Newbie question:

Would it be possible to add volume control to the xlr input circuit? I am building one and i would really need it. Even better with both channels separately.

What is the input impedance of the amp?

Would it be possible to add volume control to the xlr input circuit? I am building one and i would really need it. Even better with both channels separately.

What is the input impedance of the amp?

I dont want another preamp

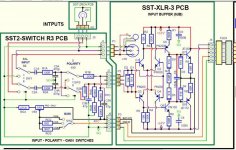

I was thinking of modifying the existing input circuit above with a potentiometer

I was thinking of modifying the existing input circuit above with a potentiometer

Just sticking a potentiometer in front of the power amp will work, but its a sub optimal solution. Better to read the article that amplitude referenced and build a simple preamp.

The article describes how balanced volume control is done, that why I uploaded it, I use elliot sound alot, I like the projects and the descriptions, perfect for hobbyist like me.

Newbie question:

Would it be possible to add volume control to the xlr input circuit? I am building one and i would really need it. Even better with both channels separately.

What is the input impedance of the amp?

10-30 кОм tested on the input module, normally.

Bryston 3B SST clone

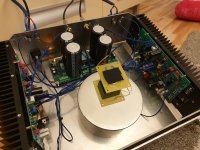

Do not want to hijack this thread, but I just wanted to show you this 3B sst clone that I just finished and tested, only in a preliminary box/assembly.

Same aliexpress board supplier as the 4B, very high quality PCBs.

Running it at +/- 49V, 300mA bias / channel, all transistors matched, PN100A/PN200A input stage, 300VA transformer that I had laying around, 4x 20 000uf filter caps.

I increased the gain a little, also changed the input filter/impedance to a more normal one, thus only requiring a 2uF input cap instead of the 10uf electrolytic one. I will later change them to Jantzen Alumen Z-Caps.

Now to the sound, really good without any burn in, no hum/hiss, great dynamics + midrange. Also I feel that the amp has very good control over the bass.

I will post more pictures when I have installed the amp in the final case.

Cheers

Paul

Do not want to hijack this thread, but I just wanted to show you this 3B sst clone that I just finished and tested, only in a preliminary box/assembly.

Same aliexpress board supplier as the 4B, very high quality PCBs.

Running it at +/- 49V, 300mA bias / channel, all transistors matched, PN100A/PN200A input stage, 300VA transformer that I had laying around, 4x 20 000uf filter caps.

I increased the gain a little, also changed the input filter/impedance to a more normal one, thus only requiring a 2uF input cap instead of the 10uf electrolytic one. I will later change them to Jantzen Alumen Z-Caps.

Now to the sound, really good without any burn in, no hum/hiss, great dynamics + midrange. Also I feel that the amp has very good control over the bass.

I will post more pictures when I have installed the amp in the final case.

Cheers

Paul

Attachments

Last edited:

Congratulations.....very nice job .....please keep posting your progress.......Do not want to hijack this thread, but I just wanted to show you this 3B sst clone that I just finished and tested, only in a preliminary box/assembly.

Same aliexpress board supplier as the 4B, very high quality PCBs.

Running it at +/- 49V, 300mA bias / channel, all transistors matched, PN100A/PN200A input stage, 300VA transformer that I had laying around, 4x 20 000uf filter caps.

I increased the gain a little, also changed the input filter/impedance to a more normal one, thus only requiring a 2uF input cap instead of the 10uf electrolytic one. I will later change them to Jantzen Alumen Z-Caps.

Now to the sound, really good without any burn in, no hum/hiss, great dynamics + midrange. Also I feel that the amp has very good control over the bass.

I will post more pictures when I have installed the amp in the final case.

Cheers

Paul

Hi Chalky. Just to confirm that appart from your new input board, the amp board itself has no mods to do, that I can use the specified schematic parts, no need to replace transistor model number? Thanks

SB

SB

Hi Algar_emi. On the power amp pcb I used BC550C/560C in place of the PN100A/200A pair ( as I did on the input board too ). I did this because I had plenty of closely matched BC550C/560C pairs but no matching PN100A/PN200A pairs ( huge difference between Hfe of npn and pnp devices ). Also the PN100A/200A are now obsolete. I'm still experimenting with the output stage transistors to try and get a stable amp with modern high ft transistors that I can match ( impossible with the default types ).

So you mean that if I get the power pcb I got assemble it with current offering parts, like

MJL21193G/94G final, 2N5551/5401, MJE15030/31 & MJE182 or these are ok?

Thanks

SB

MJL21193G/94G final, 2N5551/5401, MJE15030/31 & MJE182 or these are ok?

Thanks

SB

Yes of course. Amplitude assembled his amps using all of the standard parts in the BOM, including PN100A/200A. The performance and sound is/was very good, but not quite as good as an original Bryston because it's impossible to match the parts as well as Bryston do. I'm trying to use alternative semiconductors which can be matched to give performance on a par to the Bryston. This is not too much of a problem except for the output devices. Bryston use carefully matched, low ft output devices. I've bought small quantities of all of the low ft output devices I can find but the npn/pnp matching is very poor in general. I do however have three or four different types of higher ft output device pairs which are very well matched. If you use these in the circuit, as is, then you get instability, so I'm trying to find a way of stabilising the amp with output devices where the ft is around 30MHz rather than 4MHz. Just for the fun of it and because I'm a bit ocd.

Yes it performs very nice, even with the standard parts, perhaps I got lucky 🙂

But that was many audio projects ago, it's like heroin this diy, I'm not at the point where I have to burgled houses late night, but I, getting there 🙂 latest project is the reason for this addiction, as teenager drowling about hafler p500 and the famous, now cult amplifier, the big leach power amp, great project, but the cabeling is a nightmare, and chassis likewise.

But that was many audio projects ago, it's like heroin this diy, I'm not at the point where I have to burgled houses late night, but I, getting there 🙂 latest project is the reason for this addiction, as teenager drowling about hafler p500 and the famous, now cult amplifier, the big leach power amp, great project, but the cabeling is a nightmare, and chassis likewise.

Attachments

Yes of course. Amplitude assembled his amps using all of the standard parts in the BOM, including PN100A/200A. The performance and sound is/was very good, but not quite as good as an original Bryston because it's impossible to match the parts as well as Bryston do. I'm trying to use alternative semiconductors which can be matched to give performance on a par to the Bryston. This is not too much of a problem except for the output devices. Bryston use carefully matched, low ft output devices. I've bought small quantities of all of the low ft output devices I can find but the npn/pnp matching is very poor in general. I do however have three or four different types of higher ft output device pairs which are very well matched. If you use these in the circuit, as is, then you get instability, so I'm trying to find a way of stabilising the amp with output devices where the ft is around 30MHz rather than 4MHz. Just for the fun of it and because I'm a bit ocd.

I bought 2nd sets of PCB but still stuck in few problems faced in 1st 4bsst.....

1) heating Q5,6 In input board....solutions were given by Chalky but those parts are not available in my country

2)Big cabinet are not available and trying to Custum make....any one have CAD drawing for aluminium cabinet for this amp ?

3) Difficult in matching output devices

4) Low output power when compared to my Yamaha AVR which have 4 transistors in output stage.

The chassis is build up around a square pipe steel frame, I had it from a old project, the heatsinks I also had, they were 300mm so i cut them in half for better chassis fitting and better airflow, they are pre drilled for to-3, so perfect, they are used and showed a bit wear, so I put them in a mild acid bath, and etched the surface, I looked for anodization company but prices were sky high.

All aluminium is bought on Ebay, a german company the price was very fair, but their metal cutter needs sharpening, the 8mm front plate had been compressed in the cut line, so I had to use a band saw and cut off a few mm, I'm going to phase all edges with a wood router with carbide bit.

So it's quite easy but time consuming, I didn't make a lot of drawings but build it from my mind, a bit risky I admit, driver boards will be shielded with a u shape profile, cause the toroid is pretty close to boards, hmm will add a relay volume control to it.

So make up a drawing , a look for a supplier that is willing to cut materials to your specs, and if possible get a friend who has access to metal working tools, blacksmith cnc operator ?

A good amp deserves a nice chassis, especially if you're married and have to obey the waf factor, I'm playing music on a hiraga 30w without chassis and it's not popular with the misses, so another chassis is needed

All aluminium is bought on Ebay, a german company the price was very fair, but their metal cutter needs sharpening, the 8mm front plate had been compressed in the cut line, so I had to use a band saw and cut off a few mm, I'm going to phase all edges with a wood router with carbide bit.

So it's quite easy but time consuming, I didn't make a lot of drawings but build it from my mind, a bit risky I admit, driver boards will be shielded with a u shape profile, cause the toroid is pretty close to boards, hmm will add a relay volume control to it.

So make up a drawing , a look for a supplier that is willing to cut materials to your specs, and if possible get a friend who has access to metal working tools, blacksmith cnc operator ?

A good amp deserves a nice chassis, especially if you're married and have to obey the waf factor, I'm playing music on a hiraga 30w without chassis and it's not popular with the misses, so another chassis is needed

- Home

- Amplifiers

- Solid State

- Bryston 4B SST clone