It might have been mentioned before, but where did you source the vee sapphire from?

Nigel,

I guess your phone number changed... the person I just text doesn't seem too keen on unipivot and open baffles... send me a PM or Text.

Nigel,

I guess your phone number changed... the person I just text doesn't seem too keen on unipivot and open baffles... send me a PM or Text.

Nevermind... I was messaging the wrong Nigel... Seems I lost your digits. PM me... 😀

Subscribing to the thread 🙂

I love the simplicity of the design.

My plan is to make the arm out of solid ebony measuring roughly 7x5x350mm which will weight around 16 grams ( going for the 306mm length, 13mm overhang, 293mm pivot to spindle with null points at 60,6mm and 128,5mm)

The "headshell" will actually be the tonearm body itself and the 7mm thickness should easily allow the cartridge to be mounted at the appropriate 18 degrees with just a small drilled cap, just like in the Altmann design.

The tonearm will be rectangle, and the counterweight will have to be split in two to allow balancing and azimuth adjustment.

Initial testing is going to be with a pen ball and a fuse cap, and if I like it I will move to a saphire and tunsten bearing.

I love the simplicity of the design.

My plan is to make the arm out of solid ebony measuring roughly 7x5x350mm which will weight around 16 grams ( going for the 306mm length, 13mm overhang, 293mm pivot to spindle with null points at 60,6mm and 128,5mm)

The "headshell" will actually be the tonearm body itself and the 7mm thickness should easily allow the cartridge to be mounted at the appropriate 18 degrees with just a small drilled cap, just like in the Altmann design.

The tonearm will be rectangle, and the counterweight will have to be split in two to allow balancing and azimuth adjustment.

Initial testing is going to be with a pen ball and a fuse cap, and if I like it I will move to a saphire and tunsten bearing.

Sounds promising Dimitri.

Please take photos down the road 🙂

It might just push me over the edge to create something more elaborate than what I have 🙂

Regards

Please take photos down the road 🙂

It might just push me over the edge to create something more elaborate than what I have 🙂

Regards

The thread continues to limp along...

...not much posted on this thread for some time.

I've been spending my time trying to get the fit and finnish to a level that folks may actually put out their hard-earned money for, and that they can have some pride of ownership in. So far the single largest issue is the arm cueing lever/mechanism.

I still feel much better about using a proper set screw for the female bearing vs. using a fuse end cap. At least this way it could be changed to a jewel Vee bearing cup easily enough as an upgrade if so desired. I really don't see the need to vary from a pen nib for the male bearing though.

...not much posted on this thread for some time.

I've been spending my time trying to get the fit and finnish to a level that folks may actually put out their hard-earned money for, and that they can have some pride of ownership in. So far the single largest issue is the arm cueing lever/mechanism.

I still feel much better about using a proper set screw for the female bearing vs. using a fuse end cap. At least this way it could be changed to a jewel Vee bearing cup easily enough as an upgrade if so desired. I really don't see the need to vary from a pen nib for the male bearing though.

For the cueing mechanism, are you looking for an oil damped one? Or just something to lift the arm?

How about something like what is usually used on Colin's linear arm?

http://www.diyaudio.com/forums/atta...761-diy-linear-tonearm-linear-tonearm-001.jpg

Just a rod that pushes the arm tube.

It can be used on the back pushing the arm down, or on the front pushing the arm up. Whatever fits your design best. And you don t even have to do it like in the photo. You can just do a lever with a single pivot to push the arm.

http://www.diyaudio.com/forums/atta...761-diy-linear-tonearm-linear-tonearm-001.jpg

Just a rod that pushes the arm tube.

It can be used on the back pushing the arm down, or on the front pushing the arm up. Whatever fits your design best. And you don t even have to do it like in the photo. You can just do a lever with a single pivot to push the arm.

...not much posted on this thread for some time.

So far the single largest issue is the arm cueing lever/mechanism.

