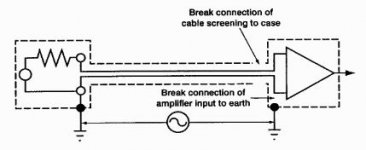

Pavel, understood, I'm using cheapest RCA connectors with cable braid soldered evenly around connector shell. It looks that the RCA-shielded twisted pair with the shield connected on the source side-RCA is the worst case for ground loop current according to your setup

Attachments

Howie,

sound very reasonable, thanks! 🙂

Testing wires rather than complete cables does make things easier for me, actually. Connector count halved, system simplified. The uC-controlled bank of relays that I will need for syncronized switching of direction is already enough of a task...

sound very reasonable, thanks! 🙂

Testing wires rather than complete cables does make things easier for me, actually. Connector count halved, system simplified. The uC-controlled bank of relays that I will need for syncronized switching of direction is already enough of a task...

In the typical playback system, connecting wires are used in pairs; signal is separate left and right on the inner conductors but both are shared on both outer conductors/ shields. Does testing one wire separately adequately predict this typical case?

All good fortune,

Chris

All good fortune,

Chris

As far as the Forwood book is concerned, I would have posted most of the pages of interest, as I have done several times on this website over the decade(s) if I could find it on my computer, but Gpapag you are going to see a book that is above and beyond what it normally discussed here, and it should be enlightening.

Mr. Curl

You may post the pages you find are of interest when you are ready.

I have read a few metallurgy and material science books so far, so I don’t have great expectations this book will open a window to the world for me.

In a month or two the technical library will have it.

Also considering that wire drawing deforms the wire directionally, I think it is safe to assume that discontinuities and dislocations will have a mechanical directional bias or asymmetry.

Incidently, Indra mentioned annealing.

Dan, this process should draw your attention and sooth this neurotic assumption that dislocations within the metal are the cause of the mythical directionality in conducting (AC mind you) electrical signals in a wire .

Have you tried reading what annealing does to metals in general and to copper in particular? How is it performed? Have you heard of loop annealing?

Dan how well are you informed on the wire drawing processes used in factories before drawing conclusions? Processes, engineering, metallurgical details?

Cold drawing at these high speeds that modern equipment is working today, isn’t exactly “cold”.

600d Celsius is readily achieved during drawing wire through the formers (friction) and this is above the ½ melting temperature of copper. You know what effect has this on copper?

This is a whole new world. Be willing to study before safely assuming such assumptions

PS. Just knowing how easily new dislocations are induced in a copper wire by simply bending the wire during normal handling, makes the whole scenario of dislocations-generated wire electrical directionality a good joke.

George

Well tonight I actually ordered some lead. My SME 3009 SIII is missing half it's counterweights (they all generally are) and I plan to finally get it comissioned soon. Not paying ebay prices so going to make my own. And smile as they aren't allowed to make them this way anymore. Shame really as it's a think of beauty to just hold in your hand and seems so delicate compared to its younger sibling 309. It also marks an interesting point in audio evolution, where low mass and low friction were swept aside in the rush to support the brutish wave of low compliance MCs that became fashionable.

These days as vinyl replay is about the experience rather than the quality we can appreciate these wonders of precision engineering far more I reckon.

These days as vinyl replay is about the experience rather than the quality we can appreciate these wonders of precision engineering far more I reckon.

PS. Just knowing how easily new dislocations are induced in a copper wire by simply bending the wire during normal handling, makes the whole scenario of dislocations-generated wire electrical directionality a good joke.

George

yep.

🙂 😎

-RNM

I've heard that the English<French<Roman<Greek word "person" originally meant "the voice behind the mask". In this context it's easier to see the "personhood" of the dogs and cats and raccoons we live with.

All good fortune,

Chris

person | Origin and meaning of person by Online Etymology Dictionary

person (n.)

early 13c., from Old French persone "human being, anyone, person" (12c., Modern French personne) and directly from Latin persona "human being, person, personage; a part in a drama, assumed character," originally "a mask, a false face," such as those of wood or clay worn by the actors in later Roman theater. OED offers the general 19c. explanation of persona as "related to" Latin personare "to sound through" (i.e. the mask as something spoken through and perhaps amplifying the voice), "but the long o makes a difficulty ...." Klein and Barnhart say it is possibly borrowed from Etruscan phersu "mask." Klein goes on to say this is ultimately of Greek origin and compares Persephone.

Phersu (in Greek) is the imperative present form of the verb “ pheromae”, meaning to behave in a certain manner.

See how things cling together!

PS. Use of theatric masks is dated (documented) during classical years ~500BC, much earlier than late Roman period

Teaching History with 100 Objects - A Greek theatre mask

George

Here you go GP:

Thank you Mr. Curl. Very kind of you.

I'll come back on this when I read it (tomorrow)

George

Mr. Curl

You may post the pages you find are of interest when you are ready.

I have read a few metallurgy and material science books so far, so I don’t have great expectations this book will open a window to the world for me.

In a month or two the technical library will have it.

Incidently, Indra mentioned annealing.

Dan, this process should draw your attention and sooth this neurotic assumption that dislocations within the metal are the cause of the mythical directionality in conducting (AC mind you) electrical signals in a wire .

Have you tried reading what annealing does to metals in general and to copper in particular? How is it performed? Have you heard of loop annealing?

Dan how well are you informed on the wire drawing processes used in factories before drawing conclusions? Processes, engineering, metallurgical details?

Cold drawing at these high speeds that modern equipment is working today, isn’t exactly “cold”.

600d Celsius is readily achieved during drawing wire through the formers (friction) and this is above the ½ melting temperature of copper. You know what effect has this on copper?

This is a whole new world. Be willing to study before safely assuming such assumptions

PS. Just knowing how easily new dislocations are induced in a copper wire by simply bending the wire during normal handling, makes the whole scenario of dislocations-generated wire electrical directionality a good joke.

George

Having observed in close range these processes in operation I think the first issue is that stranded wire will be in random direction from the reels. It will have been through the drawing dies many times to get to a 30 to 36 AWG gauge for stranding. Then stranding and bunching processes will further mix and randomize the wire. The high purity wire needs special handling since exposure to the environment will degrade the copper and it needs to be processed quickly, however it all starts as 1/4" drawing stock do you can see how there is a lot of processing before its usable.

Then its jacketed which is another hot process. Usually for audio cable, there is more than one insulating/jacketing process so more opportunities for randomization.

If getting it all unidirectional is important the only process I would suggest is CAT 5-7 etc. Those systems/machines take drawing stock at one end and reels in boxes pop out the other end. Asking for a special version is not easy or cheap. You could go through 1000' starting the system up.

Mr. Curl

The pages you kindly posted do not contain any evidence of burn-in effects in electrical conductors.

On the contrary, in two places –see attachment- it is written that grain boundary movement and defect generation was taking place during a time interval where the electron microscope was switched off , so neither the presence of an electron field , nor the electron irradiation or electron beam heating was the cause of these changes in the thin copper foil (if this is what you call as evidence of burn-in )

A side effect (collateral damage) from the posting of those pages is the verification of the ease by which defects (dislocations) are generated or move around in the copper. They show that changes are inevitable and occur all the time

This is really bad news for a directionality hypothesis based on dislocations and metallurgical defects within copper wires

George

The pages you kindly posted do not contain any evidence of burn-in effects in electrical conductors.

On the contrary, in two places –see attachment- it is written that grain boundary movement and defect generation was taking place during a time interval where the electron microscope was switched off , so neither the presence of an electron field , nor the electron irradiation or electron beam heating was the cause of these changes in the thin copper foil (if this is what you call as evidence of burn-in )

A side effect (collateral damage) from the posting of those pages is the verification of the ease by which defects (dislocations) are generated or move around in the copper. They show that changes are inevitable and occur all the time

This is really bad news for a directionality hypothesis based on dislocations and metallurgical defects within copper wires

George

Attachments

Having observed in close range these processes in

.

Thank you Demian once again for providing your valuable experience from the manufacturing floor.

I wish your opinion and suggestions will be noted.

If getting it all unidirectional is important the only process I would suggest is CAT 5-7 etc

That’s funny.

When I read JC post where he asked suggestions for good hook-up wire, I thought to reply that if the gauge is adequate, he would be OK with individual wires from the bundles of CAT 5 wire. (based not on directionality concerns but on the thought that telecommunication industry has far more demanding requirements than audio for the connecting cables and that long runs of not proper wiring would have unacceptable consequences for them. So if CAT 5 wire is the proper wire for them how it can not be good for hook up wire inside audio equipment )

But I said to myself, you will make another public exposure of how cheap you are and I didn't post it.

But here we are again.🙂

George

Demian,

Wow, starting at 1/4 inch dia. Small to start. The stuff I use starts at one foot dia. Goes to 13 mils.

We also use 7 nines copper and aluminum, needed for thermal conductivity at 4 Kelvin.

Yet, with all the smart guys working this stuff, they've seemed to have neglected wire directionality.

I should direct them to Ed and Max, maybe the lead researchers on this planet need to learn reality as it applies to high end audio??

