Hi Warren,

"The EPC205 sound amazing in this arm. Quiet passages are eerily silent. If I were to sum this up in a few words - Dynamic, Clarity, Detail and it sucks you into the music..........I love it"

Welcome to the "no bending modes in the audio band club"

Niffy

"The EPC205 sound amazing in this arm. Quiet passages are eerily silent. If I were to sum this up in a few words - Dynamic, Clarity, Detail and it sucks you into the music..........I love it"

Welcome to the "no bending modes in the audio band club"

Niffy

It looks great! - do you feel its reduced friction of the pin bearing wheels that's brought this improvement, or something else? - i really like the idea of hearing eerily silent........so when you cue a track, just a click as the stylus touches down, no discernible hiss/rustle of typical vinyl noise?

Hi Mike,

The reduced starting torque with the pin bearings certainly improved the situation with the Stanton, and I tried it without the brush as a worst case scenario. The 881s is a very high compliance cartridge and needs a light arm.

The EPC205 with the Jico SAS / Boron CL is a great cartridge. In fact the ECP205mk3 has one of the lightest moving masses of any cartridge published and is lighter than most MC's.

There is still stylus in groove noise in the lead in/out and in between tracks but it is very much attenuated over my pivoting arm. What is almost totally missing are clicks/pops and noise in quiet music passages.

The YouTube photos are great.

In all cases, your disc and TT are not concentric. To my eyes, the arm seems to be overshooting the groove centerline. I also can't tell if the overshoot is symmetric.

All I can do is ask if you see the above overshoot. The questions, then, are (1) can you hear the difference, and if so (2) does it matter? Your personal assessment seems to be "yes" for both, but then it's hard to criticize your own child objectively.

Hi Andy,

The LP playing is an old kids LP I elongated the hole significantly to make a torture test. Yes there is overshoot as the CL is still wobbling slightly, any tonearm cartridge will over shoot on an off centre pressing even the best, this is physics at work. The more mass moving the longer it takes to change direction. In a low compliance MC you just might not see it because of the stiff suspension but stylus to groove wall pressure will change.

First I was not listening to this LP as this was a visual test.

Yes I can hear the difference. My reference arm is a Technics EPA100 known for it's ruby bearings and on of the lowest starting torques of any tonearm. This LTA now significantly out performs the EPA100 on my worst off centre pressing Neil Diamond Stones.

Not quite sure what you mean in 2 so I'll just ramble. I am my own worst critic, this is why I spent time rebuilding the arm. Also any tonearm is a compromise and it comes down to what compromises you desire to make. In this case I think what Niffy said about the lack of bending modes in the extremely rigid carriage more than offset the better off centre tracking in a longer arm.

diyrayk & Straight Tracker have published straight-line tracking designs that compensate for overshoots using mechanical and electro-mechanical means. I would like to know if they can handle overshoot, and how well. Compensation, of course, is not a cure. It is slow, unlike electronic feedback, and is re-active, not pro-active. In the end, the same 2 questions apply. If correction is good enough, such artifacts as remain constitute a "don't care".

Andy

awolff761

Funny you say this as I was thinking about experimenting and building a Rabco style arm, Sero/Mechanical with gimbal bearings. Just need to think how I reduce bending modes in the long arm needed.

You will never stop overshoot even with a servo arm. The Rabco uses a pivot arm on a sevo, but overshoot will be governed by arm/cartridge mass in the pivoting part, a very light arm wand will reduce overshoot but not eliminate it.

It's not a matter of don't care it is a matter of what artifacts you are prepared to put up with, in a longer arm you are putting up with bending modes to potentially reduce overshoot on off centre pressings. My question is which artifact is worse.

Last edited:

I see what you are getting at. Might be a good solution. But you get a side thrust on the cantilever every time you are dealing with a warp. That could cause problems.

