I just thought I’d drop a note (a long note) here about my recent experiences which I hope will help anyone who considers using solid wood as speaker cabinet building material. If you don’t want to read my story, you can go to the end and see my conclusions.

I’d like to start out by saying that I love working with solid wood; building entertainment units, shelves, and most of all speakers. I especially like working with thick slabs of heavy wood. It’s hard to explain but it feels like you’re carving and moulding your speaker cabinets instead of assembling panels. Which of course is nonsense, but I’m a tactile aesthetic kind of person; the kind of intolerable amateur woodworker who is always running a hand along a sanded surface and smiling. It makes me happy.

To be clear, I’ve got no beef with MDF or plywood – I have built two sets of speakers using MDF and one with ply – I just loved working on all the speakers I built with solid wood. I know the risks of building with a totally organic material like solid wood and I understand the extra care required in the treatment of the material, but I also appreciate that with care you can achieve furniture grade results. And my wife appreciates it too. Which is one of the reasons I can get away with filling our house with big speakers.

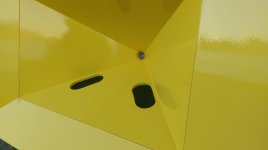

The speakers which this story is about are 1.45m tall floor-standers made of 31mm panels of solid Pacific Maple which give a lovely gold/tan/red colour in the grain. The back panel and bottom panel were made of a sandwich of ply and MDF because I had to cut costs somewhere. Wood is expensive.

The basic details of the speakers are below for those who are interested:

• Tweeter: Scan-speak D2905/9900

• Mid = Eton 7-360/37

• Woofers = 2 x Scan-speak 25W/8565-01

• Net internal volume of 133 litres with rear firing port tuned to 22Hz

I won’t go into the crossover details here because there were seven revisions since the original crossover design… I like to tinker.

It had third order filters with some impedance equalisation, mid smoothing and tweeter attenuation.

I was younger back then and I make no apologies for loving bass that went boom. Yes, I know it was wrong: I measured a 6dB peak around 50Hz – 60Hz, but I left it and I loved it! I listened to a lot more dance music back then.

Anyway, I finished building the speakers in 2008 when I was living in the Crows Nest area of Sydney. Crows Nest is surrounded by water inlets, dripping forests, is reasonably close to the beach, is at sea level, and not least of all quite close to that big harbour of Sydney. All those points add up to humidity levels between 50% and 95% every day – hot or cold. Which is fine because the wood I used was purchased from a supplier in the local area. The speakers lived quite happily in Crows Nest for seven years without any sign of wear or damage. It seemed like they would be upsetting neighbours for decades to come.

This time last year, some big changes happened in our lives and we had to move to Canberra. Canberra is an inland town, surrounded by cleared farmland, is at altitude, and has no natural waterways. There is no humidity to speak of whether it’s hot, cold or even raining. Canberra, although being a lovely town, is practically a desert.

After about three months of living in Canberra I noticed some cracks appearing in a few of the joints of the speakers. A month later the cracks had broadened and a few more had appeared in other joints. Almost all the panels had cracked in some way except for the ply/MDF back panel.

You can see in the picture the dark line where the front panel is pulling away from the sides. The top panel is also separating.

I found a local timber yard and furniture maker called Thor’s Hammer (great name!) which was recommended by friends who had bought furniture from them. I spoke to a bloke there named Gerry and told him about my situation. He said, “Yeah, that will happen. You should expect the moisture content to drop by about 12%, which means a lot of shrinkage.”

I asked if there was anything I could do to stop the moisture loss like sanding back and using oil to seal instead of varnish or something. The wood was expensive and I didn’t want to start again. Could I strengthen the joints?

“Nope. It’s going to shrink anyway. The joints are probably fine. The best you can do is leave it another couple of months to make sure the wood has reached the point where it’s as dry as it’s going to get, then sand back the varnish, fill the gaps with resin, sand back again, and use a flexible natural finish like oil.”

I had some time while I waited for the speaker cabinets to find their natural Canberra level of moisture and I figured if I was going to have to pull the speakers down, then I may as well tinker some more. I always thought the speakers sounded good (in all their versions), but the bass really was boomy with too much excursion. I’m older and …well … just older now and don’t appreciate the boom quite as much. I fired up Soundeasy and got designing. After a couple of months of designing and comparing options, I decided since the cabinets were already huge I could quite easily turn them into a transmission line.

I replaced the ply/MDF back panels with solid Pacific Maple like the rest of the cabinet. Sourced locally in Canberra. I took some more advice from Thor’s Hammer and left the lengths of wood inside to season for a month before joining lengths and cutting them into panels. This was also to find their moisture equilibrium.

Four months of repairing, woodworking, construction and a lot of sanding later, I have functioning speakers again. I used oil instead of varnish, which made the wood grain in the cabinets a little darker, but nicer looking. I finished a few months ago, but I let them settle in before I wrote this just to make sure there wasn’t going to be any more movement. So far, all good.

The only issue I have with the gaps now is my own mistakes I made with the resin. Otherwise it’s smooth to the touch (I ran my hand along many times), and they have a bit of a reclaimed timber look about it. From one metre away you can’t tell that there were ever any gaps.

As for the sound, this was my first attempt at a transmission line and it lead to a lot of tinkering… I was in heaven! I had my measurement mic out every weekend for months! I had some phase issues which resulted in a slightly unorthodox fourth order filter for the woofers and third order for the mid and tweeter which did the trick. I did a lot of experimenting and ended up with lots of heavy stuffing in the transmission line which seemed to have only a little effect on the bass extension, but did tighten it up nicely. I now understand what people mean when they say their transmission line has tight and clean bass. It really is something different to the ported and sealed enclosures I’ve built. It goes deeper without lots of cone excursion and kickdrums have a nice clean “thump” without the boom. That’s all the subjective remarks I’ll make.

I am very happy with the results. So, this is a precautionary tale but like all good stories, the main character learns a thing or two along the way and it has a happy ending.

In conclusion, if you choose to build with solid wood:

• Solid wood behaves like a live material – it expands and contracts with moisture levels.

• If you build with solid wood be aware that moving to a different climate may cause your panels to split or buckle.

• Source your wood locally and season it. If possible leave it inside your house for a month or two before you build.

• Don’t be scared off. There are ways to repair the damage from split wood, but not ways to stop it.

I’m sorry this ended up so long. I started typing and it just went on.

I hope this has been helpful to anyone who considers using solid wood. I intend to continue using solid wood.

AJ

![IMG_20210506_122512[1].jpg](/community/data/attachments/862/862149-c7c9e555515178033cb1bcc4098cbd72.jpg?hash=x8nlVVFReA)

![IMG_20210506_092618[1].jpg](/community/data/attachments/862/862170-f392a2080c7688201ea810160b639b4d.jpg?hash=85KiCAx2iC)