Mr apex sir ax20 &bx 20 5pair outputs what different and wich is better and powerfull for pa.thank you sir

BA1200 is better for PA.

Hi,

No need to thank as I/we have to thank you for all the help and support that have providing/ed!

Am sorry but there was a small mistake in my post above,When I say thermal coupling,I just put both on a same heatsink (as opposed to attaching both face to face) Q8&9 that is,Where as Q1-2,4-5,6-7 I coupled it treditionally (put them face to face,It was mother of all pain as the layout is not designed for the same,In the bargain broke legs multiple devices 😛). Q6-7 might not yeild any postive result but I still went for it just cause..............

If you match them then almost 0 Dc offset is possible,I myself without matching got almost -0.9mv at one point before breaking the legs!

Hope this helps and I have not caused any problems with my above post.

Regards.

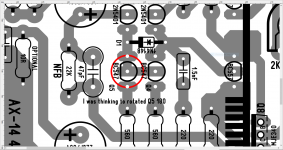

oh I see, I was thinking to couple this ones marked in red to face Q4

Attachments

Hi,

Juan,that's exactly what I have done and had suggested earlier. Only the 340/350 (Q8-9) cannot be done that way is what clarified.

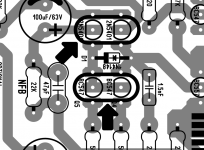

Please refer to the pics,These are Q1-2,Q4-5,Q6-7 (may not visible in the pic) thermally coupled.

Regards.

oh I see, I was thinking to couple this ones marked in red to face Q4

Juan,that's exactly what I have done and had suggested earlier. Only the 340/350 (Q8-9) cannot be done that way is what clarified.

Please refer to the pics,These are Q1-2,Q4-5,Q6-7 (may not visible in the pic) thermally coupled.

Regards.

Attachments

Hi,

Juan,that's exactly what I have done and had suggested earlier. Only the 340/350 (Q8-9) cannot be done that way is what clarified.

Please refer to the pics,These are Q1-2,Q4-5,Q6-7 (may not visible in the pic) thermally coupled.

Regards.

Wouldn't be better to thermally couple Q1-Q2(2N5401) and Q4-Q5(BC547).

Picture you posted you have thermally couple Q1 to Q5 and Q2 to Q4.

Regards

Sonal Kunal

Picture you posted you have thermally couple Q1 to Q5 and Q2 to Q4.

I made mistake 😕.

Q1-Q4 and Q2-Q5 thermally coupled in your picture.

Hi,

Yes I made a mistake too😱 ! Well Sonal are you saying that I couple the same type device ?? i,e 5401 (Q1) with 5401 (Q2), 547 (Q4) with 547 (5) ??

Cuase what I have seen and read are to couple the opposite type device,for example in VSSA PEECEEBEE,Shaan has layed out in such a way that 550 couples with 560. Same in other cases too (at least to what I have seen).

So if you say that it's wrong and I should actually couple Q1-2 (5401 with 5401) and Q4-5 (547 with 547) Then I shall do the same and report back,But would like to know as to why is this ?? Why not as VSSA ??

Juan a big thanks to you for bringing this up as this is proving to be a learning experience !

Regards.

I made mistake .

Q1-Q4 and Q2-Q5 thermally coupled in your picture.

Yes I made a mistake too😱 ! Well Sonal are you saying that I couple the same type device ?? i,e 5401 (Q1) with 5401 (Q2), 547 (Q4) with 547 (5) ??

Cuase what I have seen and read are to couple the opposite type device,for example in VSSA PEECEEBEE,Shaan has layed out in such a way that 550 couples with 560. Same in other cases too (at least to what I have seen).

So if you say that it's wrong and I should actually couple Q1-2 (5401 with 5401) and Q4-5 (547 with 547) Then I shall do the same and report back,But would like to know as to why is this ?? Why not as VSSA ??

Juan a big thanks to you for bringing this up as this is proving to be a learning experience !

Regards.

Wouldn't be better to thermally couple Q1-Q2(2N5401) and Q4-Q5(BC547).

Picture you posted you have thermally couple Q1 to Q5 and Q2 to Q4.

Regards

Sonal Kunal

does make sense I was thinking that also adding a thin copper foil will do the trick wrap those pairs just as mister thimios do on some of his builds and add a bit of thermal compound so I don't have to change the orientation of Q1-Q2 and Q4-Q5 I think 😉

Attachments

...couple the same type device??

In LTP input, current sources and mirrors same polarity BJTs are thermally coupled.

does make sense I was thinking that also adding a thin copper foil will do the trick wrap those pairs just as mister thimios do on some of his builds and add a bit of thermal compound so I don't have to change the orientation of Q1-Q2 and Q4-Q5 I think 😉

I usually use a PC of heats rink and I feel the gap up with the melting glue. That glue has good (enough) heat transfer.

Greets

I usually use a PC of heats rink and I feel the gap up with the melting glue. That glue has good (enough) heat transfer.

Greets

great idea 🙂 sir

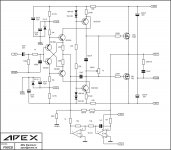

FX9 layout can be modified to FX8CD 😀.

Yes but circuit is not tested.

great idea 🙂 sir

RTV silicone, when cured, is about same as material used for silicone spacer sheets for transistor to heat sink interface. You can use a thin layer of RTV silicone caulking, lay the transistor in place gently to squeeze it flat. Use a few pieces of plastic shim the same thickness as what you want final layer to be (1mm for example) and let it dry with transistor in place. Once cured, it can be trimmed if desired and remove plastic shim.

I also sometimes use one layer of gold Kapton tape for insulation on heatsink, then spread RTV silicone and then place component to be cooled on that and press rather firmly to squeeze out silicone and leave very thin layer for good contact and not worry about shorting.

For thermal bonding two transistors together, a small dab of RTV between the two transistors and squeeze together and wrap with rubber band until cured.

You want the heat to transfer with the least amount of resistance. I can't imagine RTV silicone working.

Not worth the risk IMO. Just not the right application. The goal of the insulator is to provide an electrical insulation with minimal heat loss.

RTV silicone is same material as those blue silicone sheet insulator spacers with some additives. Try it - it works fine.

Also known as Sil-pad

http://www.farnell.com/datasheets/99609.pdf

Or just buy big sheets from China.

http://m.leaderopus.com/silicone-rubber-thermal-insulation-pad

Also known as Sil-pad

http://www.farnell.com/datasheets/99609.pdf

Or just buy big sheets from China.

http://m.leaderopus.com/silicone-rubber-thermal-insulation-pad

Last edited:

- Home

- Amplifiers

- Solid State

- 100W Ultimate Fidelity Amplifier