You mean like pushing and pulling the diaphragm by the generated pressure? I've never thought about that.

The cones must then breathe through 2 slots, each.

Tbh, I'm not convinced of the suitability of MEHs for hi-fi purpose (just my personal opinion), but there's a reason why Danley uses strictly conical horns.

My favorite Danley is the Jericho J1, because that one doesn't sound like a giant horn. At least not at a distance of 5-50 meters.

Tbh, I'm not convinced of the suitability of MEHs for hi-fi purpose (just my personal opinion), but there's a reason why Danley uses strictly conical horns.

My favorite Danley is the Jericho J1, because that one doesn't sound like a giant horn. At least not at a distance of 5-50 meters.

Last edited:

Ease of manufacturing?but there's a reason why Danley uses strictly conical horns.

Why?The cones must then breathe through 2 slots, each.

I admit I know very little about these, I have no experience on my own. Never felt the attraction so much that I would really try.

Last edited:

You mean like pushing and pulling the diaphragm by the generated pressure? I've never thought about that.

Some of the pressure should take the route towards the HF driver - the distribution being governed, I suppose, by the acoustical impedance exposed by each of the two possible directions.

//

Again, what's the difference between this and the typical MEH? Why do you think it's so different in this regard?

Maybe you are right but I don't see the reasoning yet. There are even coaxial compression drivers...

Maybe you are right but I don't see the reasoning yet. There are even coaxial compression drivers...

Last edited:

I always thought that the closer are the entries/ports to the HF driver the better. It's not that simple?

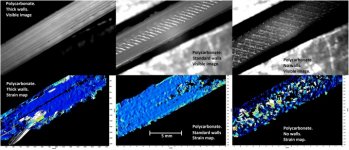

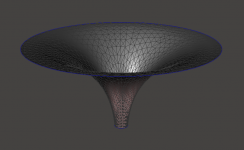

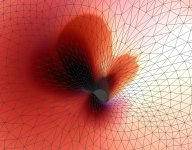

It should be possible to print the slotted throat and the initial part of the mouth with (solid) polycarbonate filament and add a mounting flange.

The rest of the mouth could be made of wood.

Have you printed with polycarbonate before, if so what was it like? I don't know anything about it's acoustic properties, but it's always impressed in everything else I've seen it used for... It's expensive as hell though!

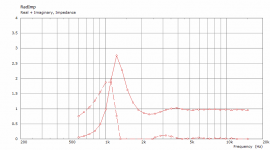

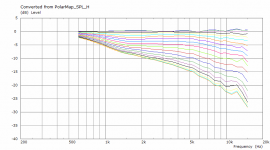

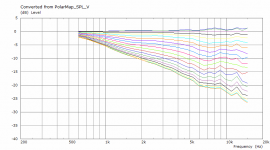

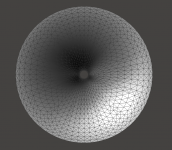

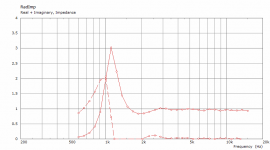

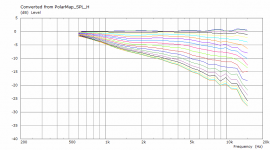

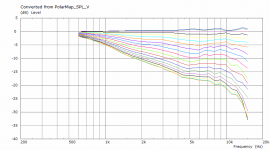

Ø36 cm is reached for 162 mm of length, slot 60 mm (the same as before), 1" throat, infinite baffle -Something slightly bigger perhaps?

Total length: 18 cm, slot length: 6 cm, mouth Ø: 36 cm.

(Well this is just a first quick try, no optimization whatsoever.)

Attachments

Last edited:

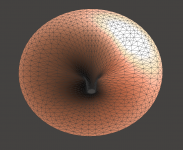

I think this would work as MEH without any issues. Only the hole area is important. And thr placement should be 1/4 wavelength at the crossover or closer.

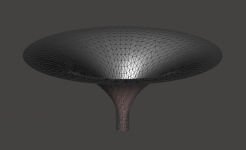

⌀330 x 162 mm, slot 80 mm:

Attachments

Last edited:

While a slot doesn't get "overloaded" by a compression driver, I think the additional pressure of 2 cones may be too much, especially given the passband (low midrange).

Have you printed with polycarbonate before, if so what was it like? I don't know anything about it's acoustic properties, but it's always impressed in everything else I've seen it used for... It's expensive as hell though!

No, my experience with 3D printing is exactly zero.

Although I have a friend who works for a 3D printer manufacturer and he suggested playing with his printer.

I believe their polycarbonate filament is available at cost price.

I think this would work as MEH without any issues. Only the hole area is important. And thr placement should be 1/4 wavelength at the crossover or closer.

and the mids should be within that 1/4 from each other as well. This kind of throat enables wider pattern than conical horn Danley uses because the opening angle is less where the mids are than the pattern.

How to evaluate that? Measure distortion with and without the cone drivers?

Can you messure pressure at the throat in the simulation? only mid playing. In real world you could measure with the driver, use it as microphone.

Tried to google up how pressure changes in pipes, no idea if it goes to horns but narrow part of narrowing pipe has less pressure since the speed increases so pressure should be less in the throat than in the mouth. How much less and does it matter, got no idea. Mouth is just atmospheric pressure? Just thinking while writing. Maybe distortion measurement is the right way.

Last edited:

I think horns work so that the high pressure/low velocity at the throat transforms into high velocity/low pressure at the mouth.

I won't simulate the mids 🙂

I won't simulate the mids 🙂

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)