Again, show your measurements that back up the claim that metal grills in front of THs have "huge consequences" as you've suggested. Where are they, or are you engaging in the same type of baseless handwaving that you're accusing the supporters of "cone correction" of doing?

Refusing to provide any measurements that back up your claims is not gaining YOU any integrity points, LOL.

(BTW - I'll leave you to work out for yourself why you CANNOT use McBean's example sim as "proof" that a grill at the mouth will have "huge consequences". Until then, I'll take it as a sign that you really don't know how to translate a sim to reality, or vice-versa).

I don't have a TH with a grill, or a working mic at this time.

But fortunately neither of those are required to know that a 50 percent blockage ANYWHERE in a horn path is going to change the frequency response pretty dramatically.

Again, I've shown dozens of times, or more, that I can very accurately simulate just about anything. I'm the one always talking about ACCURATE sims, you are now trying to say a 50 percent blockage isn't worth even accounting for.

All this yapping about blockage reminded me there is an ignore function.

Absolutely, although you'll probably find it's not effective unless you set it to 100 percent blockage.

Jag,Anytime you block 50 percent of a port or horn mouth the results are going to be dramatically different than if you didn't block it, as McBean's example very clearly shows. Putting a 50 percent closed grill in front of a cone in a sealed or ported box isn't going to do much of anything, in front of a port or a horn mouth it's going to have huge consequences.

Having measured various plywood blockages reducing the exit of a tapped horn, and also trying 50% closed grill, I can assure you that the grill does not behave like a solid piece of plywood.

To suggest that the consequences of putting a 50% closed grill "in front of a cone in a sealed or ported box isn't going to do much of anything, while in front of a port or a horn mouth it's going to have huge consequences", clearly shows you have measured neither.

Although the distinction between "cone correction" and a "stub" as used by DSL is quite clear to me, I agree with Brian that your assessment of 50% closed grill on a tapped horn is ridiculous.

And to suggest the effect of a grill could be modeled without first making measurements is even more absurd.

Cheers,

Art

A grille will cause some pressure drop. But depending on size of lattice will not affect bass frequencies as a hard boundary that determines acoustic hard edge boundary condition like a throat or mouth edge. Pressure drop of a grille will be minor and can be empirically correlated via pores per unit distance to equivalent losses in Pa/m^2 per m. Kind of like loose stuffing and could be modeled in Akabak as such. But not the same as a hard edge plywood obstruction cutting csa by 50%.

Hmm, I've yet to see a grill [cloth] that does more than attenuate the extreme HF. Even the tiny holes/wide spacing of a perforated cinema screen doesn't have any audible effect on most of the BW. The main thing is to keep it stretched tight, so it can't 'drum'.

edit: Then again, I haven't tested/auditioned any of the newer systems capable of > the old 120 dB/m reference, so at some point in the SPL 'wars' one has to do calculations/testing to see what the max screen mesh is at these ~ 'insane' levels. Oh well, I leave to those who have a need for it.

GM

edit: Then again, I haven't tested/auditioned any of the newer systems capable of > the old 120 dB/m reference, so at some point in the SPL 'wars' one has to do calculations/testing to see what the max screen mesh is at these ~ 'insane' levels. Oh well, I leave to those who have a need for it.

GM

Last edited:

Jag,

Having measured various plywood blockages reducing the exit of a tapped horn, and also trying 50% closed grill, I can assure you that the grill does not behave like a solid piece of plywood.

To suggest that the consequences of putting a 50% closed grill "in front of a cone in a sealed or ported box isn't going to do much of anything, while in front of a port or a horn mouth it's going to have huge consequences", clearly shows you have measured neither.

Although the distinction between "cone correction" and a "stub" as used by DSL is quite clear to me, I agree with Brian that your assessment of 50% closed grill on a tapped horn is ridiculous.

And to suggest the effect of a grill could be modeled without first making measurements is even more absurd.

Cheers,

Art

Context -

This is from a much earlier conversation where Brian was trying to figure out why the 118 measurement did not match his quick and dirty sim. The sim was incredibly inaccurate and didn't account for a lot of things. The discrepancy between sim and measurement was just a few hz and I mentioned that the large driver and the "ledge" rounding the last bend were fairly significant factors when you are looking for a few hz discrepancy.

That driver and that "ledge" are pretty significant.

IIRC when he refused to accept that these blockages would provide any significant impact, I mentioned there was also a grill that may or may not have been in place when the sub was measured.

As far as I'm concerned, the whole grill debate isn't even that important although I'm certain it has at least some effect. The driver and the "ledge" were the elements I was trying to get him to simulate accurately, as it wasn't clear whether the grill was actually on or not during the measurement.

At this point, since I have no measurements of my own and couldn't find any reliably reputable measurements in a quick search (although there were a few that clearly show LF grill effects I'm not sure I trust them any more than the measurement that started this thread), I am going to back off (not concede) for now on the grill issue even though MTX seems to agree with me.

https://www.mtx.com/t/enclosure_constructionIf we were to place a grill over the vent, the tuning of the vent would change ...

I am still adamant that the driver and "ledge" are significant if an accurate sim is desired.

And I agree there is a big difference between the DSL "stub" and "cone correction".

Last edited:

If possible could you kindly direct me on how to set it to 100%, thanks.Absolutely, although you'll probably find it's not effective unless you set it to 100 percent blockage.

Context -

This is from a much earlier conversation where Brian was trying to figure out why the 118 measurement did not match his quick and dirty sim. The sim was incredibly inaccurate and didn't account for a lot of things. The discrepancy between sim and measurement was just a few hz and I mentioned that the large driver and the "ledge" rounding the last bend were fairly significant factors when you are looking for a few hz discrepancy.

I've already pointed out to you that the impedance curve for the TH118 suggests that some sort of internal damping is playing a considerable factor, and that could account for the most of the shift downwards in Fb that's needed to bring the sim that's based on the layout and the actual measurements into alignment.

But feel free to continue parroting on with your nonsense about "incredibly inaccurate sims" and the like, if it makes you happy. With that grille nonsense you have neatly exposed your degree of sciolism on the subject matter being discussed.

More data less wank

Why do you keep pushing discussion of a commercial design on DIY Audio? 😡

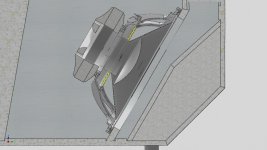

Anyhoo, here is another layout method for "correcting" that is also highly effective:

😕 If it's so obvious to you that the "ledge" is a bad idea why would you assume that Tom would have it made that way? To my knowledge this so called "ledge" is pretty much non-existent.I am still adamant that the driver and "ledge" are significant if an accurate sim is desired.

Why do you keep pushing discussion of a commercial design on DIY Audio? 😡

Anyhoo, here is another layout method for "correcting" that is also highly effective:

Attachments

The layout of the TH115/8 suggests however that there's a lot more than "cone compensation" going on. The amount of "compensation" seems to be 2 to 3 times the amount actually required. This suggests that there's another purpose to it.

Circling back to this statement I made, I think it's possible that the Danley designs go way past what seems to be needed for cone compensation, in order to improve the response at the upper end of the response curve and perhaps widen the horn's usable bandwidth. Basically taking the benefits of cone compensation and pushing them even further.

The results of a HornResp sim I did today suggest that you can accomplish this by significantly pinching in the CSA @ S2 ("The Infinia Pinch"? 🙂). In the FR graph pictured below, I've highlighted the major change in performance that was achieved by adding the "pinch" to the sim.

The sim is a single-expansion TH rather than the dual-expansion one, but I don't see why the same approach should not work in the latter, the only issue being that it cannot be sim'd in HornResp.

There's a possible disadvantage to this method however - the compression @S2 may be way over what's considered to be safe. If compression @S2 is a factor, there are other methods of accomplishing the same thing that are safer (including my DFD which sadly also cannot be sim'd in HornResp). However, if you are trying to keep the size of the TH down and also extend its response, and if you think your driver can handle the higher compression, it might be worth exploring. It's interesting enough for me to be tempted to try it out on my POC1 to see what the measured results would be like, but unfortunately my DFD is permanently installed in it already.

If any of you have a THAM12 or THAM15 build, the pinch might work well in that to reduce the notch at the upper end of the THAM's passband.

Attachments

I've already pointed out to you that the impedance curve for the TH118 suggests that some sort of internal damping is playing a considerable factor, and that could account for the most of the shift downwards in Fb that's needed to bring the sim that's based on the layout and the actual measurements into alignment.

But feel free to continue parroting on with your nonsense about "incredibly inaccurate sims" and the like, if it makes you happy. With that grille nonsense you have neatly exposed your degree of sciolism on the subject matter being discussed.

Just because I don't have proof right at the moment doesn't mean I'm wrong. If you have any proof, post it up.

Your laughably inaccurate sim doesn't make me happy, not sure why you would think it does. Stuffing may or may not be a factor, as we have discussed. That doesn't negate the fact that you STILL need to do an accurate sim of all the internal details if you want a sim to match a measurement. As I mentioned, it would take about a metric ton of stuffing to make up the discrepancy you were seeing between your sim and the measurement. Even if there is stuffing in there, your sim is incomplete.

Last edited:

😕 If it's so obvious to you that the "ledge" is a bad idea why would you assume that Tom would have it made that way? To my knowledge this so called "ledge" is pretty much non-existent.

Why do you keep pushing discussion of a commercial design on DIY Audio? 😡

Anyhoo, here is another layout method for "correcting" that is also highly effective:

Who said the "ledge" is a bad idea? I just said it needs to be accounted for in the sim or the sim won't be accurate. The "ledge" as shown in the picture, restricts the line by at least a couple hundred sq cm at that point, that's not non-existant.

I'm not pushing discussion of a commercial design. I didn't start the thread that originated this discussion, Brian was trying to reverse engineer the design and doing a very bad job of it. I was trying to help him figure out why his sim didn't match the measurement on DSL's site.

Just because I don't have proof right at the moment doesn't mean I'm wrong.

Hmm... so you think Art is wrong on the subject? Because the both of you can't be right concerning the grille issue. Seeing that Art designs, builds, measures and uses THs, and has been in the business for years, I think I'll go with what he has to say on the matter😉

Your laughably inaccurate sim doesn't make me happy,

..however your laughable attempts at rescuing what's left of your dignity after that grille fiasco are making me chuckle 😉

Art said it doesn't act like a solid block of wood (which btw, I never said it does), he didn't say it have no effect whatsoever. It does.

Chuckle all you like, speaking of not understanding the topic at hand, even the guy that says he invented "cone correction" doesn't agree with your redefinition of it.

And if you want to use Art as a tool to win arguments, how do you explain the fact that he doesn't agree with your redefinition of "cone correction" to include DSL's "stub" designs either? Even Neo Dan's drawings show "cone correction" directly in front of the cone. By my count, nobody agrees with your revised definition of "cone correction".

Not sure why you are trying so hard to make this personal, but whatever floats your boat. Technical arguments go a lot further though.

Chuckle all you like, speaking of not understanding the topic at hand, even the guy that says he invented "cone correction" doesn't agree with your redefinition of it.

And if you want to use Art as a tool to win arguments, how do you explain the fact that he doesn't agree with your redefinition of "cone correction" to include DSL's "stub" designs either? Even Neo Dan's drawings show "cone correction" directly in front of the cone. By my count, nobody agrees with your revised definition of "cone correction".

Not sure why you are trying so hard to make this personal, but whatever floats your boat. Technical arguments go a lot further though.

Last edited:

Art said it doesn't act like a solid block of wood (which btw, I never said it does), he didn't say it have no effect whatsoever. It does. It does have an effect, and my dignity is well intact.

LOL - clearly you missed this from his post: "I agree with Brian that your assessment of 50% closed grill on a tapped horn is ridiculous."

You are the equivalent of the emperor, having had it pointed out to him that he's wearing no clothes, still insisting that he's wearing the latest fashion, LOL.

And BTW, I DID previously indicate that that appears to be a lot more going on in the TH115/8 design than "cone correction", something you are also clearly choosing to overlook. See post #49 for a refresher. Also post #18.

Last edited:

Circling back to this statement I made, I think it's possible that the Danley designs go way past what seems to be needed for cone compensation, in order to improve the response at the upper end of the response curve and perhaps widen the horn's usable bandwidth. Basically taking the benefits of cone compensation and pushing them even further.

The results of a HornResp sim I did today suggest that you can accomplish this by significantly pinching in the CSA @ S2 ("The Infinia Pinch"? 🙂). In the FR graph pictured below, I've highlighted the major change in performance that was achieved by adding the "pinch" to the sim.