So many world class researchers need to learn this stuff...😀

Jn

Wow, starting at 1/4 inch dia. Small to start. The stuff I use starts at one foot dia. Goes to 13 mils.

We also use 7 nines copper and aluminum, needed for thermal conductivity at 4 Kelvin.

Yet, with all the smart guys working this stuff, they've seemed to have neglected wire directionality.

I should direct them to Ed and Max, maybe the lead researchers on this planet need to learn reality as it applies to high end audio??

So many world class researchers need to learn this stuff...😀

Jn

Probably old hat for you, but there's a youtube interview/walkthrough from a machinist at LBL's fabrication facility, including the wire draw for titanium niobium (I'm probably getting it wrong or misnaming the alloy). Crazy cool stuff.

Last edited:

Demian,

Wow, starting at 1/4 inch dia. Small to start. The stuff I use starts at one foot dia. Goes to 13 mils.

We also use 7 nines copper and aluminum, needed for thermal conductivity at 4 Kelvin.

Yet, with all the smart guys working this stuff, they've seemed to have neglected wire directionality.

I should direct them to Ed and Max, maybe the lead researchers on this planet need to learn reality as it applies to high end audio??

So many world class researchers need to learn this stuff...😀

Jn

You need to put some of Max's magic goop on your magnets. Nobel prize winning stuff I am sure. 😀

Howie,

As you noted cables can have issues that are measurable and can cause problems. As sensitive as my test is, wire directivity is not a clear issue and may only appear under extreme circumstances at a low level.

I did do experiments where I measured wire before and after stressing it. My initial results showed something, but that turned out to be an error. The after stress test had allowed the test equipment to get warmer and that was the difference.

I get the feel that thin wire may have less issues than thicker gauges, but no clear repeatable results. Of course on my large scale projects skin effect can actually make an easily measured difference.

I have noted the peanut gallery has now changed from "cable" to "wire."

As you noted cables can have issues that are measurable and can cause problems. As sensitive as my test is, wire directivity is not a clear issue and may only appear under extreme circumstances at a low level.

I did do experiments where I measured wire before and after stressing it. My initial results showed something, but that turned out to be an error. The after stress test had allowed the test equipment to get warmer and that was the difference.

I get the feel that thin wire may have less issues than thicker gauges, but no clear repeatable results. Of course on my large scale projects skin effect can actually make an easily measured difference.

I have noted the peanut gallery has now changed from "cable" to "wire."

Last edited:

Speaker drivers and headphone drivers do change when 'gooped'.You need to put some of Max's magic goop on your magnets. Nobel prize winning stuff I am sure. 😀

Dan.

No. As long as an amplifier will drive a speaker, this has no meaning the way you seems to see it.Hi-fi (high fidelity) in sound replaying electronics, the degree of output's faithfulness to input is what determines the performance quality.

Compare a flat amplifier with an other that is not linear at all, but compensate the accidents in the response curve of this speaker. Witch one is better ? The one with the less "degree of faithfulness" as you say.

If an amplifier with a lot of distortion is the one that produce the more "natural" or enjoyable sound, witch one is the best ?

When you mix a record, you do it, referring your work on a speaker's system, with the room acoustic of the studio. The best system, at home, the one that will reproduce this mix in the most accurate way is ... the exact same imperfect system. Not a perfect one that do not exists anyway.

it is like cars. Performance numbers on the paper do not tell a lot about the way you will feel on the road. And it is not sure at all that the formula one with the best numbers will win the next race.

You are living in a marvelous but utopian world (on my opinion). The nature has endowed us with senses to perceive the outside world. It is not totally stupid, in hifi as for the rest, to use them to compare the "accuracy" of the sound artifacts that is music reproduction with the idea of the real thing that you can have, that depends on *your* culture.

Oh, yes, culture, subjectivity ....

Numbers are good, it helps during a design process, but it is only the middle of the way. And that is to be welcomed, it would be so boring, otherwise, and this forum would not exists.

Last edited:

Pavel, understood, I'm using cheapest RCA connectors with cable braid soldered evenly around connector shell. It looks that the RCA-shielded twisted pair with the shield connected on the source side-RCA is the worst case for ground loop current according to your setup

What is the contact force like? Usually when I see these they are barely hanging on. You can smash the leaves down but it never works for long.

These might be easier to use:

1 X 567 Socket; RCA; female; straight; crimped; nickel plated, tinned | eBay

The only cable that sounded noticeably different to me was some 10awg stranded aerospace power feeder cable that I used over 20 years ago. And it was better than typical lamp cord, probably was made to reduce emi pickup/transmission, in this case just not picked up by the amplifier.

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- John Curl's Blowtorch preamplifier part III