So the parallelogram should have a fixed vertical side on the carriage, and horizontal pivot bars so that vertical movement on the cartridge carrier is tangential and has tiny angles only in a warp movement, i had also originally started with it paralell to the groove tangent but its more complicated to put the stylus in line with the wheels and keep mass very low

I have to give this a try at some point, could you kindly point to the post that gives best and latest detail of simple pin bearing wheels and i will start collecting parts! - thanks, mikeHi Mike,

The reduced starting torque with the pin bearings certainly improved the situation with the Stanton, and I tried it without the brush as a worst case scenario. The 881s is a very high compliance cartridge and needs a light arm.

The EPC205 with the Jico SAS / Boron CL is a great cartridge. In fact the ECP205mk3 has one of the lightest moving masses of any cartridge published and is lighter than most MC's.

There is still stylus in groove noise in the lead in/out and in between tracks but it is very much attenuated over my pivoting arm. What is almost totally missing are clicks/pops and noise in quiet music passages.

Niffy, could you kindly point to the detail of these bearings/setup/sourcing etc, you've kindly done all the hard work and i would like to make the best copy i can, simple as i can also as a start point, i've searched but not found it yetIt's largely down to budget and building skill. Ballrace bearings are much cheaper, easier to make and more readily available.

Really good results can be achieved with ballrace bearings. The first linear arm I built, about 25 years ago, was a mess. I got a lot wrong. I had the good fortune to have two identical high end decks (pink triangle anniversary) and two identical cartridges (ortofon mc3000) at my disposal. One deck was fitted with an SME V the other with my badly built first attempt. My arm easily bested the SME. Warrjon recently reported his ballrace based arm "smoking" his reference arm.

In developing my bearings I went through several stages starting with pivots made from sewing pins, vees from grub screws and steel wheels. These were as cheap to make as ballrace bearings but took a lot more work. The sound quality with these bearings was notably better than the ballrace version. The move to jeweled bearings and all the tungsten carbide elevated the sound quality by a substantial amount. If you want the best possible mechanical bearing then I would definitely recommend my system.

I believe that I am the only one who has a working arm with jeweled bearings, tungsten carbide rails and wheels. (I think Joe is close to a working arm). I would really like to have some feedback from other builders who have built both ballrace and jeweled/carbide to see if their results match mine. So far you are relying on a sample size of one.

Niffy

Hello,

I have been absent from this thread for about a year, and it interesting to see the topics evolve

My 2 cents on the active arm discussion:

Active is the way to go, the surface of the needle that touches the vinyl varies between 20 and 40 square micrometer- depending on the shape- this surface must move the 20 grams or so effective mass of the arm+friction of the bearing

The compliance of the cartridge wil have to deal with this, putting loads on the groove and coil alignments after the pivot. These forces can only be mitigated by an active compensating movement of sufficient accuracy

There a lot of mentions of “servo” -these are Brushless Direct Current motors (BLDC)- the other type are stepper motor- these are the ones used in the 30k Dereneville TA- each type has its own (dis) advantages.

I favor steppers, because the positioning between min and max arm positions can be exactly set. There is a new class of steppermotor drivers that are extremely quiet and can position 51200 steps/rotation- the limit is the sensitivity of the TA’s sensor array- in case of the Dereneville: 5 microns -(laser measuring)

Dereneville

I also would like to ask more regular Active TA minded contributors of this thread to start a dedicated thread on active TA’s

Have a great day

Thx

C

I have been absent from this thread for about a year, and it interesting to see the topics evolve

My 2 cents on the active arm discussion:

Active is the way to go, the surface of the needle that touches the vinyl varies between 20 and 40 square micrometer- depending on the shape- this surface must move the 20 grams or so effective mass of the arm+friction of the bearing

The compliance of the cartridge wil have to deal with this, putting loads on the groove and coil alignments after the pivot. These forces can only be mitigated by an active compensating movement of sufficient accuracy

There a lot of mentions of “servo” -these are Brushless Direct Current motors (BLDC)- the other type are stepper motor- these are the ones used in the 30k Dereneville TA- each type has its own (dis) advantages.

