Good to see lenco and TA here, this is my third lenco and linear tonearm.

Thinking about the LC mkiii now hopefully to beat the rs-lab.

Great to see you on the thread and to see what you are doing.

We look forward to seeing more as you move on.

I would reach out to Carlo and see what feedback he gives you as well.

He has done so much work and development he has surely forgotten more than i know and can guide you if you tell him what youre aiming for.

My experience is short and limited but theres great feedback to be had and it gives you the opportunity to check things through carefully rather than rely on intuition or just one experience.

I am just starting on the Lenco and will try to do that like the arm, work rather than cost!

Interesting article and many thanks Jonathon for those various thoughts. i am going to read quite a lot before i start this one!This is an excellent article which might help in choosing materials if you haven’t seen it already.

https://qualia.webs.com/plinthbuilding.htm

A very similar thought process to mine, but i am much more stingy than you!My mindset was if you could build a very good deck for almost no money, is it possible to build a massively high performing deck with a relatively modest outlay in comparison with spending £10,000 upwards.

Of course that doesnt mean it can be done, but i will have a go.

I hope to test out the theory/guesswork on here so look forward to your feedback!

It’s all a journey and fun discovering. If you haven’t discovered it yet lenco heaven is a great resource, there is also a fb group which is extremely good.

Jonathan

I agree with that, great fun, even making mistakes as often as i do!

Mike

Good to see lenco and TA here, this is my third lenco and linear tonearm.

Thinking about the LC mkiii now hopefully to beat the rs-lab.

Looks great. Is that a Diy ptp type thing or a real one? Have you split the plinth? I’ve always been intrigued by that rs arm and never heard one. How does it sound in comparison with the linear one? Last question. What bearings do you use?

Looks great. Is that a Diy ptp type thing or a real one? Have you split the plinth? I’ve always been intrigued by that rs arm and never heard one. How does it sound in comparison with the linear one? Last question. What bearings do you use?

That's a diy ptp on 4mm alu plate.

The motor is serviced, and on a separate island cut out from the main plinth.

RS-A1 is more organic and fluent even though can hardly get balanced.

I am using the SPH long bearing.

Thanks. If I were to build another one I’d do a Diy ptp as well.

Interesting re the arm. They are quite a rare thing.

Bw

Interesting re the arm. They are quite a rare thing.

Bw

@jw67,

Bearings are a good point. My first LTA used 623's and found the arm miss tracked with the Stanton 881s, I made a lets call it a tyre from 316 stainless to increase the OD of the wheel to 19mm even though it added mass it stopped the miss tracking once I got the wiring sorted.

The larger the diameter of the wheel the lower the starting torque required to get the carriage moving.

Magnet wire works well I buy mine from RS Components as it not much more expensive than eBay.

I also like the way your LTA is mounted both sides which add stability. I measured the Pyrex rods and found them to vary in thickness and they were not concentric.

You can buy HSS or linear rails in 6mm these are far better than the glass and for the price IMO better than carbide. The carbide rods I bought were expensive and not straight.

Bearings are a good point. My first LTA used 623's and found the arm miss tracked with the Stanton 881s, I made a lets call it a tyre from 316 stainless to increase the OD of the wheel to 19mm even though it added mass it stopped the miss tracking once I got the wiring sorted.

The larger the diameter of the wheel the lower the starting torque required to get the carriage moving.

Magnet wire works well I buy mine from RS Components as it not much more expensive than eBay.

I also like the way your LTA is mounted both sides which add stability. I measured the Pyrex rods and found them to vary in thickness and they were not concentric.

You can buy HSS or linear rails in 6mm these are far better than the glass and for the price IMO better than carbide. The carbide rods I bought were expensive and not straight.

Very interesting about the bearings. I think earlier in the thread niffy had mentioned inside 3mm outside 10mm and a width of 4mm. I am going to order some of those but I was worried about the width with the 2 6mm rods. A company sent me some 5mm width ones by mistake and they had nowhere near enough the right vertical movement, maybe 4mm is ok.

I spoke to a company that produced quartz glass rods yesterday . The MD asked me to call him as he was interested in the project and talked me through the different types of glass...none are round and all have a deviation(maybe not synthetic quartz but prohibitively expensive) The only way to get it completely straight is to grind it but then you have to flame glaze it to get it smooth and then you’re back to not straight. He picked me out 4 rods with a 0.2mm deviation and sent them free. I’ll see how they go but they feel a lot better than the current rods.

I haven’t come across hss linear rails, I’ll definitely look into that thanks. I had thought of carbide but your experience rules that one out.

The magnet wire came today, it is thin. They apparently sell it to audio companies to make transformers, chokes, speakers etc. 99.99 we shall see. It looks like the right thickness though and it sounds like the quality is ok. What a cheap way to get Tonearm wire..bargain.

I spoke to a company that produced quartz glass rods yesterday . The MD asked me to call him as he was interested in the project and talked me through the different types of glass...none are round and all have a deviation(maybe not synthetic quartz but prohibitively expensive) The only way to get it completely straight is to grind it but then you have to flame glaze it to get it smooth and then you’re back to not straight. He picked me out 4 rods with a 0.2mm deviation and sent them free. I’ll see how they go but they feel a lot better than the current rods.

I haven’t come across hss linear rails, I’ll definitely look into that thanks. I had thought of carbide but your experience rules that one out.

The magnet wire came today, it is thin. They apparently sell it to audio companies to make transformers, chokes, speakers etc. 99.99 we shall see. It looks like the right thickness though and it sounds like the quality is ok. What a cheap way to get Tonearm wire..bargain.

Linear rail - I bough these to try them, they have not arrived yet but they do spec for straightness.

Dia 4mm-22mm Cylinder Rail Linear Shaft Smooth Rod Optical Axis Various Lengths | eBay

6mm rail with 4mm wide bearings are correct according to Niffy's research. This is what I used for my first rail. Current rail uses pin bearings 4mm carbide rods and 2mm wheels.

Dia 4mm-22mm Cylinder Rail Linear Shaft Smooth Rod Optical Axis Various Lengths | eBay

6mm rail with 4mm wide bearings are correct according to Niffy's research. This is what I used for my first rail. Current rail uses pin bearings 4mm carbide rods and 2mm wheels.

The magnet wire came today, it is thin. They apparently sell it to audio companies to make transformers, chokes, speakers etc. 99.99 we shall see. It looks like the right thickness though and it sounds like the quality is ok. What a cheap way to get Tonearm wire..bargain.

Did you find niffy's "instructions" ok?

I solder it around 400c to make sur that the enamel burns off at the joint, i soldered up one set at 370 and got no connection, very disappointing .............

Yes I did find his instructions, well unless there is a second set later on. It didn’t have instructions on temperature settings though. That’s very helpful, I usually solder at 375 so I’ll up it to 400, thanks.

On a quest to improve the performance of my LTA I have been very fortunate to have extremely helpful and very patient advice from a number of knowledgeable folks who follow and write on this thread, enormous thanks to all of you for that.

As a result, i took what was for me a plunge into the unknown and started measuring digitally the output of my TT/TA set up and, with much help, by studying the results critically I have made iterative changes and consequently I have substantially improved its performance both in the measured results and audibly.

I hope some will find it interesting and useful and perhaps give me some feedback.

After listening to those with greater experience and knowledge I consider my TA has a sound technical geometry for a start point. It is a rigid radial rail with a vertical movement mechanism running on it that allows the cartridge to always stay in constant orientation with respect to the groove with fairly constant VTF in warps and little adverse load on the stylus from friction, levers and loads of any type. This should give it a good chance to allow the cartridge to do its job freely and to sound good. I have posted pictures of it on this thread from time to time.

I am listening to the results as I type this up, its sounding good and from the start point it now has notable increases in detail and precision across the frequency range and in separation of individual parts (voice or instruments). Bass is tuneful and background noise is low as others have found with their LTAs.

I did not have a soundcard so i got a Behringer 222 ADC and fed this into the computer to view the spectrum in VA (visual analyser, a free multi-instrument download) so for extraordinarily little expenditure i got some basic tools to help with the developments.

Make no mistake i do not know much about this area but i have learnt a little from the kind advice i have been given.

Please forgive the many areas of poor practice that i am sure more knowledgeable people will spot.

Following this sound advice i explored the tools first to get a grasp of what i was looking at and then focussed on the spectrum analyser view of the output from the 1000Hz test tone from my record.

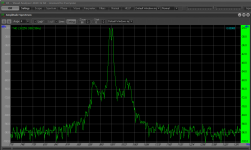

It started out with some large sidebands as you can see in the first image SS 86.

With experimentation and help i found that stiffening up all the cartridge carrier area made a massive difference and other areas followed.

I always changed one thing at a time and measured again so that i could go back to square one more readily and could identify what made the difference.

Sometimes i went backwards and as time went on not surprisingly there were some diminishing returns.

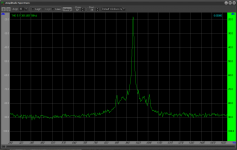

Eventually i reached the point where it measured as in SS 171.

The sidebands were just about 36db below the peak when i started. After the various modifications they are at about 58db down and less pronounced.

After 30 or 40 experiments and changes i feel i have done something about everything that might have micro-rattled or vibrated in any way.

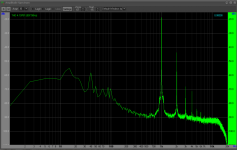

I am still left with something one can see in the wide spectrum of SS 170, it’s a peak at 40Hz and whilst reduced by work on the cue lever and cartridge wiring support its not solved yet.

It would be interesting to hear the experience, advice, and comments that others might have.

Mike

As a result, i took what was for me a plunge into the unknown and started measuring digitally the output of my TT/TA set up and, with much help, by studying the results critically I have made iterative changes and consequently I have substantially improved its performance both in the measured results and audibly.

I hope some will find it interesting and useful and perhaps give me some feedback.

After listening to those with greater experience and knowledge I consider my TA has a sound technical geometry for a start point. It is a rigid radial rail with a vertical movement mechanism running on it that allows the cartridge to always stay in constant orientation with respect to the groove with fairly constant VTF in warps and little adverse load on the stylus from friction, levers and loads of any type. This should give it a good chance to allow the cartridge to do its job freely and to sound good. I have posted pictures of it on this thread from time to time.

I am listening to the results as I type this up, its sounding good and from the start point it now has notable increases in detail and precision across the frequency range and in separation of individual parts (voice or instruments). Bass is tuneful and background noise is low as others have found with their LTAs.

I did not have a soundcard so i got a Behringer 222 ADC and fed this into the computer to view the spectrum in VA (visual analyser, a free multi-instrument download) so for extraordinarily little expenditure i got some basic tools to help with the developments.

Make no mistake i do not know much about this area but i have learnt a little from the kind advice i have been given.

Please forgive the many areas of poor practice that i am sure more knowledgeable people will spot.

Following this sound advice i explored the tools first to get a grasp of what i was looking at and then focussed on the spectrum analyser view of the output from the 1000Hz test tone from my record.

It started out with some large sidebands as you can see in the first image SS 86.

With experimentation and help i found that stiffening up all the cartridge carrier area made a massive difference and other areas followed.

I always changed one thing at a time and measured again so that i could go back to square one more readily and could identify what made the difference.

Sometimes i went backwards and as time went on not surprisingly there were some diminishing returns.

Eventually i reached the point where it measured as in SS 171.

The sidebands were just about 36db below the peak when i started. After the various modifications they are at about 58db down and less pronounced.

After 30 or 40 experiments and changes i feel i have done something about everything that might have micro-rattled or vibrated in any way.

I am still left with something one can see in the wide spectrum of SS 170, it’s a peak at 40Hz and whilst reduced by work on the cue lever and cartridge wiring support its not solved yet.

It would be interesting to hear the experience, advice, and comments that others might have.

Mike

Attachments

It puzzles me a bit that no one is reacting to this.

Mikes TA is unique and these measurements are important to finetune the clever design even more. But perhaps this hole thread is stone dead?

Mikes TA is unique and these measurements are important to finetune the clever design even more. But perhaps this hole thread is stone dead?

My guess is after Mike describes that it is changing when arranging the wires, that it is a fundamental resonance. I would try to add some mass to the horizontal moving parts and see if it changes the frequency. After that I would do the same with the vertical moving parts and watch the result.

Interesting thoughts Karsten, i did those experiments just now and added them to my record of experiments. its 26 pages now and as a pdf too big to load on here at 7Mb, any one know how to do that.My guess is after Mike describes that it is changing when arranging the wires, that it is a fundamental resonance. I would try to add some mass to the horizontal moving parts and see if it changes the frequency. After that I would do the same with the vertical moving parts and watch the result.

Meanwhile here attached are just the last few pages that show the RESULT!

M

Attachments

Have you tried changing platter speed? If that 40Hz moves when you change from 33.33 to 45rpm, it'll indicated platter, bearing, motor.. not necessarily your arm.

Have you tried changing platter speed? If that 40Hz moves when you change from 33.33 to 45rpm, it'll indicated platter, bearing, motor.. not necessarily your arm.

Interesting thought Soundblaster, here attached a paper showing thge sequence at 45rpm. if its an effect from the disc through the cartridge surely also that frequency will change?

many thanks for your input, some of those changed in different ways, i am not yet sure how to interpret?

M

Attachments

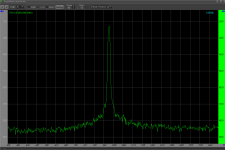

I have kept on working on experiments with the arm and find this measuring technique very useful indeed, it saves trying to make purely subjective judgements, here below is the latest measurement, the sidebands are very much reduced, but i am still chasing down that 40hz, although reduced its not gone away.......

However i feel this sounds pretty good now, the difficulty is knowing perhaps how much more is possible, anyone got any thoughts on that please?

Mike

However i feel this sounds pretty good now, the difficulty is knowing perhaps how much more is possible, anyone got any thoughts on that please?

Mike

Attachments

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm