Hello everyone!

Well it's been 10 weeks in the making with a lot of learning along the way, but here I present to you the:

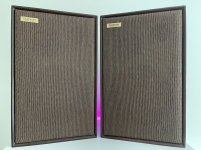

We were given these speakers and narrowly saved them from being taken to the tip. They appeared to have water damage, many dents and scratches, the grilles were torn and ragged and the mids/tweeters were damaged. Liking the look of these older speakers and being drawn in by the 12" woofer, I wanted to do something to save them.

I would like to say a massive thank you to system7 and Galu for all their help and advice along the way, as well as raymondj, planet10 and everyone else who contributed or offered help and suggestions. It would not have been possible without you!

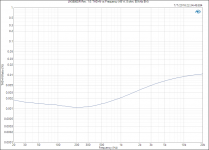

The Goodmans Magnum-K2 is a large (29cmx38cmx61cm) chipboard cabinet 3-way finished in teak veneer and is understandably very heavy. It retailed for £46.20 in 1971 and it's specs are:

Impedance: 4 - 8 ohm

Max. RMS power: 50W

Frequency Range: 30 - 22,000Hz

Sensitivity: 2W produces 96dB in the average domestic listening room

(Thanks Galu for finding the above)

Here is a brochure page for the range of Goodmans speakers at that time (thanks raymondj):

Here is the original thread:

https://www.diyaudio.com/forums/multi-way/374378-restoring-modifying-goodmans-magnum-k2s-advice.html

Modifications

- Crossover redesign (thanks Steve!)

- Relocate crossover to bottom of cabinets

- Upgrade internal wiring (2mm)

- Construct mid enclosure

- Replace mids

- Replace tweeters

- Strip veneer and refinish

- Restore/add black paint on baffle and grilles

- Replace velcro on baffle and grilles

- Replace posts

- Alter the way the bass driver is secured

- Filled various imperfections, especially on the rear of the cabinets

- New gaskets

- Add additional dampening material to the internal walls

- Recover grilles with new foam retro fabric

- Custom grille badge

The above is a summary of the main changes, but I am sure there are other little things I have forgotten.

Replacement Drivers

The mids seemed to have extensive PVA glue on them from some sort of repair, and definitely sounded below par to me. It's possible they sounded as originally intended, but if that was truly the case then I wouldn't rate them very highly. The tweeters may have been ok, but they looked fairly poor cosmetically. We decided to replace them both.

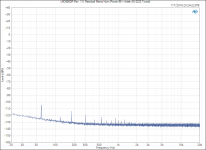

The drivers used are the Faital 5FE120:

and the HifiDIY X1II:

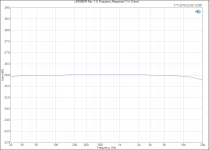

Using this tweeter, the frequency range will improve slightly to 20 - 22,000Hz

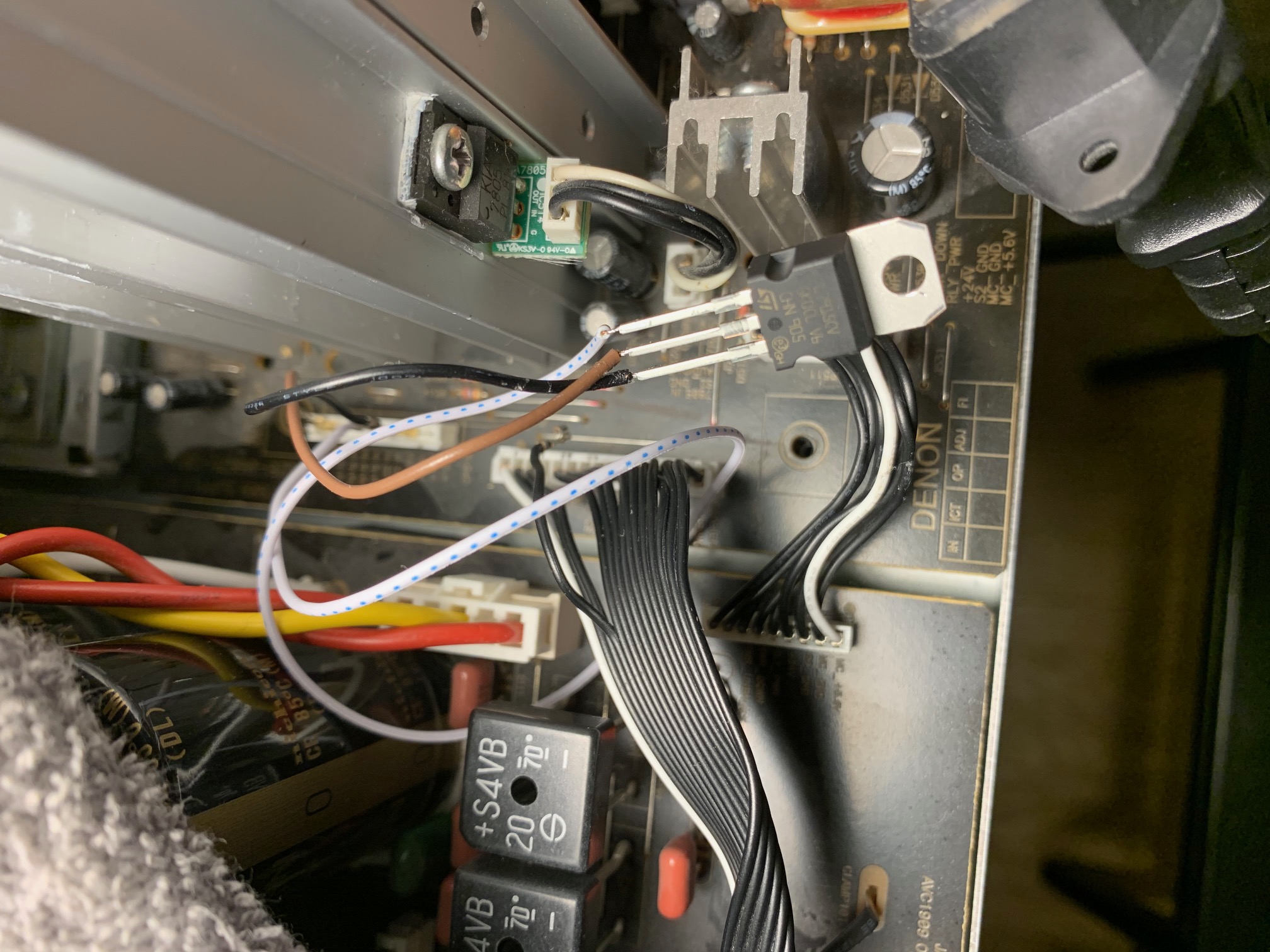

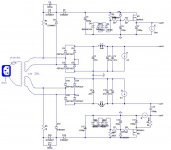

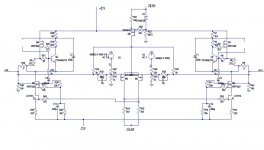

The original crossover looked like this:

It was located on the small piece of removable ply board that the posts are attached to.

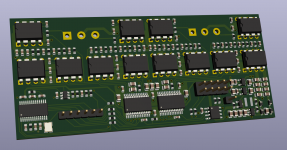

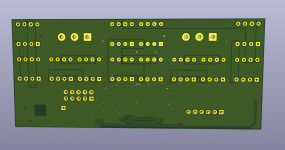

Diagram of original crossover:

Please excuse my rubbish scribbling!

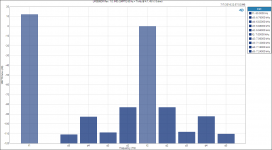

With the help of system7 (and Troels by proxy?

😉), we ended up with this:

Cost

Cost

By all rights, this probably should have cost more. But Freecycle/Neighbours/The Shed yields wonders from yesteryear, a failed project, some spares left over etc. I begged, stole and borrowed quite a large percentage of the materials needed for this, and the total cost ended up being just over £200, I am sure if I had purchased everything it could have easily been double that. By FAR the most expensive components were the Clarity Cap ESAs at half the total. The Faitals were a quarter of it at £51. I am sure this could be done even cheaper still if NPEs were used, the Tweeters weren't replaced and some things were ignored/skipped.

So without any more delay, lets have a look at some:

Build/Process Pictures 🙂

Original cabinets and condition they were received in:

They've seen better days!

Pretty ugly chocolate mousse brown rear panel:

Both drivers looking damaged or worse for wear:

Stripping the cabinets

Stripping the cabinets

Most of the stripping has to be done via the bass cutout. Removing the tweeters was easy. The mids were a little adhered by their very old gasket foam tape but did come out with a little persuasion. From there, you can place your hand in and push the large bass driver from the back. The crossover, wiring and 2 large foam pieces (per cabinet) have to come out via the bass cutout. We did briefly consider altering the cabinet so the back was removable, but in the end it seemed like it would be too much hassle and needlessly weaken what is a very strong cabinet. You can see that the teak veneer has a very red colour to it, and that the baffles were a very faded black. There were a large amount of staples that needed removing (from the velcro strips) this was not fun!

