linear horizontal AND vertical motion

I like Mike's project because it goes against the grain, in fact against my own grain! I don't necessarily agree with the approach but I like its experimental spirit. Maybe I am a masochist or it is my own intellectual perversity that I enjoy people having a take on things different from mine and making a case for it. Much respect from me.

One of my pet peeves about tonearms is dealing with the conflict of VTA obsession and its necessity. It would be rewarding to see an invention that can do away with it completely, alas, WITHOUT complexity. (I believe Carlo is onto something and maybe he's cooking something unpublished yet.) Just imagine an arm moving purely vertically without pivoting: a linear tonearm in its purest form, horizontally AND vertically.

Mike's project fulfill that linear motion goal and it's an encouraging direction. Unfortunately I agree with Jim about its complexity and extra contact points. But it's okay to start off with something Rube Goldberg-ish and then refine and simplify along the way in its revisions. Tweaking is fun! I look forward to a design or refinement that holds those linear motion concepts with as little number of contacts or bearings as possible. The brave new world of tonearm design might be discovered in this forum. How exciting!

I like Mike's project because it goes against the grain, in fact against my own grain! I don't necessarily agree with the approach but I like its experimental spirit. Maybe I am a masochist or it is my own intellectual perversity that I enjoy people having a take on things different from mine and making a case for it. Much respect from me.

One of my pet peeves about tonearms is dealing with the conflict of VTA obsession and its necessity. It would be rewarding to see an invention that can do away with it completely, alas, WITHOUT complexity. (I believe Carlo is onto something and maybe he's cooking something unpublished yet.) Just imagine an arm moving purely vertically without pivoting: a linear tonearm in its purest form, horizontally AND vertically.

Mike's project fulfill that linear motion goal and it's an encouraging direction. Unfortunately I agree with Jim about its complexity and extra contact points. But it's okay to start off with something Rube Goldberg-ish and then refine and simplify along the way in its revisions. Tweaking is fun! I look forward to a design or refinement that holds those linear motion concepts with as little number of contacts or bearings as possible. The brave new world of tonearm design might be discovered in this forum. How exciting!

Hello Mike. You've done a great job and made a tonarm that plays better than any turning tonearm. Don't look for what this tonearm doesn't have, listen to the music and enjoy it.

If you’re bored, you can work on how it looks.

Hey Edouard, thanks so much for feedback, i am enjoying the music and thinking about progress as well..............!

Hey DD, thanks for coming on board, apart from anything else i like the open minded enthusiasm of your reply. i don't know if what i am doing is good, bad or average but i am enjoying finding out and greatly value all inputs.I like Mike's project because it goes against the grain, in fact against my own grain! I don't necessarily agree with the approach but I like its experimental spirit. Maybe I am a masochist or it is my own intellectual perversity that I enjoy people having a take on things different from mine and making a case for it. Much respect from me.

!

I believe you, Carlo is working on something already partly published and i like my true linear approach, but i don't really know what i am doing!!One of my pet peeves about tonearms is dealing with the conflict of VTA obsession and its necessity. It would be rewarding to see an invention that can do away with it completely, alas, WITHOUT complexity. (I believe Carlo is onto something and maybe he's cooking something unpublished yet.) Just imagine an arm moving purely vertically without pivoting: a linear tonearm in its purest form, horizontally AND vertically.

The brave new world of tonearm design might be discovered in this forum. How exciting!

That might be a significant hope, but you never know, the more contributions the better!!The brave new world of tonearm design might be discovered in this forum. How exciting!

What’s the number of mikes post for his diy arm ?

Lets just say he is a prolific writer...

And enjoy the ride like I have been doing.

I know, I know, i get all over-enthusiastic and write too much. It comes from lock down, its coming up to a year now that little meaningful normal outside direct contact has been possible, so cabin fever as well. When the golf course re-opens i will post less i promise. just search back on the posts in the last months and i think the whole journey is there, if it helps i can post the current sit-rep as a (short, i promise!) summary........?

M

What’s the number of mikes post for his diy arm ?

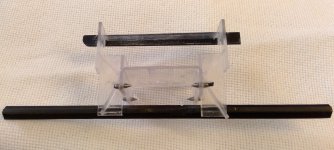

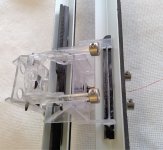

Hi Carlthess, i attach hereto pics of the current state with apologies for poor workmanship, its been "adjusted" many many times. It is also made with hand tools only, saw, file, drill.

Some white background aids visibility

Six pictures

1. Rails and balls

2. Cart on rails

3. Cart with pen tip pivots mounted

4. Top parallelogram plate that fits between pen tips

5. Paralellogram on cart

6. Other view

Hope this updates all

M

Attachments

-

WIN_20210303_10_35_18_Pro.jpg583.9 KB · Views: 263

WIN_20210303_10_35_18_Pro.jpg583.9 KB · Views: 263 -

WIN_20210303_10_35_47_Pro.jpg477.7 KB · Views: 268

WIN_20210303_10_35_47_Pro.jpg477.7 KB · Views: 268 -

WIN_20210303_10_37_19_Pro.jpg686.3 KB · Views: 255

WIN_20210303_10_37_19_Pro.jpg686.3 KB · Views: 255 -

WIN_20210303_10_37_58_Pro.jpg334.6 KB · Views: 249

WIN_20210303_10_37_58_Pro.jpg334.6 KB · Views: 249 -

WIN_20210303_10_42_24_Pro.jpg798.9 KB · Views: 256

WIN_20210303_10_42_24_Pro.jpg798.9 KB · Views: 256 -

WIN_20210303_10_41_17_Pro.jpg532.2 KB · Views: 208

WIN_20210303_10_41_17_Pro.jpg532.2 KB · Views: 208

What’s the number of mikes post for his diy arm ?

Let's say that if some of the many experts of this thread would solve just one of the questions posed by this truly innovative arm, Mike could be less prolific in subjecting them to our inattention.

carlo

Let's say that if some of the many experts of this thread would solve just one of the questions posed by this truly innovative arm, Mike could be less prolific in subjecting them to our inattention.

carlo

Koldby, you were thinking a sort of difficult to understand impressionistic sort of piece of art i imagine, but i take it as a great complement thankyou!

Carlo, that's an interesting approach, anyone got some suggestions item by item for me please?

BTW i have had quite a few good answers on the route to here, many thanks for those, so if there are good inputs now i would like to learn and implement what i can.

As DD says it has the base of a true linear/linear solution and its playing nice music so well worth further effort!

M

Carlo, that's an interesting approach, anyone got some suggestions item by item for me please?

BTW i have had quite a few good answers on the route to here, many thanks for those, so if there are good inputs now i would like to learn and implement what i can.

As DD says it has the base of a true linear/linear solution and its playing nice music so well worth further effort!

M

Hi Mike,

First, usually, a heavy carriage does sound better. But you need to think about other factors as well, such as friction, resonant frequency, and compliance of cartridge. If the friction is zero, the carriage should be as heavy as the resonant frequency and the compliance of the cartridge allow.

This thread is long. I have confused with your previous version of the arm. Now, I saw the latest version of the arm. I have to say it is a very clever design. You have put your mind and passion into the arm. I have been enjoying the process as well. Although the arm is not perfect, I would say the ideas are very creative. Kudos to you and carlo!

Jim

First, usually, a heavy carriage does sound better. But you need to think about other factors as well, such as friction, resonant frequency, and compliance of cartridge. If the friction is zero, the carriage should be as heavy as the resonant frequency and the compliance of the cartridge allow.

This thread is long. I have confused with your previous version of the arm. Now, I saw the latest version of the arm. I have to say it is a very clever design. You have put your mind and passion into the arm. I have been enjoying the process as well. Although the arm is not perfect, I would say the ideas are very creative. Kudos to you and carlo!

Jim

Hi Carlthess, i attach hereto pics of the current state with apologies for poor workmanship, its been "adjusted" many many times. It is also made with hand tools only, saw, file, drill.

Some white background aids visibility

Six pictures

1. Rails and balls

2. Cart on rails

3. Cart with pen tip pivots mounted

4. Top parallelogram plate that fits between pen tips

5. Paralellogram on cart

6. Other view

Hope this updates all

M

That’s some great handy work there. Wish you where here in Florida. I’d have every tool at hand for you

Jim, i write too much, i promise to be more brief if i can!Hi Mike,

First, usually, a heavy carriage does sound better. But you need to think about other factors as well, such as friction, resonant frequency, and compliance of cartridge. If the friction is zero, the carriage should be as heavy as the resonant frequency and the compliance of the cartridge allow.

This thread is long. I have confused with your previous version of the arm. Now, I saw the latest version of the arm. I have to say it is a very clever design. You have put your mind and passion into the arm. I have been enjoying the process as well. Although the arm is not perfect, I would say the ideas are very creative. Kudos to you and carlo!

Jim

Thanks for your thoughts and comments above, and also to other recent respondees. I am pleased it raises interest and that some of you like parts of it.

How about you all (Jim, Carlthess, DD, Carlo, Koldby, Ed, Warrjon etc to name a few in no particular order and apologies if i have missed anyone out) team up to help me make improvements as my virtual design team on this thread? - respond if you wish, not if you don't?

Two topics to start with;

Resonant frequency,

1. how much does it matter and why,

2. is it likely that this configuration compares in any way to a conventional PTA in terms of analysis

3. Maybe there are a series of RFs in various planes in different parts

4. How might i measure it/them

5. What to do about it/them

Friction.

The current configuration has quite low friction. It will only occasionally stick after re-assembly but seems to settle after a few sides and will only stick if i inadvertently dump dirt in the rails. However i would like it reduced and have more tolerance. This is ceramic 5mm balls on anodised aluminium surfaces

1. How can i reduce friction most easily and gain tolerance

2. has anyone tried teflon self adhesve tape on the rails?

BTW, one of my aims is to build with inexpensive parts by hand, depending on what you buy or have there is very little material cost involved here.

Any other areas anyone thinks should take priority?

Best to all

Mike

That’s some great handy work there. Wish you where here in Florida. I’d have every tool at hand for you

Its a pity i am not, a kind thought thanks, what do you build?

Mike

2. has anyone tried teflon self adhesive tape on the rails?

Hello Mike56,

I would stay away from Teflon tape. Teflon tape would be helpful if the friction you are encountering would be of the "sliding" kind. As you know, you are dealing with "rolling" friction, where the balls would micro indent any soft surface such as tape. The balls would constantly try to climb out of those micro indentations.

Anodized aluminum is a good way to go if the tool marks on the surface of the aluminum rail were oriented parallel to the direction of travel of the carriage, prior to anodizing. In the US, machinists refer to that as "lay"

Sincerely,

Ralf

Thanks Ralf, great to have your input, i have anodised aluminium at the moment and with the marks going longitudinal with the rail. it is already quite good, i am just seeking better! - i have wondered about light polishing but worry about going through the coating, at the moment all i have done is clean thoroughly.Hello Mike56,

I would stay away from Teflon tape. Teflon tape would be helpful if the friction you are encountering would be of the "sliding" kind. As you know, you are dealing with "rolling" friction, where the balls would micro indent any soft surface such as tape. The balls would constantly try to climb out of those micro indentations.

Anodized aluminum is a good way to go if the tool marks on the surface of the aluminum rail were oriented parallel to the direction of travel of the carriage, prior to anodizing. In the US, machinists refer to that as "lay"

Sincerely,

Ralf

All input gratefully recieved

thanks

Mike

Hi Mike,

To test arm / cart resonance, HFN test LP has resonant frequency test tracks on side B. If you don't have that LP then pink noise will also identify arm / cart resonance.

The test tracks are easy as you can hear it. Pink noise you would need to use your spectrum analyser.

To test arm / cart resonance, HFN test LP has resonant frequency test tracks on side B. If you don't have that LP then pink noise will also identify arm / cart resonance.

The test tracks are easy as you can hear it. Pink noise you would need to use your spectrum analyser.

It's actually not friction you need to be low it's rolling resistance more importantly stiction.

If you had no friction then the balls would slide on the rail, which you definitely do not want. Stiction is the resistance to commence moving and is critically important in a passive LTA, you want this as low as possible. Increasing the diameter of the balls will lower torque required to commence movement.

If you had no friction then the balls would slide on the rail, which you definitely do not want. Stiction is the resistance to commence moving and is critically important in a passive LTA, you want this as low as possible. Increasing the diameter of the balls will lower torque required to commence movement.

Hi Mike,

To test arm / cart resonance, HFN test LP has resonant frequency test tracks on side B. If you don't have that LP then pink noise will also identify arm / cart resonance.

The test tracks are easy as you can hear it. Pink noise you would need to use your spectrum analyser.

many thanks Warren, i have played the 23 to 6 Hz track several times and also watched the output at those frequencies on the spectrum analyser. at the start you can just hear the 23 Hz rumbling away and then that goes sub audible, but i hear and see nothing else. So looking at the spectrum analyser zoomed as close as it will go i see the tone and it simply sits there as a peak and gradually reduces in frequency through the sweep, level reduces slightly and consistently through the sweep, but i see no sudden peaks of resonance in that frequency area. As i write this i wonder if i should be playing those frequencies but looking elsewhere for resonant harmonics?

Thanks as always

Mike

It's actually not friction you need to be low it's rolling resistance more importantly stiction.

If you had no friction then the balls would slide on the rail, which you definitely do not want. Stiction is the resistance to commence moving and is critically important in a passive LTA, you want this as low as possible. Increasing the diameter of the balls will lower torque required to commence movement.

Understand thanks. Useful again thanks Warren. i have 5mm at the moment, do you have any experience to suggest the best size to use please? i am also considering what might be a better surface than simple natural anodised aluminium for the rails, all budget materials of course! i guess in some cases surface roughness will increase both stiction and friction and one assumes surface smoothness is therefore important and i don't feel the arrangement i have ever has a tendency for the balls to slide, the contact is constant and that seems unlikely so if low stiction comes with low friction i feel its worth a try, Mike

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm