Because I simply copied and pasted data from Volvotreter's spreadsheet. Rounding off as you have shown is too rough, you need 3 significant digits at least where the horn is very narrow as that has a big effect. So instead of 0.007 use 0.00708. If you must then 0.0071.

You can add more segments - just follow format I have and add more nodes.

You can add more segments - just follow format I have and add more nodes.

Hi

I have not did try with akabak nodes, etc etc, I get the hang of it now, no not the rope🙄

Drawn this digits on a wood with a pen with that precision I go try. I think I need a digital measure tool, but I have do it also in cm.

coming oke, the first attemt with vorm the horn has failed, to stiff so try option two very thin plywood in layers.

regards

I have not did try with akabak nodes, etc etc, I get the hang of it now, no not the rope🙄

Drawn this digits on a wood with a pen with that precision I go try. I think I need a digital measure tool, but I have do it also in cm.

coming oke, the first attemt with vorm the horn has failed, to stiff so try option two very thin plywood in layers.

regards

Try thin cardboard (non corrugated thick stock) then reinforce with resin or PVA impreganted burlap bags applied to back side.

In the old days they used to make model RC airplanes out of balsa wood. You know what they use now? Foam core sheets!

In the old days they used to make model RC airplanes out of balsa wood. You know what they use now? Foam core sheets!

Not all is available here, except very promising plywood special for bending, cardboard was just to thick, it snaps because of the bend of a tractrix, exponentional horn it work not her.

I have ready the table every 1 cm to make the bend marks. I have horn is 46.76 long 4.5 cm throat square mouth 1816 cm2.

regards

I have ready the table every 1 cm to make the bend marks. I have horn is 46.76 long 4.5 cm throat square mouth 1816 cm2.

regards

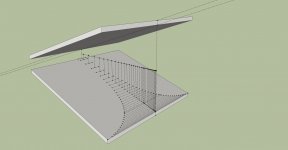

Wellllllll I have tryed in sketchup the outcome of the tractrix sheet from volvotreter, but I just did something wrong because I get no two sides who are conic and the width stractrix, tractrix I did see but the conic one is not conic.

Your horn has two sides who are conic, I have use the square output, yes it needs some practice I see, so it is not bad to do my own one to learn.

The distance steps from sheet has to be in center of horn I presume, and the output I have to devide x 2 to get proper horn otherwise I get strange things, So in the evening I go try again think I am right devide it..

regards

kees

Your horn has two sides who are conic, I have use the square output, yes it needs some practice I see, so it is not bad to do my own one to learn.

The distance steps from sheet has to be in center of horn I presume, and the output I have to devide x 2 to get proper horn otherwise I get strange things, So in the evening I go try again think I am right devide it..

regards

kees

You have to plot the spreadsheet output vs axial distance to see which side is straight linear and which side is curved. I recall that it is opposite of what you think, that is, the vertical dimension is curved and the horiz is straight. The axial distance is indeed centerline distance, not distance along the horn wall. You will figure it out...

Thanks I have it, just plot and I see what happens, I do this in sketchup so I have 3d.

Lot of work such a horn, a tapped horn is less complicated even the folding but horns are also new for me so i haev to get familiair with the calculations.

First I go put this in akabak, but I think I do not need to put there the whole 68 steps? or just a part of it but with mouth and throat in it I do not now what akabak does with that, but I go try, lot of fun this.

regards

kees

Lot of work such a horn, a tapped horn is less complicated even the folding but horns are also new for me so i haev to get familiair with the calculations.

First I go put this in akabak, but I think I do not need to put there the whole 68 steps? or just a part of it but with mouth and throat in it I do not now what akabak does with that, but I go try, lot of fun this.

regards

kees

Last edited:

That is why I suggested you simply scale my drawings. They were a pain in the behind to produce. Great that you are doing from scratch. Learn a lot that way.

You are doing all the right things and aaking all the right questions. I have no doubt your horn will work well and sound spectacular.

You are doing all the right things and aaking all the right questions. I have no doubt your horn will work well and sound spectacular.

It is exactly what you say, I go from scratch because I want to learn and also to see what happens, just draw the mouth make a center and go on with the stuff. also I do not like to take designs from others, yes I now it is diy audio but just then it is important to design and discover new things it is such fun.

First the akabak because mine is different, is shorter and wider as I can see.

I use 68 steps.

I go further watching laurel and hardy from the coutch with a beer. Tomorrow I try coming week I have the horn from wood if everything go well.

regards

First the akabak because mine is different, is shorter and wider as I can see.

I use 68 steps.

I go further watching laurel and hardy from the coutch with a beer. Tomorrow I try coming week I have the horn from wood if everything go well.

regards

You can't use 68 steps as akabak has max limit of 55 nodes. There won't be much difference after 20 or 25 steps.

I go to 25 steps like you advise, thanks for telling me because Otherwise I have do it for nothing and see how it coming out, if to much space between drawing the horn bend is difficult bu maybe you have a trick.

How do you get the horn in a nice bend when such little steps? it give some cm between steps where the horn needs precise bending /form. The conic part is not a problem a line bewteen mouth and throat will do? here is no bend otherwise it not get it made.

regards

kees

How do you get the horn in a nice bend when such little steps? it give some cm between steps where the horn needs precise bending /form. The conic part is not a problem a line bewteen mouth and throat will do? here is no bend otherwise it not get it made.

regards

kees

The foam core bends very nicely when you score little cuts on the concave side (many parallel line shallow cuts maybe 2mm deep spaced 5mm apart). Use round object to preform the curve by rolling the foam core after scoring to get the bend.

I want to go with plywood bend, it is special wood who can be bended but is more stiff so I need some more points to make the form, I have no foam here also, but we have that plywood who work fantastic I do glue some layers when the first one is dryed and in it,s form.

I go draw it first in sketchup so I can use that for making the horn, sketchup do work wel for precise measurements but has also it shortcomings.

I did read somewhere that there are more drw programs who work better but not autocad because this is a overbloated program in my eyes, several gigabytes for a draw program is very mucho.

This is a dutch link for the bendings plywood used for everthing what needs bending.

BUIGTRIPLEX buigplaat

regards

kees

I go draw it first in sketchup so I can use that for making the horn, sketchup do work wel for precise measurements but has also it shortcomings.

I did read somewhere that there are more drw programs who work better but not autocad because this is a overbloated program in my eyes, several gigabytes for a draw program is very mucho.

This is a dutch link for the bendings plywood used for everthing what needs bending.

BUIGTRIPLEX buigplaat

regards

kees

Hi

Now I understand why you say to me just use my design, it is a lot lot lot of work to draw it, special when more steps is used, in my case it is now 35 steps.

Further I did get wrong every time, until I discover I have to use always the same origine now things fits nicely.

I have to devide all the stuff but the conical part just mouth and throat.

regards

e

Now I understand why you say to me just use my design, it is a lot lot lot of work to draw it, special when more steps is used, in my case it is now 35 steps.

Further I did get wrong every time, until I discover I have to use always the same origine now things fits nicely.

I have to devide all the stuff but the conical part just mouth and throat.

regards

e

Kees,

That looks good but sure looks like it was a lot of work. What is the angle between the two flat walls?

That looks good but sure looks like it was a lot of work. What is the angle between the two flat walls?

Kees,

That looks good but sure looks like it was a lot of work. What is the angle between the two flat walls?

It was not as much work I did think, however sketchup is not really a good program to make horns, it is such a pain in the *** to move things or delete without get hollow walls.

Find a substitute for sketchup I go search for. If a program writer did write such drawn program for horns, special for horns it will be great.

Panels are 18 degree so far that I see, it is preciese with volvotreter program drawn. horn is shorter as yours 46.7 cm.

How width and high is your horn?

regards

I have done the rest also, now I can see how it works, it is more easy.

However sketchup is dificult sometimes to get things closed like the horn itselfs between the steps, sometimes it refuse to do so except when draw two extra lines in the middle. So if there is someone here to can explane me how I am very pleased.

I also try freecad maybe it is better. Sketchup is usable but you never now there is something better.

regards

kees

However sketchup is dificult sometimes to get things closed like the horn itselfs between the steps, sometimes it refuse to do so except when draw two extra lines in the middle. So if there is someone here to can explane me how I am very pleased.

I also try freecad maybe it is better. Sketchup is usable but you never now there is something better.

regards

kees

Attachments

Looks great Kees. You drawings remind me of my 3d model at this point too. I am just getting back from a long trip so should be back up to speed shortly.

- Home

- Loudspeakers

- Multi-Way

- Presenting the Trynergy - a full range tractrix synergy.