1/4" is only going to be there for looks, due to its size.

You can have a functional roundover if you find the right value of L1. This 2.5-way crossing arrangement is the easiest to work with for tuning the baffle step, even perhaps without measurement.

Correct. Make it round part small and it will be fine. Everybody comments that the tonal balance seems just right, so losing some lower mids could upset that balance.

I hope to have new cabinets made this year and they will be rounded. I think satin (not gloss) ruby colour. They are in the South-West of Sydney and will be willing to make them for others as long as the same CNC files are used.

As for adjusting L1, you could make L1 down to 3mH and no less.

Thanks for all the great responses - I have nailed down where to source all the parts except the 90mm ID PVC tubes in the US. The only suitable candidate I can find is this: CANTEX Mfr#: 6141630 3" PVC Conduit Coupling 3-7/8" (98.425mm) long, 3.5" (88.9mm) ID X 4" (101.6mm) OD with a stopper ring in the middle. They are available locally in any HD stores for $2.70 each. I assume I will need to cut down that stopper with a utility blade somehow. Would these couplings work OK for the ports (or are there any other ideas except from buying the metric PVC tubes internationally)? 😉

I took 2 3" pvc couplings, hogged ouy the stops in the center and glued together, than cutting to length.. i used the porth length calculator available in this thread somewhere, and added 1/4" for good measure (i also fabbed another with 1/2" to be safe)

Attachments

I've found a couple port options from PE. One is 98MM ID and 111 L (which I can cut down). The other is 84 ID and 84 L. Can someone put those numbers into a port calculator (I can't seem to get it figured out) and tell me which one would work the best?

Here's another option for the port: 2pcs Subwoofer Port Tube Bass Vent For 12"/15"/18" Speaker DIY Repair 110x200mm | eBay

Regards.

Regards.

For some reason I've found imperial sizes sold here. Therefore I have to check as I don't always know what I'm going to get.

I don't see the limitation.As for adjusting L1, you could make L1 down to 3mH and no less.

I don't see the limitation.

Limitation = turning it into a 2 way with 2.5 way layout and inevitable vertical lobing problems (narrowing vertical window). Also gain in midrange setting imbalance with treble. It's not just about BSC? Unless I've completely missed your point

I can see the concerns. It's a complex enough situation and I saw that a conclusion had been drawn.

Scott, that Ebay option for the flared port tube does look good. Is this what you used in your build? If so, to what length did you cut it down? I assume because of the flare at one end, the total length would be 100mm + some portion of the flare length (may be ~1/2 of the flare length). I know that one can measure the actual tuning frequency and adjust the port, but wanted to know if you already have done the work. 🙂

Aa007:

Yup, we used that one. We started at 80mm and, as I recall, we ended cutting the port length down to 75mm. YMMV.

Regards,

Scott

Yup, we used that one. We started at 80mm and, as I recall, we ended cutting the port length down to 75mm. YMMV.

Regards,

Scott

So I have a decision to make. I've had my bamboo boards for almost a year. When I ordered them they were listed at 285mm wide and the plan was just to use that dimension for the width without having to rip something down. Turns out they are 300mm wide. Recommend baffle width is 280mm.

They are perfectly square factory cuts and I don't think I can rip them perfect which is important because there's no way to use filler for imperfections. I thought at 285 mm I'd be ok but at 300mm I think I risk a wonky outcome. Xovers are all built and ready to go.

I think I know the answer but what's the general consensus if I leave them at 300mm vs. cutting down to 280mm? Is there a solution like roundovers or bevels or should I just take a chance and rip them down?

They are perfectly square factory cuts and I don't think I can rip them perfect which is important because there's no way to use filler for imperfections. I thought at 285 mm I'd be ok but at 300mm I think I risk a wonky outcome. Xovers are all built and ready to go.

I think I know the answer but what's the general consensus if I leave them at 300mm vs. cutting down to 280mm? Is there a solution like roundovers or bevels or should I just take a chance and rip them down?

And who's winning?

Who won? 😀

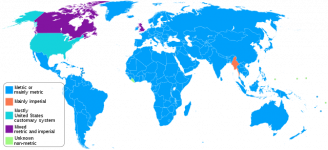

I am glad that Australia went metric 1966 (currency) and 1974 (full metric). About the same time New Zealand did. The rest of the Anglophile world did not go fully metric. The US is a funny mix of the two and did not commit. Canada did commit to a greater degree, but not totally. From an engineering point of view, metric is a no-brainer.

So Australia and New Zealand stand out. English speaking but went full metric. And pretty much the rest of the world did. Oh, I forgot India, they did too. Just watch how much big corporations are chasing low labour costs and that India will be the new China... it is already starting, for good or for bad. Most of the COVID19 vaccines are going to be made there by the end of this year!

Funny thing is I never needed metric until I started working my way through the Elsinores. I'm finding the conversions are getting easier in my mind but still have to think in imperial to gauge sizes.

Yes...cheap labor is the cheese for the big corps....

Yes...cheap labor is the cheese for the big corps....

So I have a decision to make. I've had my bamboo boards for almost a year. When I ordered them they were listed at 285mm wide and the plan was just to use that dimension for the width without having to rip something down. Turns out they are 300mm wide. Recommend baffle width is 280mm.

They are perfectly square factory cuts and I don't think I can rip them perfect which is important because there's no way to use filler for imperfections. I thought at 285 mm I'd be ok but at 300mm I think I risk a wonky outcome. Xovers are all built and ready to go.

I think I know the answer but what's the general consensus if I leave them at 300mm vs. cutting down to 280mm? Is there a solution like roundovers or bevels or should I just take a chance and rip them down?

Surely there's a cabinet , or millwork, shop somewhere in your area who, for a fee, would cut those down on one of their big, accurate, saws?

So I have a decision to make. I've had my bamboo boards for almost a year. When I ordered them they were listed at 285mm wide and the plan was just to use that dimension for the width without having to rip something down. Turns out they are 300mm wide. Recommend baffle width is 280mm.

They are perfectly square factory cuts and I don't think I can rip them perfect which is important because there's no way to use filler for imperfections. I thought at 285 mm I'd be ok but at 300mm I think I risk a wonky outcome. Xovers are all built and ready to go.

I think I know the answer but what's the general consensus if I leave them at 300mm vs. cutting down to 280mm? Is there a solution like roundovers or bevels or should I just take a chance and rip them down?

Flush trim router bit to trim the overhanging edge(s)?

That's 10mm (3/8") per side to trim .... that's a lot. You'd need a good bit and patience to take several passes.

SRMcGee:

Just to clarify, 75mm cardboard tube length did not include the plastic flare length, correct? I think my build will be quite similar to yours, as I like your suggestions for the internal damping material(s), 20mH crossover coil and now the port tube. Appreciate all the recommendations, Scott!

Just to clarify, 75mm cardboard tube length did not include the plastic flare length, correct? I think my build will be quite similar to yours, as I like your suggestions for the internal damping material(s), 20mH crossover coil and now the port tube. Appreciate all the recommendations, Scott!

- Home

- Loudspeakers

- Multi-Way

- The "Elsinore Project" Thread