I favor steppers, because the positioning between min and max arm positions can be exactly set. There is a new class of steppermotor drivers that are extremely quiet and can position 51200 steps/rotation- the limit is the sensitivity of the TA’s sensor array- in case of the Dereneville: 5 microns -(laser measuring)

Dereneville

I also would like to ask more regular Active TA minded contributors of this thread to start a dedicated thread on active TA’s

Have a great day

Thx

C

Last edited:

Warrjon,

Thanks for your reply. You answered most of my questions, in a different order. I have some clarifications.

1) It was obvious from your first photo that it was a sort of worst-case, but the other two were not. Therefore, I asked if you could see the overshoot there, and could you hear it, and whether it deserved further effort to eliminate it.

2) There are many visual errors that you can dismiss because they don't sound worse (e.g. they reduce separation, or only show up in the absence of a spindle clamp), so I asked if these were "don't-care", my term for them.

3) Critiquing your own arm is hard. Several contributors since have asked for the opinions of others on various topics.

4) This is never settled, whether we use test records, 'scope traces etc. because we, our ears, our systems, rooms, preferred music etc are all different. I just wanted your take on how you finally determine something is better, since your posts reflect a different and often superior sensitivity in areas I am interest in.

5) In a similar way, you mention arm bending modes. This is a large topic, since it involves strength of materials (what aluminum type & thickness, round or square) & length. Then their are carbon film tubes, ease of working it (or not), using holes to offset arm weight, and cost/availability. As soon as you mention something, our minds start to evaluate (the price of being human!).

Keep posting!

Thanks, Andy

Thanks for your reply. You answered most of my questions, in a different order. I have some clarifications.

1) It was obvious from your first photo that it was a sort of worst-case, but the other two were not. Therefore, I asked if you could see the overshoot there, and could you hear it, and whether it deserved further effort to eliminate it.

2) There are many visual errors that you can dismiss because they don't sound worse (e.g. they reduce separation, or only show up in the absence of a spindle clamp), so I asked if these were "don't-care", my term for them.

3) Critiquing your own arm is hard. Several contributors since have asked for the opinions of others on various topics.

4) This is never settled, whether we use test records, 'scope traces etc. because we, our ears, our systems, rooms, preferred music etc are all different. I just wanted your take on how you finally determine something is better, since your posts reflect a different and often superior sensitivity in areas I am interest in.

5) In a similar way, you mention arm bending modes. This is a large topic, since it involves strength of materials (what aluminum type & thickness, round or square) & length. Then their are carbon film tubes, ease of working it (or not), using holes to offset arm weight, and cost/availability. As soon as you mention something, our minds start to evaluate (the price of being human!).

Keep posting!

Thanks, Andy

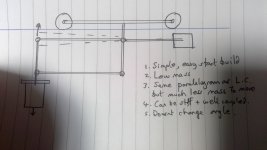

So the parallelogram should have a fixed vertical side on the carriage, and horizontal pivot bars so that vertical movement on the cartridge carrier is tangential and has tiny angles only in a warp movement, i had also originally started with it paralell to the groove tangent but its more complicated to put the stylus in line with the wheels and keep mass very low

A sketch please, I can't follow you

A sketch please, I can't follow you

Hi Koldby, that's most probably because its most likely a poor idea, however, herewith my sketch and background notes!

mike

Attachments

Hi Koldby, that's most probably because its most likely a poor idea, however, herewith my sketch and background notes!

mike

It is actually a Lil Casey parrallelogram you have placed under the sledge. I have had the same thoughts and it could be a solution.

Has anyone considered a 'scissorlift' type of setup directly under the sled?

That would allow the cartridge to move absolutely vertically, but would be a challenge to build due to the small size and small bearings required.

That would allow the cartridge to move absolutely vertically, but would be a challenge to build due to the small size and small bearings required.

See answers in Blue

1) It was obvious from your first photo that it was a sort of worst-case, but the other two were not. Therefore, I asked if you could see the overshoot there, and could you hear it, and whether it deserved further effort to eliminate it.

All 3 videos used the same off centre LP I answered your question in my last post "Yes there is overshoot as the CL is still wobbling slightly" Can I hear it in another off centre LP Neil Diamond Stones no I can not. The LTA has far less surface noise and greater dynamics than the pivoting arm.

2) There are many visual errors that you can dismiss because they don't sound worse (e.g. they reduce separation, or only show up in the absence of a spindle clamp), so I asked if these were "don't-care", my term for them.

I am not dismissing anything you are making assumptions that I am happy with my LTA and will not develop it further. This is an incorrect assumption. Is this LTA better than my EPA100 on the other SP10 - yes it is in most areas. Certainly it has far lower noise floor, better dynamics and bass response. The EPA100 beats it in imaging.

The EPA100 is an extremely good pivoting arm the Titanium nitride arm wand is extremely stiff and its noise floor is very low for a 10" arm. It also has the lowest starting torque and bearing friction of ANY gimbal bearing tonearm made, so I have very good reference.

3) Critiquing your own arm is hard. Several contributors since have asked for the opinions of others on various topics.

Unfortunately I live in a rural area 100's miles from a city so there are few audiophiles around here to come over and listen to my system. So I am left to my own devices. If I built rotary dairies to milk cows I would have no problem getting someone to come over.

I wish there was someone who could come and critique this for me but alas no.

As a fully qualified electronic technician and engineer I have enough objectivity to continue to develop this arm to solve the one major issue I see, and that is carriage inertia which is causing the OVERSHOOT as you call it.

4) This is never settled, whether we use test records, 'scope traces etc. because we, our ears, our systems, rooms, preferred music etc are all different. I just wanted your take on how you finally determine something is better, since your posts reflect a different and often superior sensitivity in areas I am interest in.

I have loads of test LP's and these are used in the development phase, once I get close then listening is the key. I have a few specific tracks I use to evaluate differences. One is Elvis's Old Shep and the LTA does not do a good job on this track, I can hear distortion in the right channel, which is not there with the EPA100. So I know I have some refinements to do the LTA.

I have no explanation for this as yet because that Elvis LP is not off centre. The worst off centre pressing I have is Neil Diamond Stones and the LTA tracks this and sounds superior to the EPA.

5) In a similar way, you mention arm bending modes. This is a large topic, since it involves strength of materials (what aluminum type & thickness, round or square) & length. Then their are carbon film tubes, ease of working it (or not), using holes to offset arm weight, and cost/availability. As soon as you mention something, our minds start to evaluate (the price of being human!).

True, material and composite construction has a large effect on this. A good rule of thumb though is the shorter the arm the higher the first bending mode frequency. Speed of sound in the material will effect this, but will be uniform for the same material.

In my research it's the 3rd harmonic that is the worst, so if the main bending mode is above 10kHz then the 3rd is 30kHZ well out of the audio band.

My next upgrade is to add a servo driven main arm which will be rigidly fixed to the carriage so no vertical or horizontal movement in the main arm. this will be mounted to the current bridge so the servo will be over the LP making the main arm short.

Then a mechanical vertical horizontal headshell. Maybe something like a very small version of Carlo's Lil Casey on the end of the main arm.

This is my current setup. Unfortunately I do not have 2 EPC205c cartridges so the EPA has the Stanton 881 mounted.

.

1) It was obvious from your first photo that it was a sort of worst-case, but the other two were not. Therefore, I asked if you could see the overshoot there, and could you hear it, and whether it deserved further effort to eliminate it.

All 3 videos used the same off centre LP I answered your question in my last post "Yes there is overshoot as the CL is still wobbling slightly" Can I hear it in another off centre LP Neil Diamond Stones no I can not. The LTA has far less surface noise and greater dynamics than the pivoting arm.