Because they were obviously allowed to get damp at some point, the LARGE amount of foam in the cabinets had a VERY strong musty smell. They were in the house when we first got them, and coming downstairs in the morning was a little unpleasant. We quickly moved them to the garage. We treated the foam with vast amounts of bicarb and a good airing on sunny days.

Here we had sanded the veneer (something which we later found out you SHOULD NOT DO!) and the baffles in prep for painting them black:

We also sanded the awful chocolate mousse brown backs which were just painted chipboard and filled a lot of bumps and dimples in the chipboard round the edge:

[url=https://ibb.co/D4kZnrq]

We also noticed when removing the bass drivers, that there was some corrosion to the metal at the rear of the drivers:

We didn't want this to continue so we used some hammerite on it:

Painting/Dying

Painting/Dying

One of the things that we wanted to do was get rid of the red wood. Neither myself or the wife are particularly fond of red wood, so a darker brown was chosen. We started off using an acrylic based paint to paint the veneer. This ended up looking absolutely awful:

It wasn't a problem to remove, though! It peeled straight off!

We changed course, and went for a dye this time. To start with, we stripped back the cabinets as much as we could and bleached them:

[/url]

We started applying Littlefair's wood dye (a fantastic product) and this was all going very well....

UNTIL... we waxed it:

Total lack of experience on our part, but the wax ruined what

had looked rather nice. It wrecked the finish and made it look patchy and awful and to our surprise (despite the bleaching) showed a lot of the original red!

At this point we honestly thought it was game over! I contacted the company who made the dye for advice and they said that not only should be not have sanded the veneer (scrape off the excess wax and clean) but they would finish it with a dye mixed with polyurethane and acrylic. They said all the wax would have to come off first and gave some advice on how to do this.

Copious amounts of white spirit to dissolve the wax, then (if it will take it) washing up liquid and water plus LOTS of kitchen roll. We used the white spirit and were pleased, then moved onto the washing up liquid. This was causing some issues and we decided that it was getting too wet (something we had been warned about). Thinking that things couldn't possibly get any worse, we used citrus Swarfega with grit in it as it's more like a paste, strips oil based products and contains citrus which is a good cleaner... and..... this did the trick:

We lightly scrubbed it with an old nail brush and you can see how much is coming off on the kitchen roll:

And after applying the new dye with polyurethane and acrylic in:

Dyed, varnished and protected in one! We applied this one sparingly with a cloth in several layers. Phew!

We used this dye and varnish combo on the backs to get rid of the horrible brown:

Finally, we used black acrylic spray paint for the back of the grilles and the baffles:

The baffles and were given several coats of clear polyurethane varnish as well as the yellow paper the posts are sat on.

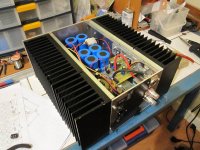

Mid enclosure / Driver Replacements / Crossover

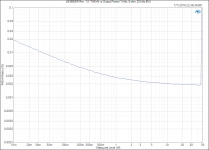

The Faital 5FE120 required about a 5L enclosure.

View from bass cutout:

We started by using a cardboard box to see what size MDF we would need to get from the shed:

Then cut several peices BUT we had to assemble them inside the cabinet, which was

lots of fun

😛

Done!

We fixed in place and sealed with a LOT of hot glue and liquid nails:

This presented a problem... the way to secure the bass driver was to put your hand in through the mid cutout and use a stubby screw driver to hold the inverse facing screws/bolts whilst tightening them from the front with a spanner or socket. So remove this issue, we used liquid nails to fix small chunks of MDF behind each screw hole so that we could secure the driver from the front:

The cutouts were too small for the replacement drivers. Not by much, but the original Goodmans mid was 4" and the new Faital is 5".

The tweeter (which I got cheap from a friend who ordered the wrong size) would technically fit, but when I got it I found the spade connectors stuck out a little. The tweeter cutout would need a couple of notches to allow the connections to sit without being mangled. We had to make these notches top and bottom as opposed to left and right because the mid enclosure would be in the way:

Mid cutout increased:

Of course, the cutouts in the grilles would have to be increased and the black paint touched up:

And here's some of the grilles being refoamed:

https://ibb.co/2gX9D4R

https://ibb.co/2gX9D4R

I got given some 5mm grey foam (for upholstery?) and we just used PVA to adhere it to the board once they were sanded off:

[/url]

Cutting foam is not easy without tearing it!!

The grille fabric we ended up using I also got given:

We love the retro look of it, and think it matches the darker dyed veneer. I’ll save pics of this on the grilles for the end

🙂