For clarification purposes, the example I provided is NOT a sim of the TH115 or TH118! It's just a quick sample sim that I put together to show what the impact of the pinch could be on a TH's response.

Ignoring the back and forth banter for a moment (though I like differences in thinking and standing up for once convictions, if respectfully so).

Has anyone tried this in IRL on any of the THAM series designs? or other designs and measured any difference in response before/after?

It seems promising from a theoretical point of view, and as for the compression increase it might be worth it, in the case of the THAM designs I do not think it would pose any grater risk since they all have plenty of room cone side.

I would have done this myself had I not presently been an apartment dweller, it's been up a couple of times in various forms and should to my mind be taken seriously, the cone compensation that is, not my current state of living 🙂

Thanks for posting this (also in the THAM15 thread).

Has anyone tried this in IRL on any of the THAM series designs? or other designs and measured any difference in response before/after?

It seems promising from a theoretical point of view, and as for the compression increase it might be worth it, in the case of the THAM designs I do not think it would pose any grater risk since they all have plenty of room cone side.

I would have done this myself had I not presently been an apartment dweller, it's been up a couple of times in various forms and should to my mind be taken seriously, the cone compensation that is, not my current state of living 🙂

Thanks for posting this (also in the THAM15 thread).

Ignoring the back and forth banter for a moment (though I like differences in thinking and standing up for once convictions, if respectfully so).

Has anyone tried this in IRL on any of the THAM series designs? or other designs and measured any difference in response before/after?

It seems promising from a theoretical point of view, and as for the compression increase it might be worth it, in the case of the THAM designs I do not think it would pose any grater risk since they all have plenty of room cone side.

I would have done this myself had I not presently been an apartment dweller, it's been up a couple of times in various forms and should to my mind be taken seriously, the cone compensation that is, not my current state of living 🙂

Thanks for posting this (also in the THAM15 thread).

No probs 🙂

I took the original HornResp parameters you provided, corrected them (by changing the expansion to Par and adding in a value in Vtc that's an approximate value for the volume of air sitting in front of the cone and in the driver cutout). I then converted the model to an S1-S5 version, and then pinched the CSA at S2 in that model down to 121 cm^2. The results look promising - see attached image.

This goes beyond "cone compensation" though, which IMO is just ensuring that the TH layout takes into consideration the volume of air contained in front of the driver's cone. We're actually significantly pinching in the CSA at S2 - see second image - quite a bit more than what would be required for cone compensation. The change in layout will look similar, but it's not the same.

Attachments

LOL - clearly you missed this from his post: "I agree with Brian that your assessment of 50% closed grill on a tapped horn is ridiculous."

You are the equivalent of the emperor, having had it pointed out to him that he's wearing no clothes, still insisting that he's wearing the latest fashion, LOL.

I didn't miss anything. He disagreed with my statement that it would be "dramatically different" with and without grill. Perhaps we just disagree on what constitutes "dramatic". If a sim doesn't match a measurement that's enough for me. The grill will have an effect, maybe not like a solid block of wood, but it will have an effect when placed over a port or horn mouth.

And BTW, I DID previously indicate that that appears to be a lot more going on in the TH115/8 design than "cone correction", something you are also clearly choosing to overlook. See post #49 for a refresher. Also post #18.

Yes you did and there is, the part you are overlooking is there is no "cone correction". The cone holes are not filled in in any of the dual driver DSL designs.

For clarification purposes, the example I provided is NOT a sim of the TH115 or TH118! It's just a quick sample sim that I put together to show what the impact of the pinch could be on a TH's response.

Not this example, but this isn't the one I was talking about, I was referring to the one in the previous conversation when you were trying to reverse engineer the DSL design.

Seriously, this is just about enough, we are not going to start agreeing with each other. Quit trying to make this personal and I'll just leave. For the most part I agree with almost everything you have to say on every subject. It's just the 118 sim from earlier and this "cone correction" mess I have issue with, that's all. In every other area I have a generous amount of respect for you and your work. On the other hand, you've called me stupid in different ways at least 3 times here and you know very well I'm not stupid. You've called my simulation abilities into question, even though I'm the one guy that ALWAYS say accurate sims match measurements, and you've seen at least a few dozen very accurate sims from me if you've been following along through the years. Just keep it technical, not personal, and I'll move on out of your way and you can discuss whatever you like.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Subwoofers

- "cone compensation" - a test case