Hi there,

Here is another cheap & cheerful (and useful!) project: a dielectric absorption test-set.

What is DA (dielectric absorption)?

In a nutshell, DA is a parasitic effect affecting dielectric materials, and the capacitors they are made of.

Any real capacitor can be modelled as an infinite series of RC circuits.

In "good" capacitors, the first RC's total a large capacitance, and similar series resistances, resulting in an ideal cap in series with the ESR being the // sum of elementary R's.

Higher order effects are essentially minimal, and all of the losses are concentrated in the ESR, or the Q, the tan delta, the parallel damping resistance, .... etc: all these parameters are perfectly equivalent, and can be mathematically converted into any other one.

DA is somewhat different: although it counts as losses as it is a dissipative process, its real impact is absolutely minimal.

For example, mica is infamously known as one of the worst dielectric regarding DA, yet its losses remain very low.

This is the reason why this particular loss process has received a special treatment.

Although the energetic impact is minimal, the effect on the signals is far from negligible.

In dielectrics affected by DA, the elementary RC's of the series decrease more slowly, meaning a significant part of the total capacitance is hidden behind large R's, and large RC time-constants.

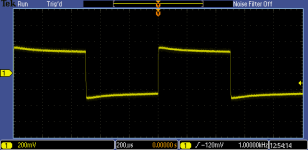

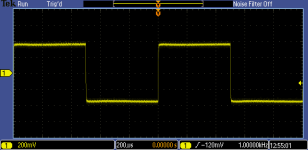

In practice, this means that when you attempt to charge or discharge such a cap very quickly, the farthest caps remain unaffected, and change the voltage and current after the event.

This delayed response leads to a host of unwanted effects, sometimes difficult to identify or attribute.

Some examples: the LF capacitance is larger than the HF one, sample-hold circuits show a small drop just after the sampling pulse, ramp generators have non-linearities, characterized by an excessive rise after the reset pulse, higher amplitude up to 50%, and lower amplitude afterwards.

It causes inaccuracies in the response of filters and equalization networks.

If you had the misguided idea of building a high-accuracy RIAA network from precision mica capacitors, the LF response would deviate from the ideal, even if you use 0.25% caps and 0.05% resistors.

In pulse circuits, it increases the settling time, in video signals, it causes streaking and lagging effects, and disrupts the black level, etc.

What causes DA?

The base dielectric material plays a major role, obviously, but many other factors also have an effect.

The presence of heterogeneities in the dielectric is an important one.

They can be discrete, like multi-sheet or multi-dielectrics caps, macroscopic as in layered materials like mica or granular materials like ceramics, or microscopic at the molecular level.

The presence of bubbles, voids, impurities, inclusions, wrinkles, fractures or other imperfections in the dielectric greatly increases the DA.

This means that composites, like PCB materials generally have a large DA.

The construction of the capacitor is extremely important: PP or PS are excellent dielectrics in theory, but a poor construction can totally ruin a capacitor based on these dielectrics.

Capacitors from the same production batch, in perfect condition, can display significant DA characteristics differences, even when all the rest is nominal.

DA is not systematically tested, but it is a good indicator of the quality and consistency of the production, as it is very sensitive to to the slightest contamination or deviation.

How is DA measured?

The universal method is to charge the CUT to a known voltage, keep it charged for a soaking time, discharge it briefly, let it recover completely disconnected, and finally measure the recovered voltage.

The ratio of the recovered voltage to the initial voltage is the DA value.

In this process, absolutely everything counts and influences the end result.

The only way to reproduce a result is to use strictly identical conditions.

Most accepted methods use time-scales of minutes or tens of minutes, and use mercury-wetted relays and similar devices.

Not very convenient for a fast, casual use.

The evaluator I propose does things more simply, but more importantly, it does so at a (comparatively) blindingly fast speed: the total cycle time is 1 second, and although the reading needs a little longer to settle, it is still tens of times faster than any "official" alternative.

What is the value of such an accelerated measurement?

Basically, it indicates DA when it is present and the parameters of the circuit have been tweaked to mimic "standard" results (remembering that there are in fact no such standards, it just follows the mainstream trend).

If you build the tester, you will have your own, stable reference, and if you test a number of known samples, you will get a feeling of what a good DA is.

If other DIYers build the same instrument, you will be able to compare your results with others.

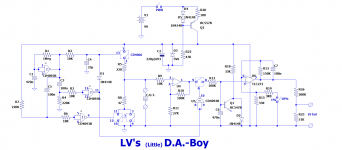

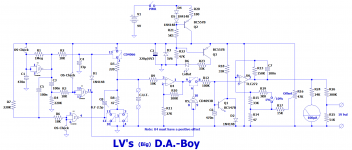

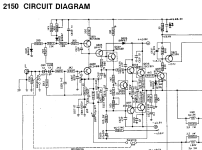

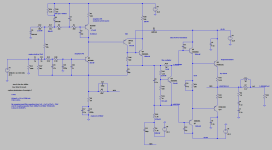

The circuit is simple and cheap, based mostly on commodities except for the opamp, which is not especially rare or expensive and can easily be substituted.

I propose two versions: one is adjustment-free and has no bells and whistles like a low-batt. indicator, the other has compensations and adjustments to improve the absolute accuracy.

The evaluator will work from 1nF to 10µF without needing to switch anything, and has two ranges: 1% full range, and 10% full range.

It is designed as a multimeter add-on, and plugs into the standard 3/4' spaced input ports of most digital multimeters: mains plugs and outlets use the same standard, meaning the tester is housed in the shell of an AC/DC wallwart.

The "luxury" version includes a small galvanometer, allowing a stand-alone operation.

The sensitivity is sufficient to distinguish between two slightly different flavors of PP caps.

The 10% range is sufficient for reasonably good caps: PP, PS, PET, PC, ceramic COG or X7R.

It is insufficient for high-k ceramics, Ecaps, bad paper caps, but you don't need a tester to be aware of that.

If you really need to know the details, you can add a range having a lower gain.

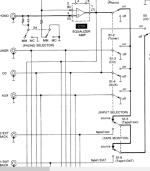

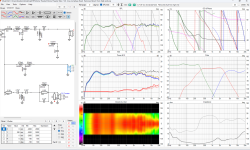

This is the "light" version:

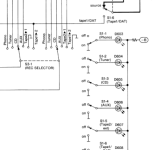

And this is the full one:

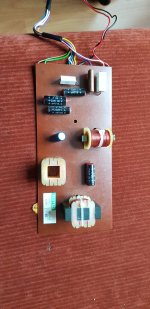

This is how my build looks:

A look inside: