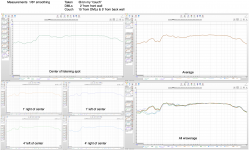

Thanks for the measurements aagas. I think they show one of the main benefits of DML which is the very even off axis response above the transition frequency. Are these graphs with eq?

Dave

Dave

Hi Dave,

No equalization at all.

Suggestions appreciated.

Maybe a little boost of the low and high end?

-- Andreas

No equalization at all.

Suggestions appreciated.

Maybe a little boost of the low and high end?

-- Andreas

Hi Andreas,

The overall response looks pretty smooth. Maybe you could add a high shelf at 10kHz with 6dB boost and low Q (1 or 2), but that's a matter of taste. You might also add a 6dB boost around 350Hz (Q=1or2). I've never had much luck below 150Hz with DML that's why I supplement with woofers below 250Hz. I'm using small (1'x2') carbon fiber with Nomex honeycomb core panels, so low end response is likely related to that.

Thanks,

Dave

The overall response looks pretty smooth. Maybe you could add a high shelf at 10kHz with 6dB boost and low Q (1 or 2), but that's a matter of taste. You might also add a 6dB boost around 350Hz (Q=1or2). I've never had much luck below 150Hz with DML that's why I supplement with woofers below 250Hz. I'm using small (1'x2') carbon fiber with Nomex honeycomb core panels, so low end response is likely related to that.

Thanks,

Dave

chisel -- The recording doesn't really do the the speakers justice. It sounds muffled and the soundstage sounds more forward. That said, it does give you some sense of how the speakers sound.

Imaginos.

Hi.

1 the nxt patent 4/9 x3/7 works for me,I also like the more central location,you can experiment with all the choices, and make your own choice.

2. A bead of neat pva on the exciter foot should do fine on uncoated ply.

3. A roll of double sided tape should keep it stuck enough for testing,just don't expect it to still be stuck next day.

Some 1inch masking tape could be used to support the magnet end ,taped to the top of the panel.

Which I have done.

This would last longer.

4.this you can also test yourself ,I would say not very much,I was disappointed.

But I wasn't using 5mm ply.

5.You are now in the realms of guess work,will what you do improve or or make things worse? And once it's glued on its not going to come off without damaging the panel.

Personally I think 5mm is stiff enough,it is up to you how much time and effort you want to put into the panel?

Steve.

Thanks for the info.

Imaginos,

Here are my own thoughts about your questions:

1. Put the two exciters in the vicinity of the center and move them both around until you find a combination of positions that works well. Probably you can skip positions that are outside of the middle third of the panel along either axis. Ideally you would test each combination with REW.

2. You can attach directly to smooth plywood, but if you seal the area first with a coat or two of polyurethane, you may be able to get the exciter off the panel later (should you need too) without delaminating the plywood.

3. If you mount you panels horizontally for testing, you can place a small piece of foam and a weight (maybe 100 or 200 grams) on top of the exciter that and it will keep the exciter from bouncing around.

4. That's what I do. And no, it's not nearly twice as loud. Barely louder at all in fact. But it's safer for your amp (if it's only designed for 8 ohms). Usually I can get a bit flatter response with two than I can with one.

5. I don't know. Worth a try if you would enjoy doing it, even if it doesn't work.

Eric

Thanks for this. I mounted a single exciter to each board and I am not satisfied with the perceived frequency response. I may add the 2nd exciters just in an effort to flatten it.

So I came into a few free bass shakers, are they worth mounting as 2nd (or even 3rd?) exciters? I am mostly satisfied with the highs, just want to address the lows.

One issue is that they are 16 ohm. In that case would I want to run them in parallel with the 4 ohm exciters I already have mounted?

This is the model: Dayton Audio TT25-16 PUCK Tactile Transducer Mini Bass Shaker 16 Ohm

Imaginos.

This is a picture of the next patent for up to 4 exciters .

Plus patent ,if you want to trawl through all the mind numbing words,but there is a lot of good info hidden in there.

US20060159293A1 - Acoustic device

- Google Patents

I did read this entire patent. I was able to get through it but the author was incredibly verbose!

Hi Imaginos,

I would put your bass exciters on their own panel. I found for a DML bass "subwoofer"

that size does matter and the panel should be at least 500 x500 mm and can be made from 3mm ply or carbon fiber panel

Cheers,

Steve

I would put your bass exciters on their own panel. I found for a DML bass "subwoofer"

that size does matter and the panel should be at least 500 x500 mm and can be made from 3mm ply or carbon fiber panel

Cheers,

Steve

Hi Imaginos,

I would put your bass exciters on their own panel. I found for a DML bass "subwoofer"

that size does matter and the panel should be at least 500 x500 mm and can be made from 3mm ply or carbon fiber panel

Cheers,

Steve

Well, my panels are about 300 x 1220mm. So the area is as big as your example. And it's 5mm ply so a bit stiffer

So treat this as an experiment to test out something new. I make no claim for any superior performance but obviously I hope for something interesting and good.

Here are the factors influencing the design.

1. Long and thin ply panels, in this case 0.3 M by 1.2M by 3mm thick, seem to reach down to 30Hz

2. Long and thin also seems to provide better mode distribution - hat tip to Veleric for that one

3. Non-parallel sides may also provide benefits - hat tip to Spedge and it is claimed by Farad Azima in his 1997 patent

4. Edge treatment via absorbing elastomeric layer to absorb edges reflection and simulate an ideal infinite plate

5. Single exciter per panel appears to be preferable - validated by various sources

6. And finally, multiple panels to allow higher SPL at 30Hz without reaching exciter excursion limit.

Images below illustrate the array.

Normally I would build it first and then let you know what happened but I can’t build anything until the lock-in in France ends in a few weeks time.

Please throw rocks and suggestions as you see fit.

Burnt

Imaginos.

Thin panels will reduce LF performance,but burntcoil used this method (tall blonds ,he called them) to enhance the low end.

You will have to trawl though the thread to find the exciter position,it was in a central position but quite near the top or bottom?

I did some tests with a similar panel,and I think it taps into the panel resonance? To produce more useful LF.

I'm not sure what was the end result of this project ,maybe because of covid ,it has been put on hold?

But you could try putting the two shakers either side of the central line near the top,you will have to experiment to find the right spot.

Maybe have the exciter in the nxt position?

Just a thought.

Steve.

Verbose!

Imaginos.

It was a struggle to read,and over the years I have read it a few times!

And every time I picked up on something new ,it's like he hid thing in all those words!

Steve.

Imaginos.

It was a struggle to read,and over the years I have read it a few times!

And every time I picked up on something new ,it's like he hid thing in all those words!

Steve.

Bernardy.

The small balsa ply panels 6x4inch 2mm,which I had been testing ,which had a good response.

Was basically just glued to the canvas panel,

The response of the canvas panel and characteristic sound was if I remember rightly ,pretty much the same as the balsa panel but with vastly extended low end.

Looking forward to the results of your tests.

Steve.

The small balsa ply panels 6x4inch 2mm,which I had been testing ,which had a good response.

Was basically just glued to the canvas panel,

The response of the canvas panel and characteristic sound was if I remember rightly ,pretty much the same as the balsa panel but with vastly extended low end.

Looking forward to the results of your tests.

Steve.

@xrk971 and @Jamu,

Thanks for the prompt xrk971

On tall panels I have found the following.

From 100Hz out to 20kHz with EQ I have found the performance to be just as good at the 'conventional' golden section or silver section ratios. Combined with a decent subwoofer you get wonderful performance for the money, in my view , having lived with ESL's for years, the sound is on par but with better rendition of instrument timbre and better attack.

Nothing controversial about that and it makes for a very elegant and WAF friendly solution.

However, and this is the controversial bit, when building a pair of tall panels I discovered that two pairs I built had a much better bass response than panels with the conventional ratios.

BUT...

This needs careful caveating, the detail is important. I have only had this additional bass result with three layer Birch ply. As Veleric has pointed out, this material is highly anisotropic- it is much stiffer in in one axis than in the other axis at 90 degrees to the first. This is probably a big factor in the performance I get from these panels. Secondly, having used a number of mathematical models to calculate the panel eigenfrequencies I find that the simpler models for a beam rather than the models used to calculate a panel to give results closer to the performance I get in the bass. The following is highly speculative and not to be relied on, but I think it possible that the tall ratio panels transition from a DML mode to something more like a vibrating beam at lower frequencies.

None of this has been proven yet! Once the lock-in has stopped in France I plan to run some experiments using various ratio panels measuring the results with REW to try to bed this down once and for all.

Having said that, other posters have reported good bass performance from XPS/EPS panels with similar tall ratios but, I am not aware of anyone doing a side by side comparison yet. It's a work in progress.

So, used with EQ with a subwoofer with an XO at circa 100-200Hz you will get terrific performance from panels with ratios 1:3.8 and 1:4. Experiment with where you place the exciter on this ratio of panel but I find the best position to be just off the centre line on the long axis and about a third of the way up from the base. Plan to do this and, if you find like me the bass goes deeper than expected, you can dial back the subwoofer performance to taste.

Pictures are of the simplest tall panels

Burnt

I'm using small (1'x2') carbon fiber with Nomex honeycomb core panels...

Dave,

Did you buy these carbon/nomex panels or make them yourself? I'd be interested to know more details about your panels.

Eric

Bernardy.

On page 193 I have posted pictures and responses of the canvas art panel.

It would be interesting to compare your results with ordinary ply,although I did coat the panel in cascamite ,which was very hard and brittle and eventually cracked up.

Steve.

On page 193 I have posted pictures and responses of the canvas art panel.

It would be interesting to compare your results with ordinary ply,although I did coat the panel in cascamite ,which was very hard and brittle and eventually cracked up.

Steve.

aagas.

The response of your panel seems pretty stable above 500hz , most of the variations happen below the 500 mark.

I have had similar results.

Instead of EQ I blend my low frequency drivers in with the panels to help fill in these dips.

This is similar to using 4 subs to fill in the room nodes .

This works very nicely for me.

Although my dips are usually in the 100hz to 300hz region.

The hf response is down 10db at about 8k but holds there up to about 15k.

Not bad really.

A little EQ could help here as long as it doesn't set anything else off?

Any chance you could do a measurement from the back or turn the panel round and take the same measurements?

For my curiosity.

Steve

The response of your panel seems pretty stable above 500hz , most of the variations happen below the 500 mark.

I have had similar results.

Instead of EQ I blend my low frequency drivers in with the panels to help fill in these dips.

This is similar to using 4 subs to fill in the room nodes .

This works very nicely for me.

Although my dips are usually in the 100hz to 300hz region.

The hf response is down 10db at about 8k but holds there up to about 15k.

Not bad really.

A little EQ could help here as long as it doesn't set anything else off?

Any chance you could do a measurement from the back or turn the panel round and take the same measurements?

For my curiosity.

Steve

Hi Steve,

I've had some trouble today with getting equalization to work at all with the Hypex FA123 amps.

I've tried setting a 10K highstep, Q = 1, 6 db and REW measures no significant difference.

I've varied the settings to Q = 2 and 12 db., with again no real REW measurable difference.

I wonder if this happens because I bridge the amps?

Pretty certain the settings uploaded as they appear when I close down and restart the amps.

I likely need to reach out to Hypex unless anyone here has any suggestions.

Something odd about this.

I've had some trouble today with getting equalization to work at all with the Hypex FA123 amps.

I've tried setting a 10K highstep, Q = 1, 6 db and REW measures no significant difference.

I've varied the settings to Q = 2 and 12 db., with again no real REW measurable difference.

I wonder if this happens because I bridge the amps?

Pretty certain the settings uploaded as they appear when I close down and restart the amps.

I likely need to reach out to Hypex unless anyone here has any suggestions.

Something odd about this.

aagas.

I would think your amps would play whatever sound you put into them.

As long as your computer is outputting it?

Can you hear a difference in the sound while playing music?

Where is the music connection to the amps?

Steve.

I would think your amps would play whatever sound you put into them.

As long as your computer is outputting it?

Can you hear a difference in the sound while playing music?

Where is the music connection to the amps?

Steve.

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker