Hello guys is been a long time I was just messing with Arc Welder II 🙂 anyone interested on the Sprint files?

Do you have the schematic for the above pcb design and also what are the OPS transistors?

same as Arc Welder just wiht more pairs

it use BJT or FET's is noting new here 🙂Do you have the schematic for the above pcb design and also what are the OPS transistors?

Attachments

Hello guys is been a long time I was just messing with Arc Welder II 🙂 anyone interested on the Sprint files?

Yesyes

Do you have a class h scheme?it use BJT or FET's is noting new here 🙂

Do you have a class h scheme?

I only gonna cover Ostripper design's subject here he hasn't post any class H that I know also I'm only do modification of the layout that Mr. JKuteman did please keep subject relate to Ostripper design not out of subject related to other designs 🙂

I think all that he is saying is that can you combine the "power supply design" OF the green amp that Ostripper designed into the Arc welder schematic and therefore the PCB. Personally I would love to see that done. It would make a great or greater 400 watt amp. Thanks

I made the Grenamp layout a few months ago is double layer and after I tested sounds really good I like the design of Ostripper because you can try other types of IPS oh! I having seen OS's power supply design?

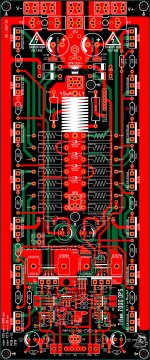

hey guys I'm gonna leave the Arc Welder Titan 7000 here please check before order the PCB's here is the files, if any error please let me know so I can corrected right away 🙂

Best Regards

Juan

Best Regards

Juan

Attachments

LORD OSTRIPPER IN MY COUNTRY IT IS DIFFICULT TO GET MUR460 I COULD USE THIS FR607

posting in all caps is against forum rules...

posting in all caps is against forum rules...PLEASE HAVE A CFA CLAS H SCHEME, GIVE HERE

please do nto post in all caps,it's against our rules...

please do nto post in all caps,it's against our rules...hey guys I have a question I recently purchase a drill press so I can work better the heat sinks drilling jobs the 4-40 screws can be use on power transistors like the MJL3281A On brand? or M3 screws?

The datasheet will normally give dimensions for transistor packages. Most metal tabbed transistors will have holes sized for a standard thread size plus an insulating bushing. I believe M3 is common for most packages, certainly TO247 and TO220 seem to have 3.5mm hole, which fits M3+bushing.

I prefer M3 screws and so do some of the guys who build amps in the USA.

For holes that go right through, I put the tap on a cordless drill, on a low setting.

For blind holes I put the tap in the drill press and turn slowly by hand. The drill press keeps the tap perpendicular but as you can guess it's a slow process.

I always use WD40 or a cutting fluid. Some times I stop the tapping to vacuum the junk that has fallen into the blind hole.

Experiment on some old aluminium first.

For holes that go right through, I put the tap on a cordless drill, on a low setting.

For blind holes I put the tap in the drill press and turn slowly by hand. The drill press keeps the tap perpendicular but as you can guess it's a slow process.

I always use WD40 or a cutting fluid. Some times I stop the tapping to vacuum the junk that has fallen into the blind hole.

Experiment on some old aluminium first.

I prefer M3 screws and so do some of the guys who build amps in the USA.

For holes that go right through, I put the tap on a cordless drill, on a low setting.

For blind holes I put the tap in the drill press and turn slowly by hand. The drill press keeps the tap perpendicular but as you can guess it's a slow process.

I always use WD40 or a cutting fluid. Some times I stop the tapping to vacuum the junk that has fallen into the blind hole.

Experiment on some old aluminium first.

thank you for responds yes I will practice on scrap aluminum first yes good thinking 🙂

i also use the singer sewing machine oil, tapmatic fluid, and wd40 when drilling ang tapping holes...

I've found the drilling is as important as the tapping. Use a sharp bit, tapping oil and go slowly. If you heat up the aluminium when drilling it will temper it and will make tapping it much more difficult.

I've found the drilling is as important as the tapping. Use a sharp bit, tapping oil and go slowly.

I agree. I use soapy water for drilling, and tapping screw to fixing the transistors.

Sajti

Drill speed

Discussion here:

RPM to drill aluminum or steel?

If the formula is correct-

3mm = 0.11811"

600/ 0.11811 = 5080RPM for aluminium

Discussion here:

RPM to drill aluminum or steel?

If the formula is correct-

3mm = 0.11811"

600/ 0.11811 = 5080RPM for aluminium

Last edited:

- Home

- Amplifiers

- Solid State

- Slewmaster - CFA vs. VFA "Rumble"