Hi all, I have been reading the thread, and have probably forgotten more than I have remembered.

I've built approx. 1'x4'x5mm ply panels. I'd love to go thinner but they seem to start warping below this thickness. Already rounded the corners and sanded the edges. I'm planning to suspend from above on fishing line, and getting some insulation behind them if I end up mounting on a wall.

I have 4x Dayton 4ohm 24W exciters with adhesive mounting.

I've tested the exciter holding by hand and I really liked the sound. Particularly for heavy metal it sounded absolutely perfect. Bass was surprisingly decent as well, maybe since I was expecting it to be terrible based on the discussions here. I think it was comparable to many bookshelf speakers, and it hit surprisingly hard, the kind of bass you can feel impact you. Obviously acoustic music sounds good as well.

I have a few questions before I proceed with soldering the exciters up and mounting:

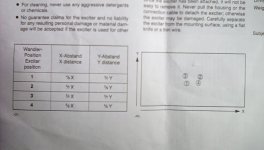

1. Lots of discussion about ratios for locating the exciters, but has there been any consensus? I've seen 0.4 x 0.4, 3/5 x 2/5, and other suggestions. Also: for location for mounting a second exciter I have not seen much discussion.

2. Do I need to treat the plywood mounting area with some glue to make a good adhesive mounting surface or will mounting straight onto the relatively smooth plywood be ok?

3. What is the best method for temporary mounting for testing? Just holding it in place doesn't allow me to back up and listen. And letting the exciter sit freely will not give the panel the full vibration.

4. Will using 2 exciters per panel in series (this is nice, giving 8 ohms resistance) give me a lot more volume than just one, or will it be just a little bit louder? (I assume it won't be doubly as loud)

5. I was thinking about some making some balsa structural struts to glue on the back (think like a piano soundboard), I wonder if this will be enough of an improvement to be worth the time.

I've built approx. 1'x4'x5mm ply panels. I'd love to go thinner but they seem to start warping below this thickness. Already rounded the corners and sanded the edges. I'm planning to suspend from above on fishing line, and getting some insulation behind them if I end up mounting on a wall.

I have 4x Dayton 4ohm 24W exciters with adhesive mounting.

I've tested the exciter holding by hand and I really liked the sound. Particularly for heavy metal it sounded absolutely perfect. Bass was surprisingly decent as well, maybe since I was expecting it to be terrible based on the discussions here. I think it was comparable to many bookshelf speakers, and it hit surprisingly hard, the kind of bass you can feel impact you. Obviously acoustic music sounds good as well.

I have a few questions before I proceed with soldering the exciters up and mounting:

1. Lots of discussion about ratios for locating the exciters, but has there been any consensus? I've seen 0.4 x 0.4, 3/5 x 2/5, and other suggestions. Also: for location for mounting a second exciter I have not seen much discussion.

2. Do I need to treat the plywood mounting area with some glue to make a good adhesive mounting surface or will mounting straight onto the relatively smooth plywood be ok?

3. What is the best method for temporary mounting for testing? Just holding it in place doesn't allow me to back up and listen. And letting the exciter sit freely will not give the panel the full vibration.

4. Will using 2 exciters per panel in series (this is nice, giving 8 ohms resistance) give me a lot more volume than just one, or will it be just a little bit louder? (I assume it won't be doubly as loud)

5. I was thinking about some making some balsa structural struts to glue on the back (think like a piano soundboard), I wonder if this will be enough of an improvement to be worth the time.

I dip into this thread every so often but today I found a company called ‘Amina Sound’ that sells ‘invisible ‘ instal DML panels.

Has this company or products been mentioned on this thread?

Has this company or products been mentioned on this thread?

OMG, what's wrong with me? (Please don't answer that, at least not in print.)

This is definitely *not* the debut I wanted to make on diyaudio.

With a third coat of embarrassment, here's the link to the article/experiment re DML bass speakers. It won't be riveting after that drumroll, but I hope you'll read it anyway.

https://web.wpi.edu/Pubs/E-project/...ucy_Zielinski_Low_Profile_Speaker_Stabile.pdf

This is definitely *not* the debut I wanted to make on diyaudio.

With a third coat of embarrassment, here's the link to the article/experiment re DML bass speakers. It won't be riveting after that drumroll, but I hope you'll read it anyway.

https://web.wpi.edu/Pubs/E-project/...ucy_Zielinski_Low_Profile_Speaker_Stabile.pdf

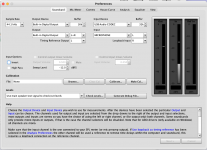

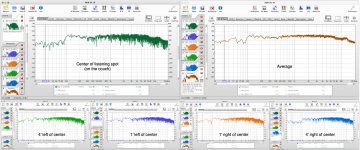

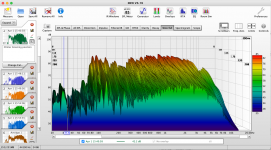

Think I've got my hardware and REW running properly.

It took some fiddling around with preferences.

Curiously, when I have the "Input" set to "MICROPHONE" i can only make measurements with the setting on "L".

I wonder if REW can only see the "Master" Hypex FA123 in this context?

I've used the Behringer ECM8000 microphone right of of the box.

Maybe it needs a correction file. Not far enough along with this to know, suggestions appreciated.

Not certain if the measurements I have attached make sense.

Thoughts and explanations appreciated.

It took some fiddling around with preferences.

Curiously, when I have the "Input" set to "MICROPHONE" i can only make measurements with the setting on "L".

I wonder if REW can only see the "Master" Hypex FA123 in this context?

I've used the Behringer ECM8000 microphone right of of the box.

Maybe it needs a correction file. Not far enough along with this to know, suggestions appreciated.

Not certain if the measurements I have attached make sense.

Thoughts and explanations appreciated.

Attachments

Yeah, I saw the prices and thought ‘where does the money get spent on’. ?

£1400.00 a pair for their top range. Just a frame a panel and some exciters does not seem to offer particularly good value unless they are amazing sounding, which is possible, but I’ll never find out. There are some for Sale on EBay at the moment. 4 x panels for £900.00

£1400.00 a pair for their top range. Just a frame a panel and some exciters does not seem to offer particularly good value unless they are amazing sounding, which is possible, but I’ll never find out. There are some for Sale on EBay at the moment. 4 x panels for £900.00

Jerryo.

4 for 900 wow ,what a bargain,now where did I leave my wallet?😱

One exciter cost me about £ 2.50 ten years ago plus £8 for a 6x4ft 25mm eps panel,which I can get 4 2x4 panels out of.

mmmmmmm on second thoughts.😀

Steve.

4 for 900 wow ,what a bargain,now where did I leave my wallet?😱

One exciter cost me about £ 2.50 ten years ago plus £8 for a 6x4ft 25mm eps panel,which I can get 4 2x4 panels out of.

mmmmmmm on second thoughts.😀

Steve.

Hey Steve,

If your evening has you up late, what do you make of the measurements I posted yesterday?

-- Andreas

If your evening has you up late, what do you make of the measurements I posted yesterday?

-- Andreas

Imaginos.

Hi.

1 the nxt patent 4/9 x3/7 works for me,I also like the more central location,you can experiment with all the choices, and make your own choice.

2. A bead of neat pva on the exciter foot should do fine on uncoated ply.

3. A roll of double sided tape should keep it stuck enough for testing,just don't expect it to still be stuck next day.

Some 1inch masking tape could be used to support the magnet end ,taped to the top of the panel.

Which I have done.

This would last longer.

4.this you can also test yourself ,I would say not very much,I was disappointed.

But I wasn't using 5mm ply.

5.You are now in the realms of guess work,will what you do improve or or make things worse? And once it's glued on its not going to come off without damaging the panel.

Personally I think 5mm is stiff enough,it is up to you how much time and effort you want to put into the panel?

Steve.

Hi.

1 the nxt patent 4/9 x3/7 works for me,I also like the more central location,you can experiment with all the choices, and make your own choice.

2. A bead of neat pva on the exciter foot should do fine on uncoated ply.

3. A roll of double sided tape should keep it stuck enough for testing,just don't expect it to still be stuck next day.

Some 1inch masking tape could be used to support the magnet end ,taped to the top of the panel.

Which I have done.

This would last longer.

4.this you can also test yourself ,I would say not very much,I was disappointed.

But I wasn't using 5mm ply.

5.You are now in the realms of guess work,will what you do improve or or make things worse? And once it's glued on its not going to come off without damaging the panel.

Personally I think 5mm is stiff enough,it is up to you how much time and effort you want to put into the panel?

Steve.

aagass

Hi.

Yes I'm still up.

Your measurements are in 20db steps ,so it is hard to see what is going on.

5db steps would be more helpful.

I'm not an expert with rew,but I think it should be smoothed as well for clarity.

Hopefully someone can give you pointers on how to set it up.

Steve.

Hi.

Yes I'm still up.

Your measurements are in 20db steps ,so it is hard to see what is going on.

5db steps would be more helpful.

I'm not an expert with rew,but I think it should be smoothed as well for clarity.

Hopefully someone can give you pointers on how to set it up.

Steve.

I have a few questions before I proceed with soldering the exciters up and mounting:

1. Lots of discussion about ratios for locating the exciters, but has there been any consensus? I've seen 0.4 x 0.4, 3/5 x 2/5, and other suggestions. Also: for location for mounting a second exciter I have not seen much discussion.

2. Do I need to treat the plywood mounting area with some glue to make a good adhesive mounting surface or will mounting straight onto the relatively smooth plywood be ok?

3. What is the best method for temporary mounting for testing? Just holding it in place doesn't allow me to back up and listen. And letting the exciter sit freely will not give the panel the full vibration.

4. Will using 2 exciters per panel in series (this is nice, giving 8 ohms resistance) give me a lot more volume than just one, or will it be just a little bit louder? (I assume it won't be doubly as loud)

5. I was thinking about some making some balsa structural struts to glue on the back (think like a piano soundboard), I wonder if this will be enough of an improvement to be worth the time.

Imaginos,

Here are my own thoughts about your questions:

1. Put the two exciters in the vicinity of the center and move them both around until you find a combination of positions that works well. Probably you can skip positions that are outside of the middle third of the panel along either axis. Ideally you would test each combination with REW.

2. You can attach directly to smooth plywood, but if you seal the area first with a coat or two of polyurethane, you may be able to get the exciter off the panel later (should you need too) without delaminating the plywood.

3. If you mount you panels horizontally for testing, you can place a small piece of foam and a weight (maybe 100 or 200 grams) on top of the exciter that and it will keep the exciter from bouncing around.

4. That's what I do. And no, it's not nearly twice as loud. Barely louder at all in fact. But it's safer for your amp (if it's only designed for 8 ohms). Usually I can get a bit flatter response with two than I can with one.

5. I don't know. Worth a try if you would enjoy doing it, even if it doesn't work.

Eric

aagas.

If you are still having problems with line one .

The behringer is for pro sound,your microphone is xlr mono with central Jack plug for line in and you are plugged into line one.

Line 2 input is inST Jack plug (probably to plug your guitar in) or line stereo.

You have gain knobs for line one and two.

Steve.

If you are still having problems with line one .

The behringer is for pro sound,your microphone is xlr mono with central Jack plug for line in and you are plugged into line one.

Line 2 input is inST Jack plug (probably to plug your guitar in) or line stereo.

You have gain knobs for line one and two.

Steve.

I was thinking of sizes like 60x40 cm, tectonic uses carbon fiber with honeycomb, I believe in aluminum, but before spending those figures I wanted to try some kind of different material but I don't know yet

Pixel1,

I am also interested to know what the Tectonic panels are made of. Where did you get the idea they were carbon fiber over aluminum honeycomb? It would be a reasonable construction of course. But I think if they use carbon fiber skins they would more likely use Nomex (polyamide) honeycomb instead of aluminum. Carbon fiber can induce galvanic corrosion in aluminum. Probably there are ways to prevent it but it's probably easier just to use something other than aluminum.

Eric

aagass

I'm not an expert with rew,but I think it should be smoothed as well for clarity.

Most people, myself included, tend to use 1/12 or 1/6 octave smoothing. Those clean up the noise without hiding too much detail.

Eric

aagas.

If you are still having problems with line one .

The behringer is for pro sound,your microphone is xlr mono with central Jack plug for line in and you are plugged into line one.

Line 2 input is inST Jack plug (probably to plug your guitar in) or line stereo.

You have gain knobs for line one and two.

Steve.

A mystery revealed.

Most people, myself included, tend to use 1/12 or 1/6 octave smoothing. Those clean up the noise without hiding too much detail.

Eric

Ah, that makes sense. I'll post some new measurements over the weekend.

Thx.

Imaginos.

This is a picture of the next patent for up to 4 exciters .

Plus patent ,if you want to trawl through all the mind numbing words,but there is a lot of good info hidden in there.

US20060159293A1 - Acoustic device

- Google Patents

This is a picture of the next patent for up to 4 exciters .

Plus patent ,if you want to trawl through all the mind numbing words,but there is a lot of good info hidden in there.

US20060159293A1 - Acoustic device

- Google Patents

Attachments

Tem3000.

That patent has a pretty narrow hump in the low end.

This patent which is sited in the last patent and with similar design with fig 8 has looked more promising to me.

Not sure if this is the idea where BMR came from?

I do toy with the idea,now and again, to do my own version of this,but it is not a priority as I have plenty of lf drive .

US3164221A - Low frequency loudspeaker system

- Google Patents

Steve.

That patent has a pretty narrow hump in the low end.

This patent which is sited in the last patent and with similar design with fig 8 has looked more promising to me.

Not sure if this is the idea where BMR came from?

I do toy with the idea,now and again, to do my own version of this,but it is not a priority as I have plenty of lf drive .

US3164221A - Low frequency loudspeaker system

- Google Patents

Steve.

Last edited:

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker