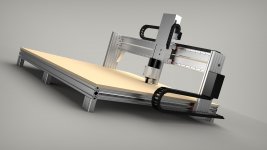

Looks really nice. I'll be interested to hear your experience with the enclosure. My biggest problem currently is that my machine blows sawdust all over my garage. It keeps me from using it as much as I'd like because it's so annoying. I've been thinking about making an enclosure for a while.

Hi John

The dust problems are a nasty business - both health and clean up time. So if this is a concern then I'd recommend an enclosure as a matter of course. At the very least it confines all the mess to one small area and when used in conjunction with a good dust shoe it'll pretty much eliminate the need for any clean up after a job.

If the enclosure isn't an option and what you mostly cut is 2D from sheet stock then it would be worth the time to DIY yourself one of these:

CNC Router Pressure Foot - YouTube

Very effective but obviously, like most dust shoes, its useless for 3D!

I have a dust shoe I made, but as you say it only helps for flat stock jobs. I do a mix of 2d and 3d. I've been thinking of hooking up a dust collector to the bottom of the enclosure as well as to the dust shoe to try to keep a slight negative pressure inside the enclosure to really keep the dust inside.

In that case John I'd definitely look into the enclosure as a measure to stop the dust spreading out around your workspace. At least that way for 3D work you'll have a relatively easy clean up of dust the shoe doesn't catch. That's pretty much where I've resigned myself too. If I find something that works better I'll be sure to post back on here.

CNC Router Pressure Foot - YouTube

Very effective but obviously, like most dust shoes, its useless for 3D!

I like it - but then it'd be catastrophic if you have any clamps or bolts holding down your material.

I made a shoe out of an old broom:

It's surprisingly good at stopping dust spraying about with some fairly deep objects (maybe 3cm thick), and is happy with clamps, though granted any 'proper' 3D cutting would defeat it.

I'd actually like to get an enclosure such that I probably wouldn't then bother with a dust extractor + foot during cutting jobs. As long as the dust doesn't pile up too bad, it's quieter, cheaper, and less hassle to just clean the dust up at the end of the job.

As for lung protection, I bought one of these http://www.trend-uk.com/en/UK/product/AIR_PRO/4/178/airshield_pro_respirator_230v_uk_.html a while back and I absolutely swear by it now - several hours of MDF dust and no problems at all (I usually end up with flu like symptoms as I've obviously become pretty sensitised to it). Wish I'd bought one years ago.

Video of Z axis working with the new parts and electronics.

Z Axis with Leadshine AM882 Drives - YouTube

Z Axis with Leadshine AM882 Drives - YouTube

Video of Z axis working with the new parts and electronics.

Z Axis with Leadshine AM882 Drives - YouTube

It's ALIVE! 🙂

..man, read through the your mycncuk thread, depressing. 🙁

You really hope that a Co. "steps-up", but sadly it's a rarity.

Then there is just the enormous missed-opportunity. i.e. produce a better product, garner critical acclaim, and become very profitable as a result. Idiots - from potential Hero, to Zero.

Then there is just the enormous missed-opportunity. i.e. produce a better product, garner critical acclaim, and become very profitable as a result. Idiots - from potential Hero, to Zero.

That's just the thing. Hard to believe really. I've been trying to fix the issues for so many months now but really there's a point where you just say enough is enough.

Its slowed me down massively and on top of that there have been other issues to deal with too. 2012 - not one of my better years so far! 😀

Last edited:

Homing switches now configured and working. Only the Z axis functional at the moment but I'm happy with the result.

Z Axis Homing - YouTube

Z Axis Homing - YouTube

Homing switches now configured and working. Only the Z axis functional at the moment but I'm happy with the result.

Z Axis Homing - YouTube

Looks good.

I originally thought you'd maybe gone a bit over the top with deciding to do the mods to the machine... then I read your thread over at mycncuk and well, d*mn... that's bad.

I can understand mistakes being made, but the state of that machine was shocking (no pun intended regarding the electrics).

It never ceases to amaze me that people don't realise that shipping something out in that condition is going to cost them more in time and money in supporting the customer than what they saved by cutting corners in the first place.

Hows the CNC coming along?

I'm reluctant to even post as its gone far beyond any sort of trouble I could have dreamed up.

Complications with the Z axis mean a complete redesign of this assembly was necessary. I've done the CAD work and passed it onto a machinist friend of mine who'll cut the parts. Its being done as a favour(ie. cheap!) so its when he has a day to spare. For now I'm back using good old reliable methods!

To say I'm disappointed with the manufacturer of the CNC would be an understatement.

Attachments

Complications with the Z axis mean a complete redesign of this assembly was necessary.

That sucks. Sorry to hear.

Love the renderings, but, are you sure the vertical arms of the gantry are wide enough to prevent flex (specifically the blocks that run along the longest axis on the machine being far enough apart to make the gantry stable)?

Looking at my much smaller machine, the width of the gantry legs (below where the black box is in your first render) is 8" (~20cm).

are you sure the vertical arms of the gantry are wide enough to prevent flex (specifically the blocks that run along the longest axis on the machine being far enough apart to make the gantry stable)?

Not really ideal imo.

The spacing on these are 200mm too but without redesigning the entire machine(thought about it!) and spending months and ££££ its something I'll have to learn to live with. In practical terms its going to limit feed rate and DOC but considering the soft materials, wood and plastics, that it'll spend most of its time cutting there are other limits such as the stepper motors lack of torque at higher speeds that'll make it difficult to ever really see the limit. In a sense its a somewhat balanced design there.

Ah OK, if the width of the uprights are 200mm all the way up then they're sturdier than my machine (200mm reducing down to a smaller width), and I've not noticed problems running a 1/4" bit with a 1/4" depth of cut at 120" per minute (~3000mm/min) through MDF.

You may well be OK with that then - especially as you've got the spindle, which will have way more torque at lower rpm than my router.

You may well be OK with that then - especially as you've got the spindle, which will have way more torque at lower rpm than my router.

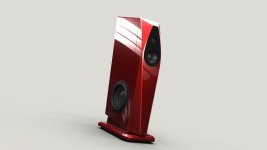

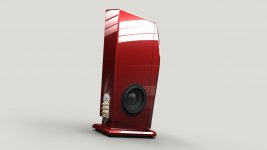

A few renders of the latest incarnation of the Aurora.

I do like this one although I liked the others as well so that's just a nod towards my indecision! I blame the CNC machine because if it were functional I'd be cutting instead of playing in CAD.

I do like this one although I liked the others as well so that's just a nod towards my indecision! I blame the CNC machine because if it were functional I'd be cutting instead of playing in CAD.

Attachments

Very nice indeed. Similar to the configuration that she-who-must-be-obeyed has allowed me to use to get the sub drivers I have into the living room. Not that I'm ever likely to get the time to build the things though... 😱

Is that (internally) a split mid/treble and bass cabinet, or is it a single volume inside?

Is that (internally) a split mid/treble and bass cabinet, or is it a single volume inside?

Ah your doing it all wrong Gordon. It should be you stating the rules... who am I kidding, no use fighting thousands of years of natural evolution!

As you suspected the mid is divided.

As you suspected the mid is divided.

Hi Shin,

Very impressive design and rendering. 😀

I'm a bit curious how the tweeter measurements would look like with that small horn configuration and how the diffraction effect of it looks like.

Nice job!

Regards

/Göran

Very impressive design and rendering. 😀

I'm a bit curious how the tweeter measurements would look like with that small horn configuration and how the diffraction effect of it looks like.

Nice job!

Regards

/Göran

Thanks Goran.

The small radius 'horn' on the tweeter in the renders can be considered cosmetic. The final version will have a wave guide but unfortunately until the CNC machine is working and I cut some test parts for measuring then its undecided. An asymmetrical horn similar to the loading Genelec uses in various monitors is a possibility too.

There's lots of variables to consider but my primary focus is the Apollo for now.

The small radius 'horn' on the tweeter in the renders can be considered cosmetic. The final version will have a wave guide but unfortunately until the CNC machine is working and I cut some test parts for measuring then its undecided. An asymmetrical horn similar to the loading Genelec uses in various monitors is a possibility too.

There's lots of variables to consider but my primary focus is the Apollo for now.

Attachments

Thanks Goran.

The small radius 'horn' on the tweeter in the renders can be considered cosmetic. The final version will have a wave guide but unfortunately until the CNC machine is working and I cut some test parts for measuring then its undecided. An asymmetrical horn similar to the loading Genelec uses in various monitors is a possibility too.

There's lots of variables to consider but my primary focus is the Apollo for now.

I would love to have one of your enclosure creations and design the passive cross-over in it. 🙂

I even think my wife wouldn't have any objections since the WAF factor is sky-high in your enclosure designs. 😛

Regards

/Göran

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Apollo Construction Diary