Yes, it can be done with just hot air but be careful not to melt the plastic holder for the 3 header pins. With the hotplate to do the majority of the preheating, only a minimal hot air from the top is needed.

@Zaman, thanks! Those are my favorite precision cutters and needle nose pliers by Lindstrom. The tweezers are same Techni-Tool that I have had for 20 years.

@Zaman, thanks! Those are my favorite precision cutters and needle nose pliers by Lindstrom. The tweezers are same Techni-Tool that I have had for 20 years.

Hi all!

X, I lost myself searching for some infos about LuFo Lite: requirements for preamp to reach full power? Value range for coils? Thanks

X, I lost myself searching for some infos about LuFo Lite: requirements for preamp to reach full power? Value range for coils? Thanks

12v to 19v (19v is to prevent destroying the LU1014D). At 12v and 1.3A bias current it can get something like 5w into 8ohms. 40mH and up size inductors. DCR can be larger as you want DCR plus external power resistor to add up to about 2ohms. For 0.5ohm inductor then use 1.5ohm resistor. Etc.

Oh, sorry - I thought you were asking what PSU rail voltages were needed.

This is a 0dB gain amp like MoFo or F4. 5w into 8ohms is about 18Vpp. So your preamp needs to be able to put out 6.32V rms.

This is a 0dB gain amp like MoFo or F4. 5w into 8ohms is about 18Vpp. So your preamp needs to be able to put out 6.32V rms.

Hi X.

I was toasting a panini last evening using our Breville griddle, like this;

Breville Sandwich/Panini Press and Toastie Maker, Stainless Steel [VST025] : Amazon.co.uk: Home & Kitchen

and while I was waiting I got to wondering about soldering the LU1014Ds to the adaptor boards with it so I measured the temperature of the hotplate - about 220°C

I think that's hot enough to get the job done, maybe with a little additional blast from my hot air station to get them over the line - it's nice that you can pre-heat the hotplate - any thoughts?

I have some Quik Chip solder paste (220°C melting point) on order so I guess I'll have to try assembling a couple of the adaptor boards using a couple of my Chinese-sourced LU1014Ds.

I'm thinking it might also serve to solder conventional PCBs with smd parts?

I was toasting a panini last evening using our Breville griddle, like this;

Breville Sandwich/Panini Press and Toastie Maker, Stainless Steel [VST025] : Amazon.co.uk: Home & Kitchen

and while I was waiting I got to wondering about soldering the LU1014Ds to the adaptor boards with it so I measured the temperature of the hotplate - about 220°C

I think that's hot enough to get the job done, maybe with a little additional blast from my hot air station to get them over the line - it's nice that you can pre-heat the hotplate - any thoughts?

I have some Quik Chip solder paste (220°C melting point) on order so I guess I'll have to try assembling a couple of the adaptor boards using a couple of my Chinese-sourced LU1014Ds.

I'm thinking it might also serve to solder conventional PCBs with smd parts?

Hi NB,

Yup, the hotplate/hot air method is how X and I get all our SMD work completed. It works very well. Get your hotplate/pan up to about 130-135°C with the loaded pcb and hit it with your hot air pencil from the top. Since the pcb and parts are already pre-heated the hot air makes the solder flow quickly. It will take some practice with the amount of paste to use (less is better) and how to move the hot air pencil. 😉

Larger components with plastic like smd electrolytic capacitors, relays and headers I will still use a fine tip iron so not to melt the plastic with the hotplate/air method.

Yup, the hotplate/hot air method is how X and I get all our SMD work completed. It works very well. Get your hotplate/pan up to about 130-135°C with the loaded pcb and hit it with your hot air pencil from the top. Since the pcb and parts are already pre-heated the hot air makes the solder flow quickly. It will take some practice with the amount of paste to use (less is better) and how to move the hot air pencil. 😉

Larger components with plastic like smd electrolytic capacitors, relays and headers I will still use a fine tip iron so not to melt the plastic with the hotplate/air method.

Last edited:

Yes, I was just moving along from X's griddle videos on Youtube - it just seems easier to use the plug-in griddle than the separate griddle/hob approach.

That will work but be careful not to contaminate your cooking surface for food. I use a dedicated old pan for smd and don’t cook food on it. The Pb or Bi etc can leach into the Teflon.

I heat the pan get PCB hot but below damage temp of elect. The hot air is local and quick.

I heat the pan get PCB hot but below damage temp of elect. The hot air is local and quick.

I wasn't able to do it with a heatgun alone, I used a steel plate on top of a camping stove then used the air to finish off as Vunce and X have indicated. I have seen integrated stations ( not expensive ) that heat the board and have air for smd - never thought I needed one but hindsight is 20/20 ..dB

I wasn't able to do it with a heatgun alone, I used a steel plate on top of a camping stove then used the air to finish off as Vunce and X have indicated. I have seen integrated stations ( not expensive ) that heat the board and have air for smd - never thought I needed one but hindsight is 20/20 ..dB

Could this plate be useful?

https://www.amazon.com/Remover-Heating-Soldering-Welding-Station/dp/B07W1ZZH8T/ref=sr_1_53?crid=Q06AIU4VS0C3&dchild=1&keywords=smd+desoldering+station&qid=1629137532&sprefix=smd+desolder%2Caps%2C282&sr=8-53

Last edited:

It's a curious listing -- in the top listing of characteristics it says 500 degrees, and down below, 250.

More options obviously on AliExpress. Example:

Led lamp bead desoldering station Preheating plate for heating plate LCD lamp strip desoldering BGA chip repair thermostat heat|Soldering Stations| - AliExpress

Led lamp bead desoldering station Preheating plate for heating plate LCD lamp strip desoldering BGA chip repair thermostat heat|Soldering Stations| - AliExpress

Hey X. For LuFo-Lite if I’m using flying leads for the IRF on the CapMx would you suggest a snubber board?

If you have the board go ahead and use it. It’s not critical though as you can also solder leads to the legs and cover with shrink tube.

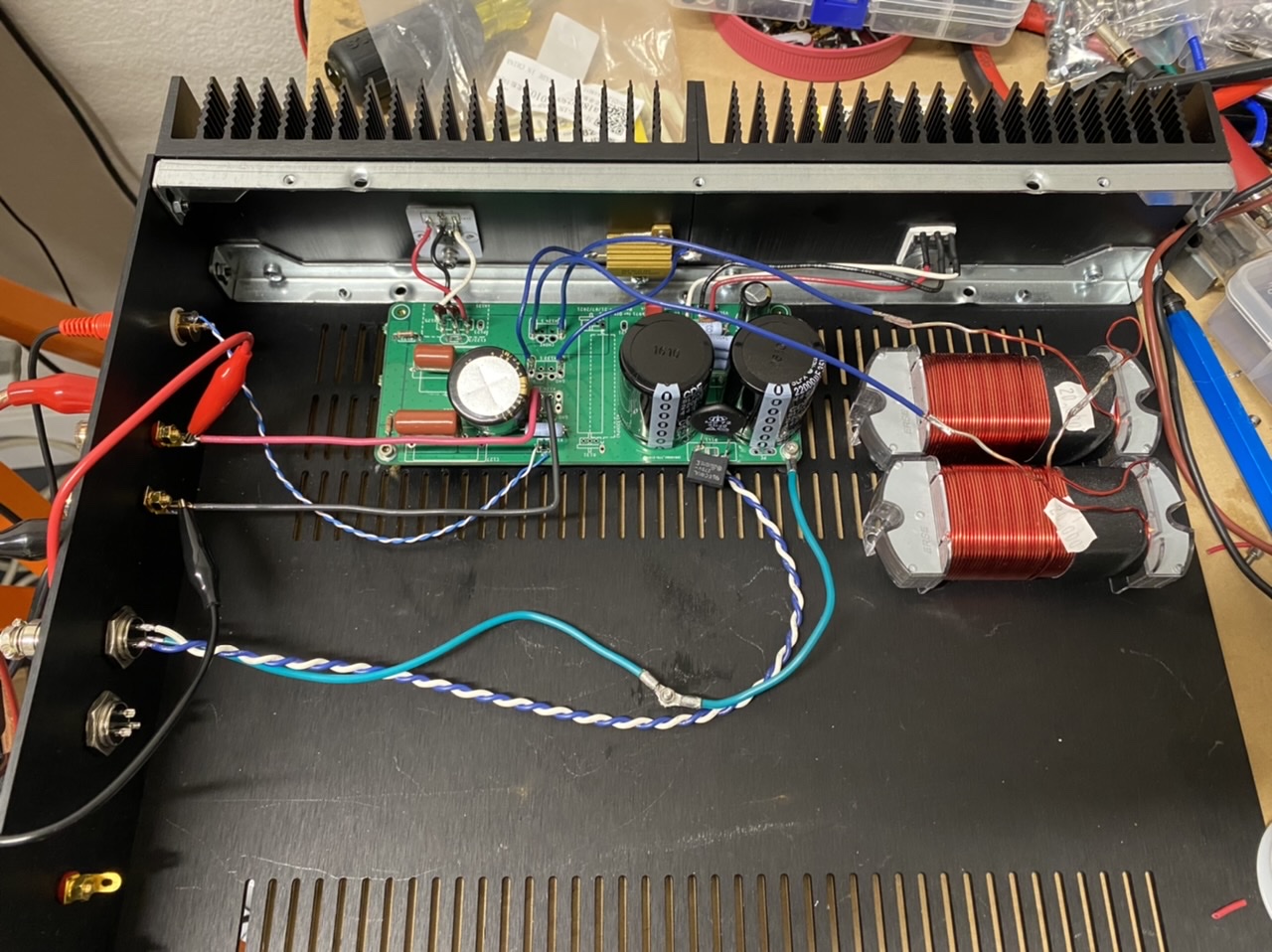

Jwjarch’s LuFo Lite is working out well on first verification build.

More details here:

LuFo Lite - a 1 Transistor SE Class A Headphone Amp

More details here:

LuFo Lite - a 1 Transistor SE Class A Headphone Amp

- Home

- Amplifiers

- Pass Labs

- LuFo Amp - 39w SE Class A from 28v Rail