described. Would that provide the flat response I aspire: +/- 3dB?

The initial application would be as a nearfield speaker on my audio editing PC. Size: 50cm x 50cm. Distance from wall: 20cm.

Bandpass sub for 40Hz-300Hz +/- 3dB.

Separate amplifiers, of course.

If there's some design on the topic pages that would work for this, please tell

me which would be. Also the tips on how to improve the response.

Thanks in advance.

I think the flat response with no EQ is going to be tough. The way I see it, something like an ADAU1701 is dirt cheap, so if you're going to go through the trouble of measuring the speakers you might as well tune them. ESPECIALLY for critical listening like audio editing. I think you will be very satisfied with these panels after you tune them though.

Plus even if you get a nice plug and play DSP I think you will be in for less money than an equivalent set of traditional monitors. So I would personally let go of the no DSP thing... it doesn't seem like a productive restriction.

I have a question about testing:

What would be the best kind of epoxy or substance to use that would let me securely mount and dismount exciters from various surfaces? I will be using the Aiyimas which have a 50mm diameter metal mount, and I will be testing them on rigid surfaces like wood & FRP. I will probably test them in a downfiring configuration which will make things a lot easier. What do you think? Vaseline? Rubber cement?

What would be the best kind of epoxy or substance to use that would let me securely mount and dismount exciters from various surfaces? I will be using the Aiyimas which have a 50mm diameter metal mount, and I will be testing them on rigid surfaces like wood & FRP. I will probably test them in a downfiring configuration which will make things a lot easier. What do you think? Vaseline? Rubber cement?

Steve,

I can't and will not use any active eq to flatten the panel curve. So if there is some material what would work better with no eq, please do tell.

I didn't address this bit. I agree with cheapvega re. not ruling out EQ. I have experimented in the past with 'simple' designs that minimise crossover components in order to achieve a 'purer' result. All have been unsatisfactory in one way or another. Even the EPOS EP12 with no XO components on the bass/mid unit can be improved with a superior crossover.

GR Research have also commented that with respect to an ATC speaker they were modding and which is often used in studio monitoring. The top end response was a bit droopy. But if you monitor and mix the sound as played through unmodded speakers, the result will be over-bright.

If I was using a system for monitoring, I'd be wanting as flat a frequency response as possible at my listening position. This almost certainly will require a calibrated measuring mic together with either active EQ (e.g. using a miniDSP or something similar) or with passive components.

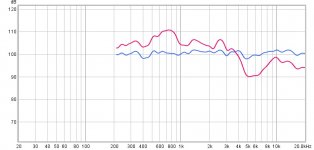

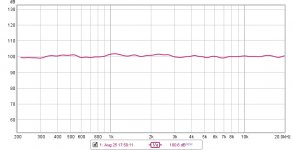

Attached is a plot showing before and after EQ. No need to say which is which! Without measuring how can one ever know where some of the key issues are? The second plot shows what can be achieved with appropriate EQ. This was for a 35 x 40cm experimental medium density EPS panel. Obviously, it's best to get as good a response as possible without any EQ.

Attachments

FYI, if you order Dayton exciters on PE they will ship as soon as they get some in stock. So it might be worth putting an order in even if w/e you want isn't available. I just got notification that DAEX32EP-4s I ordered just shipped. I think it took about a month. Now I'm not sure what to do with the Aiyimas I ordered. I honestly forgot I ordered these lol. I will play with all 3 (running SHFs now) and see what works best.

re: Parts-Express & Dayton Exciters

I had done the same for 4 "Thrusters", back when the Parts-Express site said:

I received the following from them earlier today:

Disappointing, but as likely due to COVID supply chain disruptions, understandable.

I had done the same for 4 "Thrusters", back when the Parts-Express site said:

We estimate this item will be in stock on 09/03/2021

I received the following from them earlier today:

Item #295-230 - Dayton Audio DAEX32EP-4 Thruster 32mm Exciter 40W 4 Ohm from order #SO1946494. We estimate this item will be in stock on 11/19/2021.

Disappointing, but as likely due to COVID supply chain disruptions, understandable.

UK Exciter Supply

UK exciter supply is pretty patchy at best. I've got some Monacors on backorder, but the date keeps getting pushed back.

UK exciter supply is pretty patchy at best. I've got some Monacors on backorder, but the date keeps getting pushed back.

Steve,

OK, let's get into action. I have several projects that I would like to try with DMLs.

The exciters I will be using are the Aiyimas I can get through Aliexpress. Close to impossible to get the Daytons.

Aiyima has a screwable version which I prefer, over glue, to hold it to the panel. All fine with that?

Anything that will be affected?

From what I have seen the panels can be flat, without eq, from 300Hz to 20KHz. Is that right?

I can't and will not use any active eq to flatten the panel curve. So if there is some material what would work better with no eq, please do tell.

My panel of choice are the canvas type, treated with paint as you described. Would that provide the flat response I aspire: +/- 3dB?

The initial application would be as a nearfield speaker on my audio editing PC. Size: 50cm x 50cm. Distance from wall: 20cm.

Bandpass sub for 40Hz-300Hz +/- 3dB.

Separate amplifiers, of course.

If there's some design on the topic pages that would work for this, please tell

me which would be. Also the tips on how to improve the response.

Thanks in advance.

LoOK at post 3424 for canvas panel response without ply panel, the response of the canvas panel with the ply panel is the same except the response goes down to 40hz.

If listening near field I wouldn't have thought a sub would be necessary?

I never recommended paint to coat the canvas ,I only use pva, paint is thick and heavy, pva is mainly water , even more so if thinned and literally soaks into the canvas,very light.

Don't try to tighten the panel as this will raise the low end response,unless you have a problem or a very loose panel.

Steve.

I have a question about testing:

What would be the best kind of epoxy or substance to use that would let me securely mount and dismount exciters from various surfaces? I will be using the Aiyimas which have a 50mm diameter metal mount, and I will be testing them on rigid surfaces like wood & FRP. I will probably test them in a downfiring configuration which will make things a lot easier. What do you think? Vaseline? Rubber cement?

I've always used bog standard double sided tape especially if using in a down firing configuration.

If your are standing the panel up you could use masking tape from the top of the panel to the exciter ,for short term support.

Steve.

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker