I tried DEQX and I experienced some of the same drawbacks as with behringer. They can optimize the frequency curve, so that it looks straight as a stick. But the sound is compromized severely hereby. It sound like dynamics are pulled out of the music and that a blanket has been put in front of the speakers. My theory is that a DSP is a great tool, but to much/wrong processing i equally bad. Most good sounding active solutions I've heard, has been with groundsound. And I've heard at least 10 very different solutions with groundsound now. They all sounded different because of the room, the speakers and the way the DIY-guy chose to adjust the filter in the DSP. But the filter itself made no notice of itself - and I think that is the way a DSP filter should be.

There is also another thing about some DSP solutions. For example DEQX does not show how a current filter is optained. There is simply some "magic" going on in the box and then that's it. I would always use a DSP that allows you to see precisely what is is going on with filter slopes, filter types, Q-values and so on.

There is also another thing about some DSP solutions. For example DEQX does not show how a current filter is optained. There is simply some "magic" going on in the box and then that's it. I would always use a DSP that allows you to see precisely what is is going on with filter slopes, filter types, Q-values and so on.

Spot on!

I just want to add that, although I endorsed the use of DSP crossovers (and active crossovers, by extension), I don't think that this particular project is necessarily in need of it.

I just want to add that, although I endorsed the use of DSP crossovers (and active crossovers, by extension), I don't think that this particular project is necessarily in need of it.

I tried DEQX and I experienced some of the same drawbacks as with behringer. They can optimize the frequency curve, so that it looks straight as a stick. But the sound is compromized severely hereby. It sound like dynamics are pulled out of the music and that a blanket has been put in front of the speakers. My theory is that a DSP is a great tool, but to much/wrong processing i equally bad. Most good sounding active solutions I've heard, has been with groundsound. And I've heard at least 10 very different solutions with groundsound now. They all sounded different because of the room, the speakers and the way the DIY-guy chose to adjust the filter in the DSP. But the filter itself made no notice of itself - and I think that is the way a DSP filter should be.

There is also another thing about some DSP solutions. For example DEQX does not show how a current filter is optained. There is simply some "magic" going on in the box and then that's it. I would always use a DSP that allows you to see precisely what is is going on with filter slopes, filter types, Q-values and so on.

Last edited:

Spot on!

I just want to add that, although I endorsed the use of DSP crossovers (and active crossovers, by extension), I don't think that this particular project is necessarily in need of it.

May be. But that was not my point. I just wanted to add, that I did not think that the DEQX that Art Vandelay had a look at, was a worthy DSP for any such project, if you want optimum sound qaulity IMO. But they could have improved with a newer version and so on. But the DCN23 you mentioned, is indeed alot cheeper and have superior sound quality compared to the DEQX in my experience - that is all 🙂

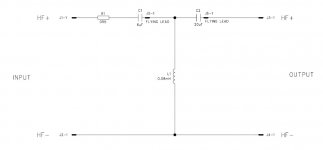

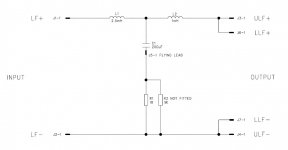

Looking at the crossover, they definitely haven't skimped on quality though. I doubt that I could buy those components for under $1000 per channel, so I'm inclined to think that the design engineer is a fan of the KISS principle.

Using a higher viscosity ferro fluid in the tweeter would have damped its impedance better and made the simple 1 cap filter function in a more ideal manor.

I've optimized the correction a little further since the last plot but I can say with full confidence that I prefer the treble now with it installed, and surprisingly the mids appear to be more transparent too, which is an added bonus.

I would say that the treble is slightly smoother and sweeter than before, and the mids have a more bell-like clarity and focus. The soundstage is more 3D and better defined than I've heard previously too, so there are definitely no downsides at all.

That is good to hear, although I have to say I am not surprised, tweeters rarely function correctly in an optimal way with a single cap filter, especially if their resonance isn't well controlled.

I recommend the use of a DSP active crossover highly. There are a handful to choose from, with MiniDSP (a few models) being the most popular. I personally use the Najda DSP which was developed by a member here. It is a well-spec'ed product, and it includes both analogue and digital inputs, as well as analogue volume control. Some info is available here:

A DSP that uses an analogue volume control after the DAC stage is mandatory imo for the best performance. This is even more important if you are using drivers of vastly different sensitivities or need to apply copious amounts of EQ to something like a sub. Level matching purely in the digital domain will lead to signal degradation.

My main gripe with these off the shelf DSP units (besides most not having an analogue volume control is a) clocking and b) the DACs they use. Most use a multichannel DAC of less than the best quality. Someone needs to release a DSP using the ES9018 in multichannel mode using its jitter removal, then you'd be really talking.

In the other end though, if the bi-wire is done properly with identical monoblocks and same cables throughout, this will lower distortion and offer a far superior great dynamics.

If the cables and amplifiers are properly specified then it wont make an iota of difference. Dynamics come from an amplifiers ability to deliver the required amount of current and to be able to swing the required number of volts to drive the loudspeaker without clipping. If it can do this then you've got no problem, if it cannot then you need a better amplifier, not necessarily bi-amping.

And lets be clear on this bi-wiring and bi-amping are two entirely different things. Bi-wiring is simply running two lots of wire from a single amplifier channel to the twin sets of binding posts on the loudspeakers. Bi-amping is using one channel of amplification for both sets of terminals, even if the crossover is still passive.

There is no point to bi-wiring whatsoever, unless you're using improperly chosen cables. And like I said above, there's no point in bi-amping either, unless you're amplifier isn't capable of driving the loudspeakers properly.

There are lots of poorly designed amplifiers out there in the hifi world too, not just loudspeakers!

For now I feel I would be happy to take a step at a time by going to passive bi-amping.

A properly designed PLLXO (parallel line-level x-over) would be great for the crossover between the FST and the bass section of the B&Ws, but I would stick with a passive between the FST and the tweeter.

Interesting measurements, do you guys want to comment on these?

Revel Ultima Salon2 loudspeaker Measurements | Stereophile.com

The ultima measures really well except for the way the tweeter behaves above 10k. This, just like Arts says, will result in the speaker losing air and sparkle. It's odd that is behaves like this. Revel are using a shallow wave guide with a standard 1" dome tweeter and the on axis response is ruler flat, but it loses output quicker than a standard 1" dome off axis.

I'd imagine Revels newer designs, that use a different tweeter and wave-guide would probably go a decent way to fixing thing.

Revel Performa3 F208 loudspeaker | Stereophile.com

For example.

I am having a little problem...not sure Art or someone else here can be of help.

On my 800 the rubber gasket behind the woofer was not placed exceptionally well so it always kind of bugged me and I always wanted to dress it properly...so today I tried to remove the midrange to get access to it.

Well it is barely impossible to remove the back plug in the back.

I have looked at the youtube video from B&W and they show how to do it on the Diamond 800 and basically they turn the back screw in the back with a large coin.

In my case I basically wore down the aluminum ridge on the plug trying to turn it...and my finger still hurts.

Though I have applied a ton of pressure it seems like when I release the screw it turns back the other way as if there was a tight o-ring pushing back or something.

I swore left and right but I was unable to remove it.

At this point since the back screw is wore down I want to replace it and still dress the rubber gasket properly around the midrange, but it I am really unable to take it off.

I have researched on internet but nobody seemed to have had the same problem so I don't know how to overcome this issue.

Another thing I found though...and might be useful to Art and other 800 users is that the screw in the back should be untightened and then tweaked to the right torque as this will have a large impact on the soundstage and sound quality overall. I think this is kind of stupid.

Basically B&W over tightens it for shipping then it needs to be loosen up after the speaker has been set up!

Anyway..any input will be largely appreciated. 😕

Thanks 😎

On my 800 the rubber gasket behind the woofer was not placed exceptionally well so it always kind of bugged me and I always wanted to dress it properly...so today I tried to remove the midrange to get access to it.

Well it is barely impossible to remove the back plug in the back.

I have looked at the youtube video from B&W and they show how to do it on the Diamond 800 and basically they turn the back screw in the back with a large coin.

In my case I basically wore down the aluminum ridge on the plug trying to turn it...and my finger still hurts.

Though I have applied a ton of pressure it seems like when I release the screw it turns back the other way as if there was a tight o-ring pushing back or something.

I swore left and right but I was unable to remove it.

At this point since the back screw is wore down I want to replace it and still dress the rubber gasket properly around the midrange, but it I am really unable to take it off.

I have researched on internet but nobody seemed to have had the same problem so I don't know how to overcome this issue.

Another thing I found though...and might be useful to Art and other 800 users is that the screw in the back should be untightened and then tweaked to the right torque as this will have a large impact on the soundstage and sound quality overall. I think this is kind of stupid.

Basically B&W over tightens it for shipping then it needs to be loosen up after the speaker has been set up!

Anyway..any input will be largely appreciated. 😕

Thanks 😎

I am having a little problem...not sure Art or someone else here can be of help.

On my 800 the rubber gasket behind the woofer was not placed exceptionally well so it always kind of bugged me and I always wanted to dress it properly...so today I tried to remove the midrange to get access to it.

Well it is barely impossible to remove the back plug in the back.

I have looked at the youtube video from B&W and they show how to do it on the Diamond 800 and basically they turn the back screw in the back with a large coin.

In my case I basically wore down the aluminum ridge on the plug trying to turn it...and my finger still hurts.

Though I have applied a ton of pressure it seems like when I release the screw it turns back the other way as if there was a tight o-ring pushing back or something.

I swore left and right but I was unable to remove it.

At this point since the back screw is wore down I want to replace it and still dress the rubber gasket properly around the midrange, but it I am really unable to take it off.

I have researched on internet but nobody seemed to have had the same problem so I don't know how to overcome this issue.

Another thing I found though...and might be useful to Art and other 800 users is that the screw in the back should be untightened and then tweaked to the right torque as this will have a large impact on the soundstage and sound quality overall. I think this is kind of stupid.

Basically B&W over tightens it for shipping then it needs to be loosen up after the speaker has been set up!

Anyway..any input will be largely appreciated. 😕

Thanks 😎

Fwiw, I have exactly the same issue with one of my speaker's FST. The large locking screw doesn't unlock and wants to spring back to the existing position. I'm not sure to what extent this would (or could) affect actual sound quality, noting that there's no real mention of it in the owners manual, but I haven't attempted to apply force for fear of damaging the slot. There's surely a B&W tool that's designed to fit the slot without damaging it and it would definitely be nice to get hold of one.

Art...thanks for your reply it is really comforting me to know I am not the only one with this problem. I have researched all over but I could not find anybody with this problem nor any mention on how to fix it. Yes, don’t put overpressure or you end up like me scuffing it (though the replacement part is very cheap…if I could get that out I will replace it)

If you research though on the tension/torque for that screw you will find that a lot of people that have tried to adjust it and found it to have a huge difference on soundstage and much clearer sound.

Basically if you read on B&W docs they tell you not to touch that because it is preset by factory and has significant impact. On other documentation it tells you instead that it comes overnighted for shipping but then you have to re-adjust it. I would definitely play with that if I could unlock it.

Let me understand better….on one of your speakers it comes out easily while on another one it doesn’t and it’s like mine that it springs back or on both of your speakers you have the same?

I also tried to call the customer service but obviously nobody ever answers.

I have sent this email (which I am posting here so you can read it too) see what and if they answer what they have to say to that:

---------------------------------------------------------------------

Hello,

I have just left a voicemail with my phone number and I decided to also send an email for reference.

I am trying to remove the midrange from my Signature800 because I wanted to dress out properly the rubber gasket that is around the driver which is not placed evenly from the factory I assume.

I have followed the instruction video for the midrange replacement shown on this website.

Nevertheless, I am completely unable to unscrew the drawbar fixing on mine. I tried to apply a lot of pressure with a big coin (as well as other tools I found to be more suitable), but once I remove the coin it seems to naturally turn back the other way with a sort of spring effect.

Now the ridge on the drawbar is significantly worn so once I put it back it needs to be replaced with a new one.

I am confident there must be a different way to remove the midrange that is different from the Diamond apparently and I am missing something out on this procedure.

I googled and checked on your website, but I was unable to find any related information! Could you please help me out?

Beside this I have 3 questions for you, if you can be so kind to answer I would really appreciate:

1) the drawbar fixing torque: other people have found this to impact significantly the overall sound. Does B&W have a proper torque wrench to being able to uncrew and set properly the drawbar without leaving any scuff or mark on it and set proper tension for the elastometer?

2) Would I be able to use the midrange and woofer parts from the latest diamond series instead and would there be any benefit by replacing those parts on my signature 800?

3) I happened to check the screws on the woofers and they were very loose, so I took the liberty to reasonably tightened those up. Is there a specific torque spec for these screws to follow or they have to be just reasonably tight?

Thanks for your attention.

Await your prompt response.

Best Regards,

Stefano.

If you research though on the tension/torque for that screw you will find that a lot of people that have tried to adjust it and found it to have a huge difference on soundstage and much clearer sound.

Basically if you read on B&W docs they tell you not to touch that because it is preset by factory and has significant impact. On other documentation it tells you instead that it comes overnighted for shipping but then you have to re-adjust it. I would definitely play with that if I could unlock it.

Let me understand better….on one of your speakers it comes out easily while on another one it doesn’t and it’s like mine that it springs back or on both of your speakers you have the same?

I also tried to call the customer service but obviously nobody ever answers.

I have sent this email (which I am posting here so you can read it too) see what and if they answer what they have to say to that:

---------------------------------------------------------------------

Hello,

I have just left a voicemail with my phone number and I decided to also send an email for reference.

I am trying to remove the midrange from my Signature800 because I wanted to dress out properly the rubber gasket that is around the driver which is not placed evenly from the factory I assume.

I have followed the instruction video for the midrange replacement shown on this website.

Nevertheless, I am completely unable to unscrew the drawbar fixing on mine. I tried to apply a lot of pressure with a big coin (as well as other tools I found to be more suitable), but once I remove the coin it seems to naturally turn back the other way with a sort of spring effect.

Now the ridge on the drawbar is significantly worn so once I put it back it needs to be replaced with a new one.

I am confident there must be a different way to remove the midrange that is different from the Diamond apparently and I am missing something out on this procedure.

I googled and checked on your website, but I was unable to find any related information! Could you please help me out?

Beside this I have 3 questions for you, if you can be so kind to answer I would really appreciate:

1) the drawbar fixing torque: other people have found this to impact significantly the overall sound. Does B&W have a proper torque wrench to being able to uncrew and set properly the drawbar without leaving any scuff or mark on it and set proper tension for the elastometer?

2) Would I be able to use the midrange and woofer parts from the latest diamond series instead and would there be any benefit by replacing those parts on my signature 800?

3) I happened to check the screws on the woofers and they were very loose, so I took the liberty to reasonably tightened those up. Is there a specific torque spec for these screws to follow or they have to be just reasonably tight?

Thanks for your attention.

Await your prompt response.

Best Regards,

Stefano.

regarding the crossover on the Signature I have posted yesterday...I haven't checked into the capacitors that are currently used on the crossover but I highly doubt it will be silver gold oil by Mundorf...especially considering they have 20uF and 47uF (not to mention the 100uF on the lower drivers) which are way to big of a value to have these nice silver gold oil by Mundorf.

My stupid question is: can the XO be redesigned to use smaller caps values perhaps bigger inductors so that better quality caps can be used?

I think 5th was interested in redesign it, if I would redesign it I would do it with using in mind small cap values to have better quality parts. Is that a possibility or not?

My stupid question is: can the XO be redesigned to use smaller caps values perhaps bigger inductors so that better quality caps can be used?

I think 5th was interested in redesign it, if I would redesign it I would do it with using in mind small cap values to have better quality parts. Is that a possibility or not?

regarding the crossover on the Signature I have posted yesterday...I haven't checked into the capacitors that are currently used on the crossover but I highly doubt it will be silver gold oil by Mundorf...especially considering they have 20uF and 47uF (not to mention the 100uF on the lower drivers) which are way to big of a value to have these nice silver gold oil by Mundorf.

My stupid question is: can the XO be redesigned to use smaller caps values perhaps bigger inductors so that better quality caps can be used?

I think 5th was interested in redesign it, if I would redesign it I would do it with using in mind small cap values to have better quality parts. Is that a possibility or not?

