Okay gettin there! Cut out the brace using the spare wood, yes it was a pain in the ***! Please excuse the cuts I know they look like a 3 year old cut them out, my jig saw sucks, as do my jig saw skills lol

^as you can see i have the speaker on a movers dolly because it's killing my back trying to lift this thing up and move it around in my tiny workspace!

^as you can see i have the speaker on a movers dolly because it's killing my back trying to lift this thing up and move it around in my tiny workspace!

Last edited:

Fast man! But it is looking good.

Are you going to use 'bars' or 'broomsticks' like suggested in post #135?

Are you going to use 'bars' or 'broomsticks' like suggested in post #135?

Yeah i can put those in after the side is glued on. I don't think i need a ton of bracing, correct? one should suffice just to stop the flexing...?

Correct me if I'm wrong, but danley's sub doesn't have a large brace down the center like this one, does it? Any insight as to why he doesn't use one? I don't think he is using a superior material....

Correct me if I'm wrong, but danley's sub doesn't have a large brace down the center like this one, does it? Any insight as to why he doesn't use one? I don't think he is using a superior material....

Some use aluminium pipes with 'draadeind' (sorry that's dutch but I haven't a clue for the English word) in them.

That way the diameter is the smallest and you have a easy way to fix the bracing with it. The pipes will keep the inner distance perfect and choose shallow end nuts (you can make them drop in the wood, sorry for the English again) and something like 2 component machine glue for both nuts to fix them from the outside.

In other words: nut, side wall left, pipe, middle bracing, pipe, side wall right, nut and then the 'draadeind' trough all of them...... pffffffffff....and some rings....

With wooden 'broomsticks' use at least 3,5cm (35mm) but make sure you glue them and fix them with extra long screw bolts (pre-drill the wood to prevent splitting) from the outside. If you don't want them to go trough the bracing in the middle, you can use a two tapped end screw type (connecting screws? two side screws? )

)

An externally hosted image should be here but it was not working when we last tested it.

That way the diameter is the smallest and you have a easy way to fix the bracing with it. The pipes will keep the inner distance perfect and choose shallow end nuts (you can make them drop in the wood, sorry for the English again) and something like 2 component machine glue for both nuts to fix them from the outside.

In other words: nut, side wall left, pipe, middle bracing, pipe, side wall right, nut and then the 'draadeind' trough all of them...... pffffffffff....and some rings....

With wooden 'broomsticks' use at least 3,5cm (35mm) but make sure you glue them and fix them with extra long screw bolts (pre-drill the wood to prevent splitting) from the outside. If you don't want them to go trough the bracing in the middle, you can use a two tapped end screw type (connecting screws? two side screws?

)

)

Last edited:

threadbar(weet alleen niet met een r of 2 rr)😀Some use aluminium pipes with 'draadeind' (sorry that's dutch but I haven't a clue for the English word) in them.

An externally hosted image should be here but it was not working when we last tested it.

Thanks (en eentje is genoeg 😉)threadbar (weet alleen niet met een r of 2 rr)😀

Bracing the mouth

Hi Y'all,

Nice job! 🙂

I would suggest using three sideways braces, two up front, and one behind the driver.

Maybe schedule 120 1/2" PVC pipe (O.D. .840 / I.D. .480 / Wall .170 nom.) w/ a 3/8-16 allthread? Or just 3/4" - 1" wood dowels with #12 wood screws?

Regards,

Hi Y'all,

Nice job! 🙂

I would suggest using three sideways braces, two up front, and one behind the driver.

Maybe schedule 120 1/2" PVC pipe (O.D. .840 / I.D. .480 / Wall .170 nom.) w/ a 3/8-16 allthread? Or just 3/4" - 1" wood dowels with #12 wood screws?

Regards,

Hi Oliver, at the front you gain much more from an enforced grill with framing as suggested in post # 17 of this thread. That way it will also prevent the bottom panel from flexing. Just three bars without the enforced grill is less efficient.

Hi Djim,

I agree, I was thinking in front of the driver, and behind the driver in addition to the metal grill. Maybe the FEA print-outs can be a guide?

Regards,

I agree, I was thinking in front of the driver, and behind the driver in addition to the metal grill. Maybe the FEA print-outs can be a guide?

Regards,

Yes, FEA print outs can be a very good guide as long all parameters are correct. But always remember most (simple) FEA visualisations don't have the ability to imply damping of materials on soundwaves (high speed cams never lie😉)

Hi All

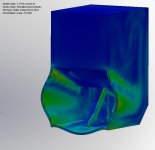

3 screen prints showing the TH 18 being blown apart with internal pressure on the panels

First without no ties

Second with 2 ties as Djims suggestion

Third with 2 ties and some double material added to the speaker base.

The pressure is consistent for all 3 sims the telling parameter is the scaling factor used. The last sim shows deformation of less than one third of the first.

3 screen prints showing the TH 18 being blown apart with internal pressure on the panels

First without no ties

Second with 2 ties as Djims suggestion

Third with 2 ties and some double material added to the speaker base.

The pressure is consistent for all 3 sims the telling parameter is the scaling factor used. The last sim shows deformation of less than one third of the first.

Attachments

Small detail difference. In case you are going to use an enforced grill place the first 'tie' ('bar') almost 1/2 way between the grill and the bar that is crossing the middle brace.

Pink = attachments for grill points

Red = attachments for 'ties' ('bars')

Pink = attachments for grill points

Red = attachments for 'ties' ('bars')

Last edited:

Even with the doubling of the base there is still more deviation in the base than the sides with the tiebars

Regards

Martin

Regards

Martin

Last edited:

That's why I prefer to use the tie bars with the combination of an enforced grill. It's the combination of horizontal and vertical reinforcements.Even with the doubling of the base there is still more deviation in the base than the sides with the tiebars

- Home

- Loudspeakers

- Subwoofers

- TH-18 Flat to 35hz! (Xoc1's design)