2) There are many visual errors that you can dismiss because they don't sound worse (e.g. they reduce separation, or only show up in the absence of a spindle clamp), so I asked if these were "don't-care", my term for them.

I am not dismissing anything you are making assumptions that I am happy with my LTA and will not develop it further. This is an incorrect assumption. Is this LTA better than my EPA100 on the other SP10 - yes it is in most areas. Certainly it has far lower noise floor, better dynamics and bass response. The EPA100 beats it in imaging.

The EPA100 is an extremely good pivoting arm the Titanium nitride arm wand is extremely stiff and its noise floor is very low for a 10" arm. It also has the lowest starting torque and bearing friction of ANY gimbal bearing tonearm made, so I have very good reference.

3) Critiquing your own arm is hard. Several contributors since have asked for the opinions of others on various topics.

Unfortunately I live in a rural area 100's miles from a city so there are few audiophiles around here to come over and listen to my system. So I am left to my own devices. If I built rotary dairies to milk cows I would have no problem getting someone to come over.

I wish there was someone who could come and critique this for me but alas no.

As a fully qualified electronic technician and engineer I have enough objectivity to continue to develop this arm to solve the one major issue I see, and that is carriage inertia which is causing the OVERSHOOT as you call it.

4) This is never settled, whether we use test records, 'scope traces etc. because we, our ears, our systems, rooms, preferred music etc are all different. I just wanted your take on how you finally determine something is better, since your posts reflect a different and often superior sensitivity in areas I am interest in.

I have loads of test LP's and these are used in the development phase, once I get close then listening is the key. I have a few specific tracks I use to evaluate differences. One is Elvis's Old Shep and the LTA does not do a good job on this track, I can hear distortion in the right channel, which is not there with the EPA100. So I know I have some refinements to do the LTA.

I have no explanation for this as yet because that Elvis LP is not off centre. The worst off centre pressing I have is Neil Diamond Stones and the LTA tracks this and sounds superior to the EPA.

5) In a similar way, you mention arm bending modes. This is a large topic, since it involves strength of materials (what aluminum type & thickness, round or square) & length. Then their are carbon film tubes, ease of working it (or not), using holes to offset arm weight, and cost/availability. As soon as you mention something, our minds start to evaluate (the price of being human!).

True, material and composite construction has a large effect on this. A good rule of thumb though is the shorter the arm the higher the first bending mode frequency. Speed of sound in the material will effect this, but will be uniform for the same material.

In my research it's the 3rd harmonic that is the worst, so if the main bending mode is above 10kHz then the 3rd is 30kHZ well out of the audio band.

My next upgrade is to add a servo driven main arm which will be rigidly fixed to the carriage so no vertical or horizontal movement in the main arm. this will be mounted to the current bridge so the servo will be over the LP making the main arm short.

Then a mechanical vertical horizontal headshell. Maybe something like a very small version of Carlo's Lil Casey on the end of the main arm.

This is my current setup. Unfortunately I do not have 2 EPC205c cartridges so the EPA has the Stanton 881 mounted.

.

Attachments

Last edited:

Has anyone considered a 'scissorlift' type of setup directly under the sled?

That would allow the cartridge to move absolutely vertically, but would be a challenge to build due to the small size and small bearings required.

I sketched that as well, and thought it promising, but it requires something to stop rotation(looking face on at the cartridge), and i thought that more difficult or heavier

I can hear distortion in the right channel, which is not there with the EPA100. So I know I have some refinements to do the LTA.[/COLOR]

I have no explanation for this as yet because that Elvis LP is not off centre. The worst off centre pressing I have is Neil Diamond Stones and the LTA tracks this and sounds superior to the EPA.

I am sure this is just an area i have yet to understand but somewhere the force to move the carriage from the record edge to centre has to be applied, is that what loads the right channel? - or is the length of groove its over sufficiently long its effectively zero?

The force that drives the carriage is the longitudinal drag on the stylus. This force is inline with the cantilever. The waggle of the CL in my video is caused by inertia of the carriage. Any mass moving takes time to stop and the heavier the mass the longer it takes to stop.

In my case the distortion is most likely alignment for the microline stylus. I need to do more investigation here to determine the issue.

In my case the distortion is most likely alignment for the microline stylus. I need to do more investigation here to determine the issue.

The force that drives the carriage is the longitudinal drag on the stylus. This force is inline with the cantilever. The waggle of the CL in my video is caused by inertia of the carriage. Any mass moving takes time to stop and the heavier the mass the longer it takes to stop.

In my case the distortion is most likely alignment for the microline stylus. I need to do more investigation here to determine the issue.

Thanks Warrjon, i am getting closer to collecting some parts and having a go......for me this also has to be a very low cost exploration, so the jewel route is probably out, earlier you suggested MR104's could be a good start, but equally if that's going to lead to skipping that's a non starter for me, so in between, i see all ceramic miniature bearings suggested to be lower friction and lubricant free, just wondering if anyone went there and if its useful found a good supplier?

thanks

Mike

Hi Mike,

I have both a set of hybrid ceramic BOCA AEBC9 bearings and set of regular MR104. I had to de-grease the MR104's, but in my first LTA with the very light carriage they worked perfectly and tracked my EPC205c fine, the Stanton 881s is a challenge for a pivot arm.

I have both a set of hybrid ceramic BOCA AEBC9 bearings and set of regular MR104. I had to de-grease the MR104's, but in my first LTA with the very light carriage they worked perfectly and tracked my EPC205c fine, the Stanton 881s is a challenge for a pivot arm.

Thanks Warrjon.

Your replies were quite thorough. Not everyone goes into such detail in these posts, so I declare gratitude and admiration.

The assumption in item 2 was wrong: my bad.

Some food for thought in your #4 (you mention it, I immediately think on it, as I said!): If you have followed the VTA (Vertical Tracking Angle error) controversy, the authors of the most-thorough investigation of it (Maier & Risch) concluded 2 things.

(1) VTA is hard to isolate and even harder to hear, so maybe it should be a don't-care (sorry).

(2) SRA (Stylus Rake Angle error), in contrast, is both easier to hear and to measure. Perhaps this parameter is pertinent to your investigations. There is also stylus fit to the groove, so you may have to get even deeper into the whole Shibata/Geiger/Jico etc. stylus muck. (Should that be Gyger?).

You are into an area where even the mfr of a Stanton vs a Matsushita cart and their generators matter.

Andy

Your replies were quite thorough. Not everyone goes into such detail in these posts, so I declare gratitude and admiration.

The assumption in item 2 was wrong: my bad.

Some food for thought in your #4 (you mention it, I immediately think on it, as I said!): If you have followed the VTA (Vertical Tracking Angle error) controversy, the authors of the most-thorough investigation of it (Maier & Risch) concluded 2 things.

(1) VTA is hard to isolate and even harder to hear, so maybe it should be a don't-care (sorry).

(2) SRA (Stylus Rake Angle error), in contrast, is both easier to hear and to measure. Perhaps this parameter is pertinent to your investigations. There is also stylus fit to the groove, so you may have to get even deeper into the whole Shibata/Geiger/Jico etc. stylus muck. (Should that be Gyger?).

You are into an area where even the mfr of a Stanton vs a Matsushita cart and their generators matter.

Andy

Last edited:

Hi Mike,

I have both a set of hybrid ceramic BOCA AEBC9 bearings and set of regular MR104. I had to de-grease the MR104's, but in my first LTA with the very light carriage they worked perfectly and tracked my EPC205c fine, the Stanton 881s is a challenge for a pivot arm.

Many thanks again, I have found SMB bearings here and they offer them dry.

Sorry to keep asking, i know i have seen it somewhere, what is the best wiring thought currently please (at reasonable cost)?

- Home

- Source & Line

- Analogue Source

- DIY linear tonearm