I seem to recall a dealer telling me that the Sig versions did use Mundorf caps, which was one of the distinctions over the standard Nautilus series, but it's pretty easy to check. Simply lay one of the speakers down on its side and unscrew the crossover cover. I lay mine down on a baby mattress to prevent damaging the gloss finish, but I'm sure that pillows or cushions etc would work just as well. The screws are star headed so you'll need to find the right driver attachment too.

My stupid question is: can the XO be redesigned to use smaller caps values perhaps bigger inductors so that better quality caps can be used?

I think 5th was interested in redesign it, if I would redesign it I would do it with using in mind small cap values to have better quality parts. Is that a possibility or not?

The answer to this is no btw.

You'll need to use specific values for the 3rd order Butterworth filter that's used. And yes, those caps will be quite large.

Yes I knew the same thing i.e. signature uses mundorf caps. As soon as I figure out how to unscrew the back port out I will move onto opening the crossover to check.

Nevertheless, I still think the XO can be done better at least with regard to part use. If someone wanted to maintain all the cut offs and slopes, couldn't the filter be tweaked with to use lower cap values? Is that possible?

I also still think that the idea to try a redesign of the XO by 5th would be an interesting topic.

Nevertheless, I still think the XO can be done better at least with regard to part use. If someone wanted to maintain all the cut offs and slopes, couldn't the filter be tweaked with to use lower cap values? Is that possible?

I also still think that the idea to try a redesign of the XO by 5th would be an interesting topic.

The answer to this is no btw.

You'll need to use specific values for the 3rd order Butterworth filter that's used. And yes, those caps will be quite large.

are you just referring to the highs or in general?

Why do other designers use lower cap values and end up using premium Dueland cast? Is that a matter of the driver's type or purely a design choice?

BTW B&W answered but their answer was pretty sloppy I will post it here shortly after this post.

here is their answer:

Stefano,

The Sig 800 midrange removal is exactly the same as the Nautilus, D and Diamond series speakers. the midrange needs to be firmly held in place and occasionally may need a large screw driver to be removed. If you have been unsuccessful then i would recommend bringing the unit to the dealer. if you are spinning the midrange you can cause damage to the wiring inside.

1) there is no exact torque once its snug the unit is fine it is designed to float in the rubber isolators. when the fixing is snug then there will be an air seal with the isolators but there is enough room for the mid to float in place.

2) Crossovers are designed to work with the original drivers so replacing drivers from a different model would degrade the sonic performance.

3) I do not have an exact spec for these but just keeping them snug and checking them every few years does not hurt.

Kind regards,

Mike

Bowers & Wilkins

------------------------------------------

To which I have answered:

Hi Mike,

The cut off frequency and crossover on the low driver on the Diamond is exactly the same as on my sig800 and I am wondering if the new material is better than mine.

My question is: provided I changed the different values on the board on the sig800 to match the values on the diamond, are the drivers on the diamonds actually an improvement over the one used on the signature version or not really and can they physically fit or the diamond has different cutouts for those divers on the cabinet?

Beside this, about the midrange issue, the driver is not spinning at all in the front, the screw is just very hard to turn and seems to spring back; taking the speaker to a dealer is not like bringing my other 805 I have. Loading the 800 is a pretty heavy task for taking a screw out. I don't understand what the dealer can do more for me. Do they have a specifically made tool for that?

If so, can I purchase it from B&W?

Thanks,

Stefano.

Stefano,

The Sig 800 midrange removal is exactly the same as the Nautilus, D and Diamond series speakers. the midrange needs to be firmly held in place and occasionally may need a large screw driver to be removed. If you have been unsuccessful then i would recommend bringing the unit to the dealer. if you are spinning the midrange you can cause damage to the wiring inside.

1) there is no exact torque once its snug the unit is fine it is designed to float in the rubber isolators. when the fixing is snug then there will be an air seal with the isolators but there is enough room for the mid to float in place.

2) Crossovers are designed to work with the original drivers so replacing drivers from a different model would degrade the sonic performance.

3) I do not have an exact spec for these but just keeping them snug and checking them every few years does not hurt.

Kind regards,

Mike

Bowers & Wilkins

------------------------------------------

To which I have answered:

Hi Mike,

The cut off frequency and crossover on the low driver on the Diamond is exactly the same as on my sig800 and I am wondering if the new material is better than mine.

My question is: provided I changed the different values on the board on the sig800 to match the values on the diamond, are the drivers on the diamonds actually an improvement over the one used on the signature version or not really and can they physically fit or the diamond has different cutouts for those divers on the cabinet?

Beside this, about the midrange issue, the driver is not spinning at all in the front, the screw is just very hard to turn and seems to spring back; taking the speaker to a dealer is not like bringing my other 805 I have. Loading the 800 is a pretty heavy task for taking a screw out. I don't understand what the dealer can do more for me. Do they have a specifically made tool for that?

If so, can I purchase it from B&W?

Thanks,

Stefano.

are you just referring to the highs or in general?

Why do other designers use lower cap values and end up using premium Dueland cast? Is that a matter of the driver's type or purely a design choice?

BTW B&W answered but their answer was pretty sloppy I will post it here shortly after this post.

The optimum values of 'C' will depend on the impedance of the driver and also the frequency response to some extent, as well as the crossover frequency of course. Crossing over at 4kHz is attractive from that point of view, and especially so if it's first or 2nd order, where only a single cap is required.

yes agreed, that second order with simple cap is really attractive,but it seemed not to work at least not with that diamond tweeter.

Regarding the 4KHz crossover I found it really effective and changing that IMHO is detrimental, thinking about the wideband and its benefit....or tannoys with their non crossover over audible band

Regarding the 4KHz crossover I found it really effective and changing that IMHO is detrimental, thinking about the wideband and its benefit....or tannoys with their non crossover over audible band

the screw is just very hard to turn and seems to spring back

This reminds me of a few occasions when I tightened a driver screw which had a thread long enough to protrude into the cabinet void. It caught onto some dacron fibre filling, which got twisted around the screw. I could not tighten it because the fibres were wound so tight and, on releasing the screw, the screw turned in the reverse direction

yes you might be right....not sure this is the case...but since there is not much going on there...it must be some rubber or something caught on the threads....I will acquire a wide screwdriver and pump it through....then clean up everything and replace the drawbar fixing with a new one...

I will say here that on my speakers, with the 800 series nautilus cabinet clones I use a long drawbar too, although mine is simply a very long threaded M6 rod. Half of the problem using that method is that the stuffing inside the speaker finds it very easy to start wrapping itself around the rod if you try to twist it, creating the issue that Shaun mentioned. If B&Ws drawbar is only threaded at the very ends then this wont happen inside the 800 cabinet, still if it is and B&W screws the drawbar in with the driver in place, rather than screwing the drawbar into the driver first, then inserting the driver + drawbar in together, then the stuffing inside could easily have become twisted around the rod during the initial installation.

wow....5th you have identified the problem right away! I bough a 25mm wider and nice chisel too which fits into the back drawbar fixing so I was able to remove it and upon inspection of the situation I found the problem to be exactly what you described it to be.

First of all the drawbar was loose so when I would twist the cap, the bar itself would twist around causing it to tangled up with the white insulation.

For Art: the problem with yours I am assuming is the same i.e. they didn't tight the bar on the woofer properly and given the insulation inside is pretty tight when you twist the back cap the bar is twisting thus getting caught like on mine.

I recommend you to buy the same simple tool I got and order a new back cap from B&W.

Power through and remove the midrange, tight the bar to the midrange,change the back fixing cap for aesthetic purposes and put everything back nicely.

At that point you will be able to play with the tension and see if, like other people say, it make a significant difference or not.

I am going to post some pictures after this.

First of all the drawbar was loose so when I would twist the cap, the bar itself would twist around causing it to tangled up with the white insulation.

For Art: the problem with yours I am assuming is the same i.e. they didn't tight the bar on the woofer properly and given the insulation inside is pretty tight when you twist the back cap the bar is twisting thus getting caught like on mine.

I recommend you to buy the same simple tool I got and order a new back cap from B&W.

Power through and remove the midrange, tight the bar to the midrange,change the back fixing cap for aesthetic purposes and put everything back nicely.

At that point you will be able to play with the tension and see if, like other people say, it make a significant difference or not.

I am going to post some pictures after this.

- Home

- Loudspeakers

- Multi-Way

- B&W Signature 800 upgrade diamond tweeter