I think I may have stumbled upon the first practical all passive crossover for the

Harsch XO topology, which provides a quasi-transient perfect response for a 2-way speaker. Normally the Harsch XO is only implemented in DSP because the delays required are too large to be practical.

I received my

Purifi PTT6.5 woofers a few days ago as part of the

GB organized by Norman Tracy. I have been thinking about what kind of speaker to make with this special driver. I was going to use either a ribbon tweeter, or fullrange and make it into a FAST with a low crossover around 1kHz. However, I have a speaker box that has been languishing for a few years since I could never finish it. I happened to have a 0.57 cu ft cabinet that I made for an RS180P and a WG300 waveguide fitted with an RS28F dome tweeter. The cabinet also was fitted with dual 6.5in passive radiators from Dayton. As a lazy person's first test, I pulled the RS180P and dropped the PTT6.5 in and it was nearly a perfect drop-in fit. The PTT6.5 OD on the bezel was just a couple of mm smaller than the RS180P. Continuing on the lazy trend, I connected the existing XO for the RS180P and an RS28F.

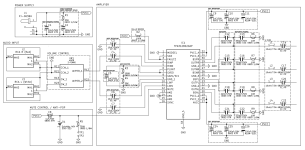

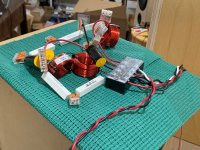

Surprisingly, it sounded very very good considering it's a totally different driver and 4ohms vs 8ohms. This got me motivated to really crank out a new speaker crossover to hear what this driver can do. So I setup my microphone (UMIK-1 calibrated by Cross Spectrum Labs), REW, and my new

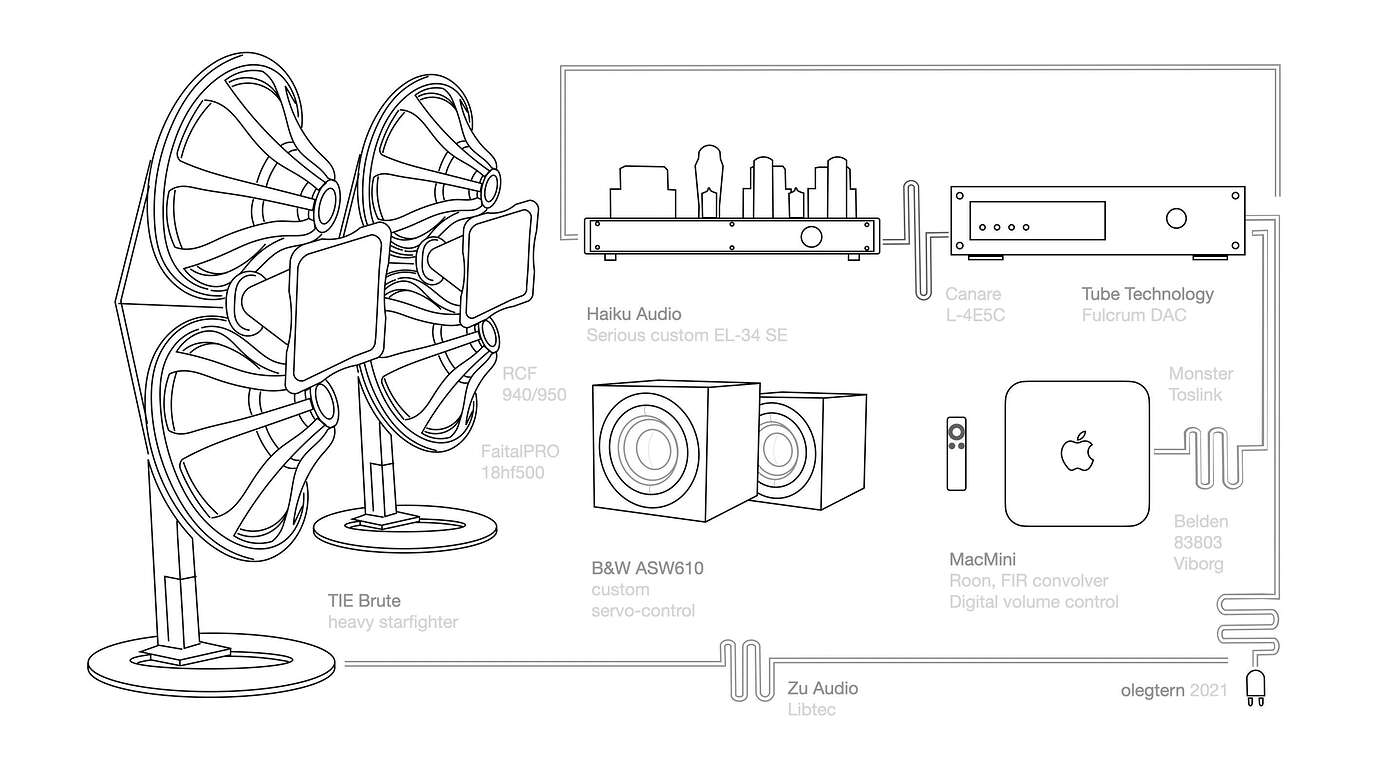

TPA3255 reference Class D amp with PFFB. Probably the only amp I have at present that can drive 4ohms (good for up to 300w+). Here is a photo of the test setup:

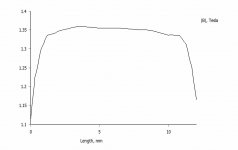

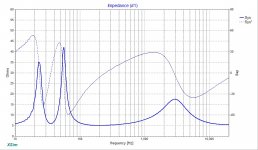

I began by measuring their T/S parameters with a DATS. Everything looked great and the values were within factory specs for Qts, fs, and SPL. Here is the DATS measurement:

The drivers were almost perfectly matched too - very unusual to have two drivers with an impedance curve that is near identical.

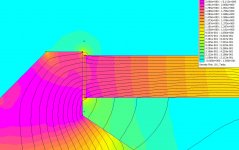

I took some frequency response FRD data with just the woofer, the tweeter, and both combined in order to figure out the acoustic center offset via acoustic interferometry to be done in Xsim. Here is a plot showing the predicted combined raw driver response with the simulated one for a 19mm offset of the tweeter relative to the woofer:

This was measured with the mic along the woofer axis (I plan to put the woofer on top and tweeter on the bottom to get a little extra time of flight delay for the tweeter while still keeping the front baffle flat), I get a 19mm offset of the tweeter and waveguide based on the interferogram match of the simulated and actual combined measurement. This is the same technique that I used on the

10F/RS225 FAST speaker in order to get time alignment. It works here even though the crossover curves are not anywhere near 1st order, but closer to what is seen on a Harsch XO with a steep 4th order low pass on the woofer and less steep 2rd order high pass on the tweeter. Furthermore, since the Purifi PTT6.5 driver has such a nice flat response out to nearly 4khz, I was able to run a high XO point of about 3.6kHz, which corresponds to a time of flight delay distance of 47.5mm (1.87in). By using the woofer as the main acoustic axis, we are able to approximately delay the tweeter by a little extra due to triangulation.

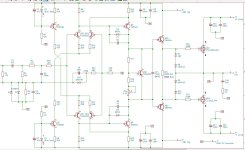

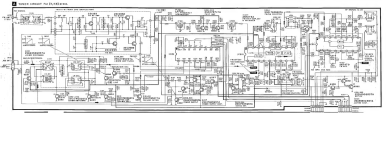

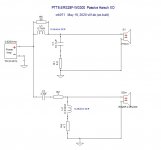

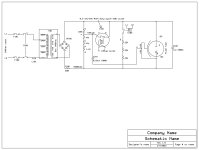

In Xsim, I modeled the following very simple crossover using only 2 inductors, 2 capacitors, and four resistors (the prototype uses multiple values from my XO development kit to build up the desired values), was able to achieve a very Harsch-like textbook XO profile. Here is the crossover schematic, as-built:

Here is a photo of the prototype crossover as implemented using my XO development kit:

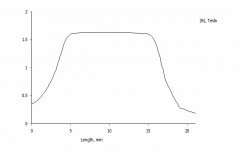

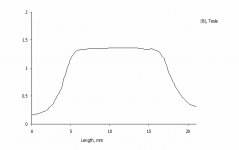

Here is the predicted frequency response plot for this crossover:

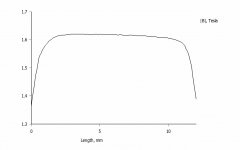

Here is the predicted impedance plot for this crossover:

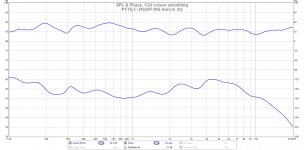

Here is the measured frequency response for 1/24th octave smoothing. Note the tell-tale dip in the system response relative to the woofer only response just to left of the crossover frequency. This is a classic sign that the Harsch XO was set up correctly.

The other tell-tale sign that it is a Harsch is that there is about a 55 deg phase shift bump from the nominal, and here we see a fairly flat phase response from 100Hz to 10KHz with an approximate 55 deg rise.

And finally, the clearest indication that this crossover is quasi transient perfect is the fact that the step response looks like a right triangle. Without this feature, the advantages of a transient perfect crossover are lost.

Here is the distortion associated with these measurements and although I am not using the suggested Purifi passive radiators, there is still a fairly low level of harmonic distortion.

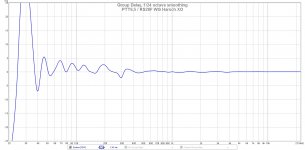

From the measurements, we can also see that the measured group delay (GD) is excellent – under 5 milliseconds down to about 45Hz.

Edit May 21, 2020: New Polar Data (approx angles but distance of 0.5m is correct, mic on woofer axis as designed):

So what we have here is sort of like the elusive missing Chalice of XO’s: a simple quasi-transient perfect higher order XO capable of rendering clean, crisp attack notes while remaining easy to implement in a flat baffle speaker with commercially available drivers and woofers. The PTT6.5 is what makes this speaker possible.

How does it sound? I only have it in mono, but it sounds Excellent: great balance and clarity, nice midrange weight and slam, super highs and a wide sweetspot and excellent imaging provided by the waveguide! I really am impressed by how clean it sounds, and the tweeter is working where it is mostly designed for. This leaves the woofer to handle the midbass, where it loves to operate. The bass with the dual Dayton PR’s still needs work, but this is where I think a TL is going to really do a nice job.

Here is a

video of this speaker playing a song that really exercises the passive radiators. I will need to make a proper TL speaker to keep the high efficiency and low distortion bass output as these passive radiators I had were running out of xmax already.

Edit May 26, 2020:

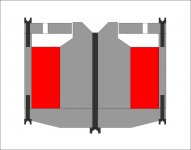

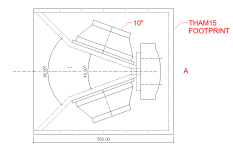

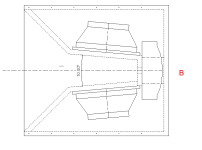

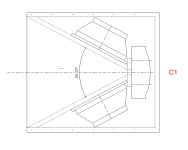

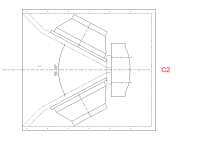

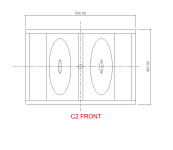

Plans for TL here

Waveguide adapter plate STL file here:

Simple Passive Harsch XO Using PTT6.5 and RS28F in a Waveguide

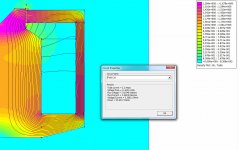

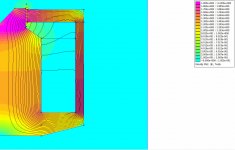

Here is response of TL predicted by Akabak, max SPL is 101dB at 21Vrms (exceeds thermal limit), and SPL at Xdamage is 104dB:

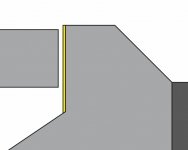

Here are the plans for just the front baffle to make a version with a removable baffle. Remember to removed the 0.75in from the front on the side view of the main plans if going this route.

Simple Passive Harsch XO Using PTT6.5 and RS28F in a Waveguide

Here are CAD files of the TL speaker (STL and STEP):

Simple Passive Harsch XO Using PTT6.5 and RS28F in a Waveguide

Final XO board with flat copper foil inductor and Jantzen and Mills resistors:

BOM for XO here:

Simple Passive Harsch XO Using PTT6.5 and RS28F in a Waveguide

Here is measured response with new permanent XO PCB vs temporary developmental XO:

Edit May 29, 2020: The new RST28F-4 tweeter has been tested and

verified to work with the WG300 waveguide and this speaker. Requires additional felt spaceer between the WG300 and the RST28F faceplate due to a larger grille diameter.

Edit June 14, 2020: Revised plans for the TL with corrected cutout dimensions for the drivers. This plan utilizes a removable front baffle which will simplify installation of the XO board, padding and stuffing. Moreover, it allows you to change the tweeter at a later time. The box can be flipped with the tweeter on top for a conventional LR2/LR4 crossover if desired.

Simple Passive Harsch XO Using PTT6.5 and RS28F in a Waveguide

EditJune 28, 2020: The completed TL speaker in BB ply for some casual listening in the kitchen:

Edit June 29, 2020: Here is the schematic showing the final parts used as shown in the photo of the XO and measurements above:

Edit Aug. 15, 2020: New revised XO for better tonal balance -

more info here:

F3 of 39Hz and slight downward tilt in the response:

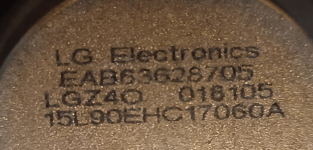

Final XO using Dayton Precision 1% 10W resistors, Jantzen 2.5mH 18ga coil, Dayton 0.5mH 20ga coil, Audyn Q2 22uF MKP for woofer and Dayton Precision 2.2uF MKP 250v 1% for the tweeter. I have a bypass of 0.1uF MKP Dayton as a place holder for a Miflex 0.1uF 600v bypass on the other channel.

Here is the channel with the Miflex, I will see if I can do an AB in mono one of these days:

Edit Mar 23, 2021: I have developed a floorstanding TL. More info

here.