At first i thought you were building a spaceship, until i realised it was a speaker. Very ambitious and great work. So the question is, when is the group buy?! 😉

That could be a very real possibility if everything allows for it and the speaker is refined to a tee.

Yes I am writing this. I hope Remlab comments his original comments were the fire I needed to start.

A new system has been developed that will push me into the testing phase in which I will test and perfect the lamella as the first subject in my agenda should be fun

Very impressive.

I wonder if anyone has looked into using an accordion-roll type of radiator, formed like a "Chinese Lantern", rather than lamellas/petals:

Chinese Lantern making - The best Chinese lantern site

It seems like that might avoid the need for sealing between lamellas. There are probably some other issues with that, though (such as odd resonances).

Anyway, congratulations. That's way beyond the typical DIY effort.

I wonder if anyone has looked into using an accordion-roll type of radiator, formed like a "Chinese Lantern", rather than lamellas/petals:

Chinese Lantern making - The best Chinese lantern site

It seems like that might avoid the need for sealing between lamellas. There are probably some other issues with that, though (such as odd resonances).

Anyway, congratulations. That's way beyond the typical DIY effort.

"It seems like that might avoid the need for sealing between lamellas. There are probably some other issues with that, though (such as odd resonances)."

This construction technique can be useful for the sealing, but we need a pulsating sphere, so I think the lamellas will be still a must...

but it is a good idea nevertheless

This construction technique can be useful for the sealing, but we need a pulsating sphere, so I think the lamellas will be still a must...

but it is a good idea nevertheless

Member

Joined 2003

I wonder if anyone has looked into using an accordion-roll type of radiator, formed like a "Chinese Lantern"

On the PE forum, Neil Davis has mentioned working on a cylindrical AMT.

Thank you Bwaslo Alot of time and effort for sure. karellen do you have any updates on your model? I have seen some efforts towards cylindrical/odd shaped amt designs I dont think there was much after and couple of models but I forget which thread it is.

Thank you Bwaslo Alot of time and effort for sure. karellen do you have any updates on your model? I have seen some efforts towards cylindrical/odd shaped amt designs I dont think there was much after and couple of models but I forget which thread it is.

Sorry, no updates, still an armchair project...

But my two sons (1 1/2 and 3 years old) progress fine, absorbing all the resources available!

good luck and please, maintain us informed of the updates...

regards

Pedro

Will do karellan. The amount of variables for the lamella are high so testing and perfecting is going to take some serious effort. Other parts of the speaker of also part of the plan further down the line. There are some good ideas for sealing and such.

The testing stage is officially here all problems that hindered me in making a very accurate, reliable, and fast speaker have been solved. This New build will be a test of all of this after that changes in materials and construction will be tested and results will be shown here along with a recording.

Thank you Karellan. The process is working great although I did find a few kinks that werent anticipated in real life assembly. This will no doubt be the best most accurate assembly. The first few test will show a difference within the same mid-range unit. changes in "additions" that will will show a before and after effect. The ones after will be a whole other mid-range with a design that should increase sensitivity.

Build

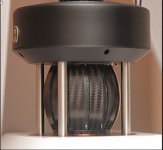

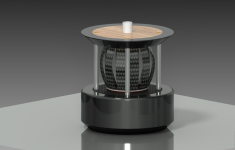

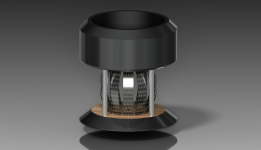

Further along the build Almost ready for a listen. Could it fool you?

Further along the build Almost ready for a listen. Could it fool you?

Attachments

Last edited:

The seal between lamelas looks very good

Very good craftmanship.

How it is done? Some kind of EVA?

Very good craftmanship.

How it is done? Some kind of EVA?

Thank you karellan the amount of craftsmanship needed is insane. The amount of research and development needed to make a system to allow for the perfect alignment of all elements far exceeds it. No it is not EVA. It is in fact Neoprene foam. There are several tricks in building this thing that one only will truly know if they build it and research the heck out of it. The actual alignment system I use is in my opinion a little more "correct" than mbl. All from what I seen tells me they may be a little out of plumb so to speak.

Last edited:

Very nice build quality.

Did you test each petal for equal tension under compression?

I would think any deviation would cause the coil to rock if they were not equal.

Regards

David

Did you test each petal for equal tension under compression?

I would think any deviation would cause the coil to rock if they were not equal.

Regards

David

Testing at every stage is crucial to know you will not end up with a messed up speaker. The most important thing to get all of the lamellas right and have to proper know how and equipment to place them. After that its simply a matter of careful hands. The speaker is finished there is a lag to when I post. Speaker has no apparent rock modes. only clean sound.

Last edited:

- Home

- Loudspeakers

- Planars & Exotics

- Summer Project - Replication of MBL loudspeaker 101mkII