hi stan

i saw your pm .

best plan is to make a test box,these path lenghts are diffecult to guestimate.

are measurements in cm ok?

i wil atempt the next week.

i saw your pm .

best plan is to make a test box,these path lenghts are diffecult to guestimate.

are measurements in cm ok?

i wil atempt the next week.

hi stan

i saw your pm .

best plan is to make a test box,these path lenghts are diffecult to guestimate.

are measurements in cm ok?

i wil atempt the next week.

Thank Eric

Inches is better for me.

FINALLY!

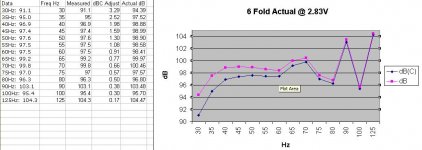

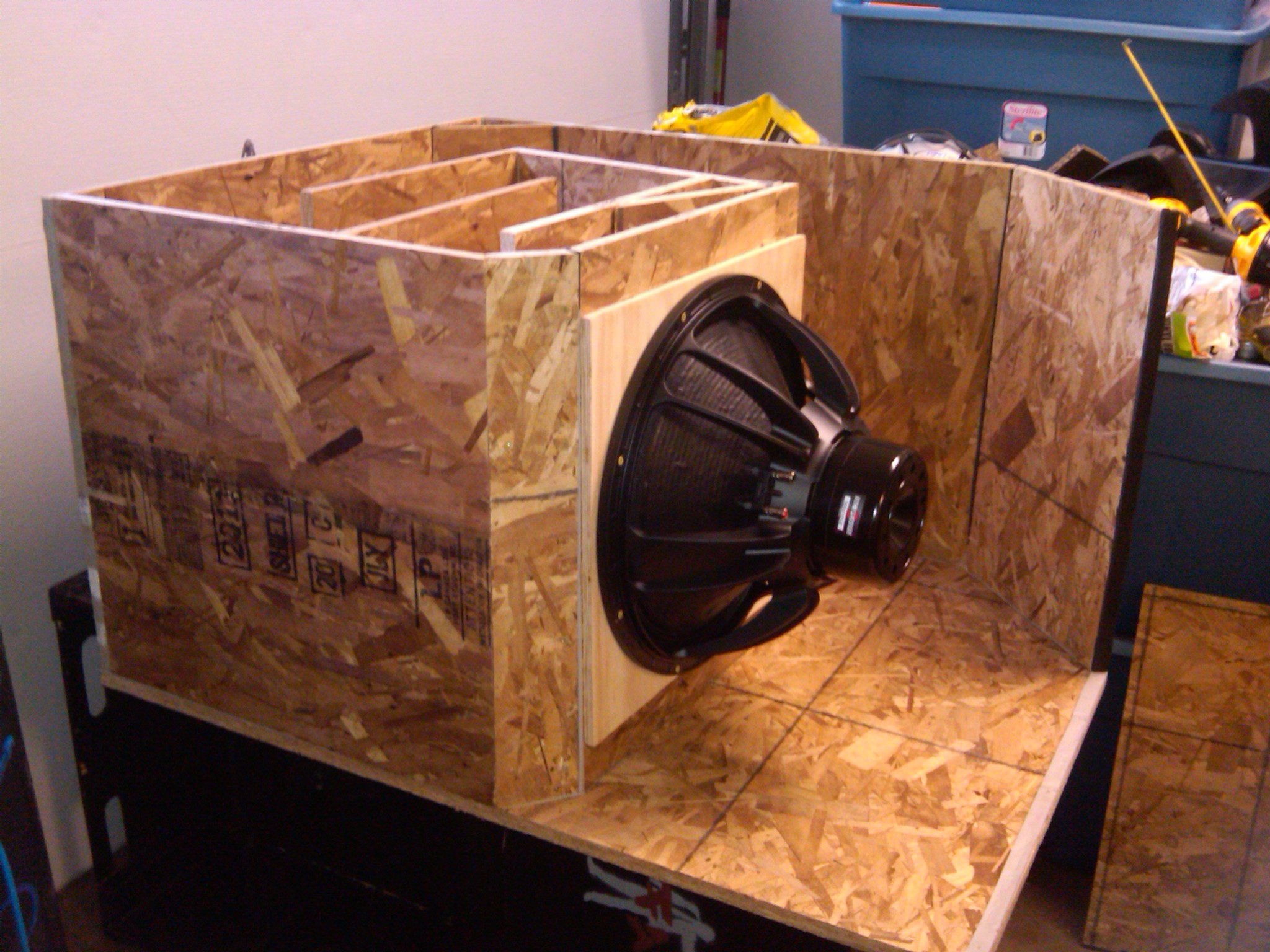

Did some tests of the 'Real 6 Fold' test box today:

Enclosure: "18in 30Hz - Real 6 Fold TH" aka "6 Fold" aka "Real 6 Fold" aka "R6F"

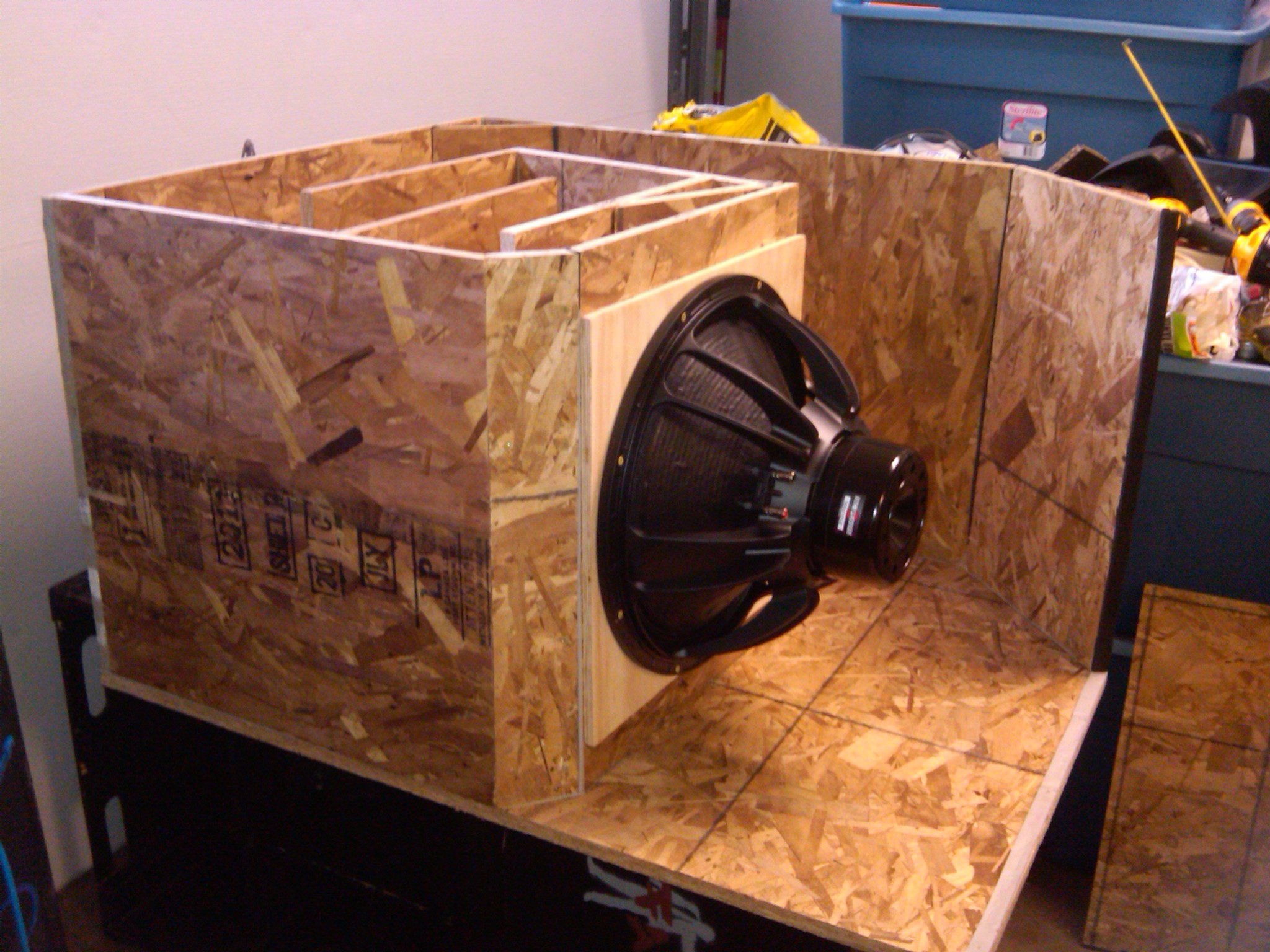

Test Box version: 3/4" OSB (subfloor) ply. Unbraced. Spacer for driver is 1/2" aurauco (had some extra laying around). Curved driver baffle entrance that is now being implemented in the Xoc1 TH-18 was used in this enclosure.

Designer: Xoc1

Driver: B&C 18SW100

Amp: QSC PLX3402

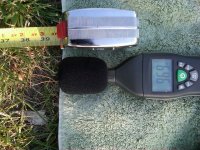

Volt-Ohm Meter: Blue-Point MT574

SPL Meter: American Recorder Technologies SPL-8810

*Settings:

-Weighting: C

-Time weighting: Fast

-Sound level: Hi = 60-130dB

Conditions: ground plane, outdoors, over grass

The following measurements were done at 1W/1M (3.3 feet or 3'4"). The driver tested is published as 8 ohms from the manufacturer. Amplifier voltage of 2.83v was measured at the driver's terminals.

*Please remember, C-weighting has NOT been accounted for/factored in and the appropriate amount of dB need to be added to these measurements to compensate. I only have an image of the graph/curve without exact numbers to calculate with.

30Hz: 91.1

35Hz: 95.0

40Hz: 96.9

45Hz: 97.4

50Hz: 97.6

55Hz: 97.5

60Hz: 97.5

65Hz: 99.2

70Hz: 99.8

75Hz: 97.0

80Hz: 96.3

90Hz: 103.1

100Hz: 95.4

125Hz: 104.3

I do not have 85Hz, 95Hz or 105-120Hz tones as you may have already guessed.

I played a single track for program material and turned it up. The meter read 122dB just as the amp limit light illuminated. Not bad for a flexing box that jumps forward 1/2" at a time as the kick drum pushes on. I highly dislike this OSB stuff - splits, cracks, strips (even with deck screws (better luck w/impact driver)). Both vinyl and rubber gasket tape/weatherstripping was used in place of glue for this test box.

The driver is not broken in yet, but it gives a nice, full-bodied sound and feel. I am playing with the idea of building the TH-18 for more SPL at events/shows (or the extended version to save 100L internal over this 6 Fold while maintaining the 30-35Hz response).

There are many other 18" drivers that work very well in this enclosure:

18SW115

18TBW100

18NW100

18TBX100

18NLW9600

18NLW9000

18LW2400

to name a few.

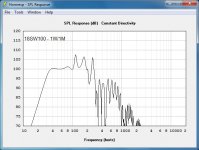

Below I've attached a photo of the drive voltage used, SPL reading at 40Hz, measurement conditions (SS15s shown), the HR 1w response plot and a few photos for size comparison.

Cheers!

Did some tests of the 'Real 6 Fold' test box today:

Enclosure: "18in 30Hz - Real 6 Fold TH" aka "6 Fold" aka "Real 6 Fold" aka "R6F"

Test Box version: 3/4" OSB (subfloor) ply. Unbraced. Spacer for driver is 1/2" aurauco (had some extra laying around). Curved driver baffle entrance that is now being implemented in the Xoc1 TH-18 was used in this enclosure.

Designer: Xoc1

Driver: B&C 18SW100

Amp: QSC PLX3402

Volt-Ohm Meter: Blue-Point MT574

SPL Meter: American Recorder Technologies SPL-8810

*Settings:

-Weighting: C

-Time weighting: Fast

-Sound level: Hi = 60-130dB

Conditions: ground plane, outdoors, over grass

The following measurements were done at 1W/1M (3.3 feet or 3'4"). The driver tested is published as 8 ohms from the manufacturer. Amplifier voltage of 2.83v was measured at the driver's terminals.

*Please remember, C-weighting has NOT been accounted for/factored in and the appropriate amount of dB need to be added to these measurements to compensate. I only have an image of the graph/curve without exact numbers to calculate with.

30Hz: 91.1

35Hz: 95.0

40Hz: 96.9

45Hz: 97.4

50Hz: 97.6

55Hz: 97.5

60Hz: 97.5

65Hz: 99.2

70Hz: 99.8

75Hz: 97.0

80Hz: 96.3

90Hz: 103.1

100Hz: 95.4

125Hz: 104.3

I do not have 85Hz, 95Hz or 105-120Hz tones as you may have already guessed.

I played a single track for program material and turned it up. The meter read 122dB just as the amp limit light illuminated. Not bad for a flexing box that jumps forward 1/2" at a time as the kick drum pushes on. I highly dislike this OSB stuff - splits, cracks, strips (even with deck screws (better luck w/impact driver)). Both vinyl and rubber gasket tape/weatherstripping was used in place of glue for this test box.

The driver is not broken in yet, but it gives a nice, full-bodied sound and feel. I am playing with the idea of building the TH-18 for more SPL at events/shows (or the extended version to save 100L internal over this 6 Fold while maintaining the 30-35Hz response).

There are many other 18" drivers that work very well in this enclosure:

18SW115

18TBW100

18NW100

18TBX100

18NLW9600

18NLW9000

18LW2400

to name a few.

Below I've attached a photo of the drive voltage used, SPL reading at 40Hz, measurement conditions (SS15s shown), the HR 1w response plot and a few photos for size comparison.

Cheers!

Attachments

-

18in 30hz - Real 6 Fold inside.jpg564.8 KB · Views: 922

18in 30hz - Real 6 Fold inside.jpg564.8 KB · Views: 922 -

18in 30hz - Real 6 Fold voltage.jpg704.2 KB · Views: 711

18in 30hz - Real 6 Fold voltage.jpg704.2 KB · Views: 711 -

18in 30hz - Real 6 Fold spl at 40Hz.jpg938.7 KB · Views: 671

18in 30hz - Real 6 Fold spl at 40Hz.jpg938.7 KB · Views: 671 -

18in 30hz - Real 6 Fold vs SS15.jpg533 KB · Views: 667

18in 30hz - Real 6 Fold vs SS15.jpg533 KB · Views: 667 -

18in 30hz - Real 6 Fold indoor.jpg777.4 KB · Views: 660

18in 30hz - Real 6 Fold indoor.jpg777.4 KB · Views: 660 -

SS15 measurement conditions 1.jpg555.5 KB · Views: 325

SS15 measurement conditions 1.jpg555.5 KB · Views: 325 -

SS15 measurements conditions 2.jpg688.4 KB · Views: 283

SS15 measurements conditions 2.jpg688.4 KB · Views: 283 -

R6F 18SW100 1w response.jpg79.2 KB · Views: 368

R6F 18SW100 1w response.jpg79.2 KB · Views: 368

I should look into REW. I have Smaart, but: haven't learned proper calibration procedure yet, didn't have time to learn today and a friend generously loaned me the SPL meter.

I've built some test boxes from OSB - boxes that were so good(flex and vibration free) folks want to buy them, even unfinished. You have to do it right, glue and fine gauge brads or possibly staples. Why screw up your test box by not actually gluing the thing together solid is a waste of time - forget the frufru foam gasket sillyness and put it together like you mean it. 😉

Sexy OSB box bronze medal for U though man

Sexy OSB box bronze medal for U though man

If it weren't a test box, I would've PL Premium'd it like my other solid boxes. This was meant to be put together in a way I could change panels if needed - as this is a prototype build. There are parts of this enclosure that haven't been proven. We all agreed I should build it with removable parts in the case I should need to make an adjustment prior the final draft.

However, as time went on in the build, I did wish I had glued it. Just because of the fact that I could have sold it to someone if I didn't particularly like it. But that led my thinking on to wishing I used higher grade ply, in case I sold it. Then bracing...then handles.... So, maybe it's good I didn't get carried away and kept it as we originally planned.

At least now I'll have templates for the good baltic birch

However, as time went on in the build, I did wish I had glued it. Just because of the fact that I could have sold it to someone if I didn't particularly like it. But that led my thinking on to wishing I used higher grade ply, in case I sold it. Then bracing...then handles.... So, maybe it's good I didn't get carried away and kept it as we originally planned.

At least now I'll have templates for the good baltic birch

Hi Crescendo

Did a quick spreadsheet for the dB(C) compensation.

Apologies for my naff spreadsheet skills!

That cab has some serious low end grunt🙂

Hopefully the cone is well under control.

122 db at clipping, is that with 700W or 2200w!

How low can you go and keep the cone from over excursion?

Regards

Xoc1

Did a quick spreadsheet for the dB(C) compensation.

Apologies for my naff spreadsheet skills!

That cab has some serious low end grunt🙂

Hopefully the cone is well under control.

122 db at clipping, is that with 700W or 2200w!

How low can you go and keep the cone from over excursion?

Regards

Xoc1

Attachments

Looks great, Martin! Thank you.

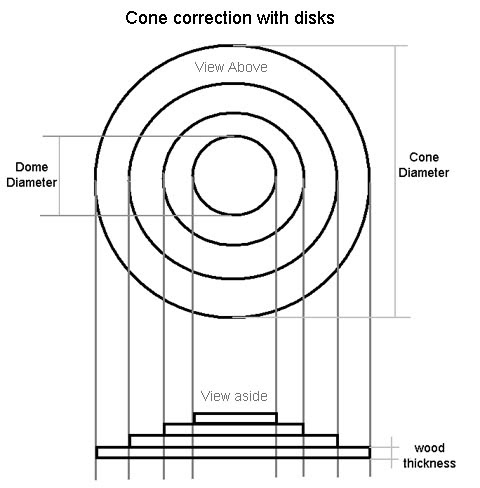

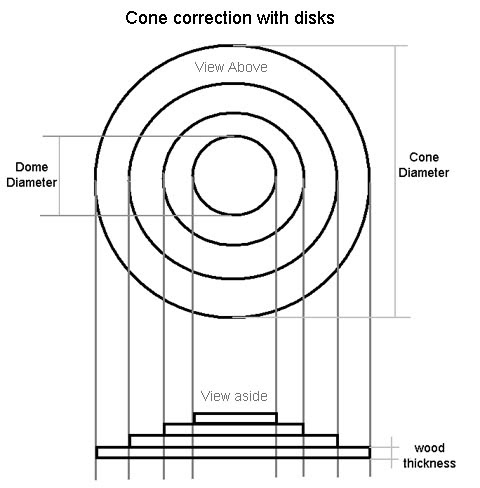

I'd like to implement cone make-up as Djim suggested to help get the response closer to the HornResp model.

The cone appears to be controlled quite well. This S-shaped baffle cut-out might have helped control/compression - but, it may be the culprit of slightly low SPL.

It was 122dB at clipping on the bridged setting (2200W). My apologies for not knowing what frequency(ies) at which it clipped (i.e. if it clipped at 40Hz, SPL may have actually been 124dB, etc. due to the C-weighting)

How low? Let me check...brb...

It just took 25Hz at 700W just at clip light (clip limiter on) with no HPF, no excursion noise. I got some excursion noise at 20Hz and 16Hz at the 3rd signal light (4th light is clip/limit light). Sorry, don't have volt meter set up. Maybe tomorrow?

I'd like to implement cone make-up as Djim suggested to help get the response closer to the HornResp model.

The cone appears to be controlled quite well. This S-shaped baffle cut-out might have helped control/compression - but, it may be the culprit of slightly low SPL.

It was 122dB at clipping on the bridged setting (2200W). My apologies for not knowing what frequency(ies) at which it clipped (i.e. if it clipped at 40Hz, SPL may have actually been 124dB, etc. due to the C-weighting)

How low? Let me check...brb...

It just took 25Hz at 700W just at clip light (clip limiter on) with no HPF, no excursion noise. I got some excursion noise at 20Hz and 16Hz at the 3rd signal light (4th light is clip/limit light). Sorry, don't have volt meter set up. Maybe tomorrow?

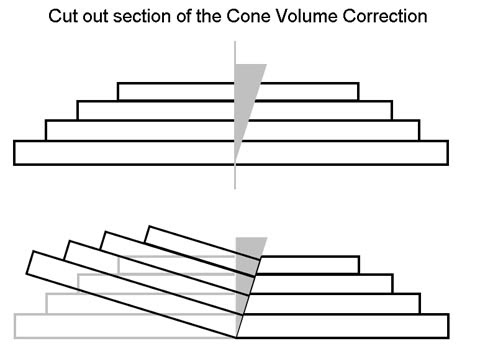

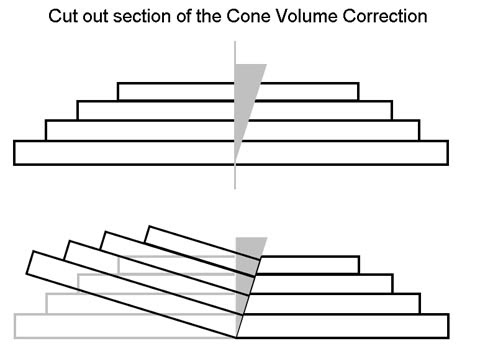

An example of a simple cone correction made out disks cut from sheets:

To make it fit for the 6-Fold you need to cut out a piece:

You can cut out rings instead of full disks to save weight...

To make it fit for the 6-Fold you need to cut out a piece:

You can cut out rings instead of full disks to save weight...

Hi Justin,

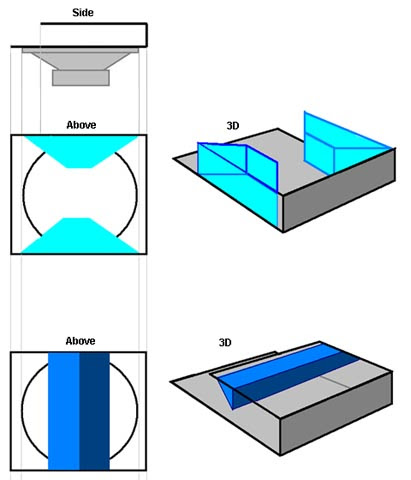

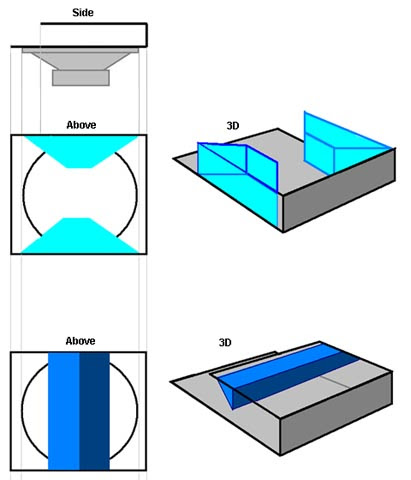

The shape of the cone volume correction can also be simplified since the system doesn't see/recognise shapes but only reacts to volume at a specific position.The only rule is that the total volume these corrections occupy are the same as the volume of the cone.

Two other examples of cone correction:

The shape of the cone volume correction can also be simplified since the system doesn't see/recognise shapes but only reacts to volume at a specific position.The only rule is that the total volume these corrections occupy are the same as the volume of the cone.

Two other examples of cone correction:

I think that DJMs bottom suggestion looks promising.

Crescendo your development cab might not be the ultimate when it comes to performance but having the ability to take panels out and change things gives us the chance to learn something that we are not going to get from a computer. 😀

I think the 3D wedge for the cone correction, a full size cut out for the baffle, and removing the extra tapered panel from s1 to s2 would be the way to go.😉

Unfortunately my home CAD computer is toast at the moment. I am waiting on a new PSU to be delivered.😱

Regards Xoc1

Crescendo your development cab might not be the ultimate when it comes to performance but having the ability to take panels out and change things gives us the chance to learn something that we are not going to get from a computer. 😀

I think the 3D wedge for the cone correction, a full size cut out for the baffle, and removing the extra tapered panel from s1 to s2 would be the way to go.😉

Unfortunately my home CAD computer is toast at the moment. I am waiting on a new PSU to be delivered.😱

Regards Xoc1

For testing purposes the disk method is the easiest because its shape fits trough the baffle speaker cut out and you can screw them temporally against the upper panel.

For final production it is better to use one of the last two options as presented in post#713 because they improve the strength of the construction and use less wood.

For the 6-Fold I would not cut out the speaker completely but combine it with the S2 repositioning option. Make sure the panel cut out does not go any further than the cone volume correction begins otherwise you are changing the impedance of the system.

(Side note: High compression ratio throats do not work correctly with Cone Volume corrections)

First picture: Baffle cut out (with S2 repositioning option)

Second picture: Baffle cut out plus Cone Volume Correction

For final production it is better to use one of the last two options as presented in post#713 because they improve the strength of the construction and use less wood.

For the 6-Fold I would not cut out the speaker completely but combine it with the S2 repositioning option. Make sure the panel cut out does not go any further than the cone volume correction begins otherwise you are changing the impedance of the system.

(Side note: High compression ratio throats do not work correctly with Cone Volume corrections)

First picture: Baffle cut out (with S2 repositioning option)

Second picture: Baffle cut out plus Cone Volume Correction

Last edited:

For testing purposes the disk method is the easiest because its shape fits trough the baffle speaker cut out and you can screw them temporally against the upper panel.

For final production it is better to use one of the last two options as presented in post#713 because they improve the strength of the construction and use less wood.

The 2nd option in #713 shouldn't be too difficult for testing purposes. I can remove one whole side and slide it in. Would probably take much less time to make, too.

For the 6-Fold I would not cut out the speaker completely but combine it with the S2 repositioning option. Make sure the panel cut out does not go any further than the cone volume correction begins otherwise you are changing the impedance of the system.

(Side note: High compression ratio throats do not work correctly with Cone Volume corrections)

First picture: Baffle cut out (with S2 repositioning option)

Second picture: Baffle cut out plus Cone Volume Correction

With this setup, should I remove the angled piece at S1 also, like Martin suggested?

Which component is creating the high compression? The S-shape opening?

Well, to be honest I lost track a little on the 6-Fold. Maybe you could (re)post the exact drawings and corresponding HornResp inputs of your actual build cab (or even better start a new thread for it) to clear things up 🙂

As far as S-Shape opening as it is, it would probably run under the Cone Volume Correction. That could change the impedance too much of the system so you have to cut it back a little (till a quarter of the diameter) , just like the last picture of post#716.

As far as S-Shape opening as it is, it would probably run under the Cone Volume Correction. That could change the impedance too much of the system so you have to cut it back a little (till a quarter of the diameter) , just like the last picture of post#716.

Last edited:

On another note....

WHOLE EEE SHHHHYT this cab provides a ton of low end.

We 'tested' it for a few minutes with a bit of low material at our regular venue. I was pleasantly surprised ......that I wasn't let down. This cab on one channel of my PLX3402 (1000W less than would be used had it been it's debut) filled the entire bottom floor of the bar/club just as much as our 2 BFM T48, 2 SS15 and the 2 house QSC active 18" - with even more bottom. "As (you guys) were talking, your voices fluttered" my colleague said after our quick check.

We didn't feel a ton of that chest compressing feel with the little material we tried. Not sure if it's due to the lack of cone make up in this cab or if it's purely lack of SPL at those frequencies that the cone make up won't recover. This left us with the urge to give the TH-18 a try. Can't say for sure that it's optimized to the fullest for the 18SW100. Our hopes is that we won't miss the couple Hz at the very bottom. I tried to mimmic the lack of super low response by cutting out some 30Hz by a few dB while testing the 6 Fold and the difference wasn't enough to really justify not trying the TH-18. A wicked system would be a 3-way setup with the 6 Fold and some SS15s for that chest smack. *Thinking* Are my hopes to high, thinking I might possibly achieve both with the TH-18?

Note: While we definitely have tracks that contain 30Hz content, they are usually mellower tracks that probably won't get played out too much. AND when DJing, tracks frequently get pitched/sped up which will raise the low content's frequency also.

I would still like to try this cone make up in the 6 Fold and test it to provide some more info so we can keep learning. Should this also be implemented in the TH-18? Feel free to post that answer in the other thread 🙂

Thanks guys! I'm super addicted and all of these findings and last night's sample has got me in a great mood today 🙂 🙂 🙂

WHOLE EEE SHHHHYT this cab provides a ton of low end.

We 'tested' it for a few minutes with a bit of low material at our regular venue. I was pleasantly surprised ......that I wasn't let down. This cab on one channel of my PLX3402 (1000W less than would be used had it been it's debut) filled the entire bottom floor of the bar/club just as much as our 2 BFM T48, 2 SS15 and the 2 house QSC active 18" - with even more bottom. "As (you guys) were talking, your voices fluttered" my colleague said after our quick check.

We didn't feel a ton of that chest compressing feel with the little material we tried. Not sure if it's due to the lack of cone make up in this cab or if it's purely lack of SPL at those frequencies that the cone make up won't recover. This left us with the urge to give the TH-18 a try. Can't say for sure that it's optimized to the fullest for the 18SW100. Our hopes is that we won't miss the couple Hz at the very bottom. I tried to mimmic the lack of super low response by cutting out some 30Hz by a few dB while testing the 6 Fold and the difference wasn't enough to really justify not trying the TH-18. A wicked system would be a 3-way setup with the 6 Fold and some SS15s for that chest smack. *Thinking* Are my hopes to high, thinking I might possibly achieve both with the TH-18?

Note: While we definitely have tracks that contain 30Hz content, they are usually mellower tracks that probably won't get played out too much. AND when DJing, tracks frequently get pitched/sped up which will raise the low content's frequency also.

I would still like to try this cone make up in the 6 Fold and test it to provide some more info so we can keep learning. Should this also be implemented in the TH-18? Feel free to post that answer in the other thread 🙂

Thanks guys! I'm super addicted and all of these findings and last night's sample has got me in a great mood today 🙂 🙂 🙂

Last edited:

- Home

- Loudspeakers

- Subwoofers

- C/E/X PA Flat to 30 (FT30) PA TH Awesomeness