I use my fingers, works everytime 😉

Regards

Why not to build something like Rega'a spring based lift. I have used it on my DIY Schroeder clone. It looks quite simple to build.

Regards

Sachin

Regards

Sachin

I rather keep it as simple as possible. Armlift/rest would be to peoples liking as it is not a part of the music reproduction. I have a rest but it is not part of the arm.

Regards

Regards

I ve lived with an RS-A1 for a while and I have to say that having no arm lift is a PITA for me...

Last edited:

I ve live with an RS-A1 for a while and I have to say that having no arm lift is a PITA for me...

So, design one. 🙂

Rega style arm lift

sachu ,

great to hear from you!(and I hope all is well with you and yours)

I looked at the Rega lift and it does look like it could be a possibility. I always "assumed" that an arm lift would be the easiest part. I have a Linn Akito II arm here that has a pretty simple lift as well. I'll look closer at that one. too.

sachu ,

great to hear from you!(and I hope all is well with you and yours)

I looked at the Rega lift and it does look like it could be a possibility. I always "assumed" that an arm lift would be the easiest part. I have a Linn Akito II arm here that has a pretty simple lift as well. I'll look closer at that one. too.

Look at the lift mechanism that is being used over in the linear tone arm thread. A good stiff wire and a pivot point is all you need.

Lift/Lower Device

Hi Folks

I've been very quiet on this thread recently-my work contract was terminated and I had a lot of other things to think about! However the new job starts on Monday (phew!!)

I'm offering three versions of my design of unipivot:

Regards

Chris

Hi Folks

I've been very quiet on this thread recently-my work contract was terminated and I had a lot of other things to think about! However the new job starts on Monday (phew!!)

I'm offering three versions of my design of unipivot:

- No lift/lower device

- My design which works very well. It's undamped but very easy to use and looks pretty good to me. No extra charge for this.

- A version with the genuine Rega lift/lower. This is expensive at a £25.00 premium but people seem to be prepared to pay as the total arm is extremely good value.

Regards

Chris

Attachments

I ve lived with an RS-A1 for a while and I have to say that having no arm lift is a PITA for me...

Hi Dimitri.

How does it proceed?

Regards

Hi Mark

I've used a variety of wire from cheap copper litz to Cardas. I have found that when you have a good design, this shines through even with the cheap stuff!

Regards

Chris

I've used a variety of wire from cheap copper litz to Cardas. I have found that when you have a good design, this shines through even with the cheap stuff!

Regards

Chris

Hi Dimitri.

How does it proceed?

Regards

I have cut the ebony, but had no time to work on it. I still have no idea how to attach the rotating/hanging weight and allow it to balance the azimuth on the rectangle arm body.

I will post some more stuff within the weekend.

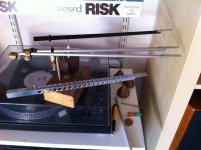

So let's prototype....

I started with a piece of carbonshaft of a golfclub, and ended with the question "how to make a headshell". Ok , use a piece of 10 mm alu tube, cut and sand it in shape en fix a small alu piece on it.

So done... then the question who don't use the alu tube as an arm...

And why not do the same with an 8mm alu tube...

And seeing an old Gray unipivot tonearm... why don't do something like that with some alu stuff lying here doing nothing.

So instead of one 2.19... it became an "8.76"

Next is an armbase, and a "twinpivot diy version"of the simplicity tonearm...

Mark

I started with a piece of carbonshaft of a golfclub, and ended with the question "how to make a headshell". Ok , use a piece of 10 mm alu tube, cut and sand it in shape en fix a small alu piece on it.

So done... then the question who don't use the alu tube as an arm...

And why not do the same with an 8mm alu tube...

And seeing an old Gray unipivot tonearm... why don't do something like that with some alu stuff lying here doing nothing.

So instead of one 2.19... it became an "8.76"

Next is an armbase, and a "twinpivot diy version"of the simplicity tonearm...

Mark

Attachments

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- my latest iteration of "Nanook's 219 tonearm"..