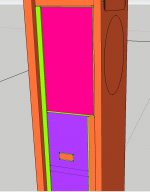

The small box for the woofer is Q .707. All the edges will be rounded over. Also I didn't put it in the images above but I'll likely have another brace in the top compartment that houses the waveguide and CD.

Also the very bottom panel will be attached to the outer panel walls. It will be two pieces of ply, a visco elastic layer and above that will be the bottom panel of the inside cabinet.

Also the very bottom panel will be attached to the outer panel walls. It will be two pieces of ply, a visco elastic layer and above that will be the bottom panel of the inside cabinet.

Last edited:

Not sure if you can tell what's going on here, but at the bottom there is an extra section of the orange layer. This is so that I can screw my front baffle onto it, allowing the front (and rear) baffles to be removable. Which allows access to the drivers.

The woofer will be surface mounted on the fuchsia box. and then the orange front baffle will have a roundover that will transition it onto the front baffle. Visco elastic layer between.

The woofer will be surface mounted on the fuchsia box. and then the orange front baffle will have a roundover that will transition it onto the front baffle. Visco elastic layer between.

Attachments

Nice project! Agree that a standmount speaker would be easier/cheaper to build all things considered.

As for edge diffraction due to a lack of roundover, I doubt this would be much of an issue due to the directivity control of the waveguide. It couldn't hurt though. Would be interesting to do before and after roundover measurements at 0,15,30 degrees if possible.

The woofer will not be prone to diffraction due to its limited dispersion above the crossover frequency (the cabinet diffraction should start around 1.5kHz).

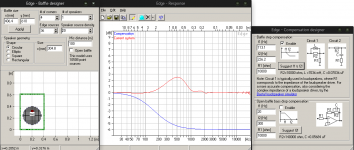

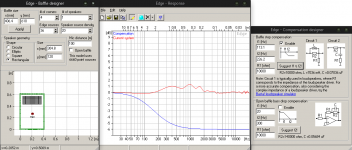

Simplistic models from "The Edge" attached...

As for edge diffraction due to a lack of roundover, I doubt this would be much of an issue due to the directivity control of the waveguide. It couldn't hurt though. Would be interesting to do before and after roundover measurements at 0,15,30 degrees if possible.

The woofer will not be prone to diffraction due to its limited dispersion above the crossover frequency (the cabinet diffraction should start around 1.5kHz).

Simplistic models from "The Edge" attached...

Attachments

If the bottom half serves no acoustical purpose to the speaker, then why even have it? Just make the top half and use a stand. Much easier to make.

I think the main reason was that based on the dimensions the speaker looked ugly/awkward as a stand mount. Whereas the floor stander may blend in with the corner bookshelves. I don't like seeing my equipment. The more it can blend in with the furniture the better.

Also I was thinking (tell me if I'm wrong) that if I had larger panels for CLD that there would be more energy dissipation. I also thought that a larger front baffle would control the wave better.

It does seem a bit superfluous otherwise.

Shawn

I think the main reason was that based on the dimensions the speaker looked ugly/awkward as a stand mount. Whereas the floor stander may blend in with the corner bookshelves. I don't like seeing my equipment. The more it can blend in with the furniture the better.

Also I was thinking (tell me if I'm wrong) that if I had larger panels for CLD that there would be more energy dissipation. I also thought that a larger front baffle would control the wave better.

It does seem a bit superfluous otherwise.

Shawn

I would make them two cabinets then and decouple them from each other. (I have done this with my speakers in the past.) Then the lower cabinet does not need any bracing or CLD. Smaller panels are always better for lower sound radiation, CLD or not.

Then that's what I'll do. Thanks.

What's a practical method to decouple?

You're planning on decoupling your front baffle right?

You're planning on decoupling your front baffle right?

No, I think the front baffle will be CLD....?

Am I doing this wrong? Should I be adding CLD on the inside and then a decoupled baffle on the outside?

No, I think the front baffle will be CLD....?

Am I doing this wrong? Should I be adding CLD on the inside and then a decoupled baffle on the outside?

My point was, CLD is a method to decouple, so you could at least start with the same method you're using for the front baffle.

But generally speaking, rubber works great for decoupling, some rubber feet between the top enclosure in the bottom stand would certainly do a lot to decouple the two.

Javad

Then that's what I'll do. Thanks.

What's a practical method to decouple?

Most practical is just a sheet of rubber. More effective would be a CLD layer made of several stacked pieces.

Am I doing this wrong? Should I be adding CLD on the inside and then a decoupled baffle on the outside?

The front baffle should be CLD, but decoupling the driver from the baffle can have both positive and negative effects that only experimentation could determine. I have found it best not to risk decoupling the woofer, just use CLD on the baffle.

My point was, CLD is a method to decouple, so you could at least start with the same method you're using for the front baffle.

Javad

I would not consider CLD to be a method of decoupling. To me the two things are different.

I would not consider CLD to be a method of decoupling. To me the two things are different.

Interested to know your thoughts, dampening and decoupling are very similar concepts as related to reducing vibration. If CLD can be used to decouple a baffle from the enclosure, it could certainly be used to decouple an enclosure from a speaker stand.

I think the main reason was that based on the dimensions the speaker looked ugly/awkward as a stand mount. Whereas the floor stander may blend in with the corner bookshelves. I don't like seeing my equipment. The more it can blend in with the furniture the better.

Also I was thinking (tell me if I'm wrong) that if I had larger panels for CLD that there would be more energy dissipation. I also thought that a larger front baffle would control the wave better.

It does seem a bit superfluous otherwise.

Shawn

I had a similar idea with the boxes I made for AEs TD12 M as mid bass plus a Beyma TPL 150H for frequencies above 1300-1500 Hz. A 100 cm / 39,5“ high cabinet with 3 sealed off compartments, where the lowest one only works as a an integrated speakers stand to get the elements at appropriate listening height. (And if I move I can open up the 3 compartments into one to get a dual purpose cabinet for a possible ported speaker, tuned to about 60 Hz. Current subs are hard to bring along if I move.) Another reason was that the disadvantage of a heavier 1 piece cabinet turns into an advantage if you wish to decouple the cabinet vibrations (isolate) from the room structure so it does not rattle along when you play music with low frequency content. -It is so much easier to find good quality industrial vibration dampers and be able to reach a very low natural resonance frequency for a somewhat heavier box, say 36 kg / 80 lbs and up. For light weight speakers it’s hard to find good stuff that can isolate down to below 30 to 20 Hz and lower. You need a certain amount of load / damper and possible deflection in mm to isolate low frequencies.

As your compartment for the 12” Dayton is quite small, I doubt you will have much, if any, low frequency resonances from it. The elasticity module / shear strength for Green Glue is (as far as I know) “very low” so it works well for CLD in walls / large panels versus low frequencies. Possible cabinet resonances for a small compartment will more be in upper bass to midrange / treble, so a non hardening glue with higher elasticity module (“stronger”) would be more suitable to dampen those frequencies. You can check up patents on CLD constructions with “Quiet Glue” and MS polymers from various manufacturers. The lower strength ones are better for low frequency damping, the higher strength ones for midrange and up. (I have copies somewhere, just have to find them again … )

I could be wise to construct the cabinet volume for Qtc 0,6 or so, instead of 0,707. With rising temperature in the spool and inside cabinet the Qtc will rise. You can always later decrease a larger internal volume with a block of some kind or beef up the thickness of the inside of the back piece if you decide that. Making an existing internal volume larger is a bit trickier …

I used an MS polymers from Henkel Loctite (Terostat 930 and 939) for the CLD in my cabinets. MS polymers has a dry content of 98-99% while water and acrylic based ones like Green Glue, Quiet Glue or Swedacs DG-A 2 has a dry content of 65-68%. This can be of importance if you insert 1 mm / 1/32” thick wooden shims between your sheets to get a correct glue thickness and shims are left inside the sheet sandwich. –The roughly 33% water content will evaporate with time, so the result can be resonating air pockets between the sheets. You don’t want that, with higher dry content you run a smaller risk of air pockets with shim sleft inside the sandwich

A good shear strength to look for, for the non hardening glue you use for the CLD would be about 1 MPa (1 N/mm²).

Besides the CLD I also used some further "overkill" to dampen cabinet vibrations, a kind of "floated installation" of the drivers with viton o-rings and shims together with machine screws in slighly oversized holes, plus for decoupling industrial grade vibration dampers as speaker feet.

(With CLD you have little to no control whatsoever of the frequencies you don't want to go into the room structure. It is quite easy to "tailor make" that with vibration dampers though, just by checking up the published info and diagrams from manufacturers. And I don't mean the expensive hifi / audiphool stuff now.)

Last edited:

Interested to know your thoughts, dampening and decoupling are very similar concepts as related to reducing vibration. If CLD can be used to decouple a baffle from the enclosure, it could certainly be used to decouple an enclosure from a speaker stand.

Both reduce vibration but in different ways. CLD is pure damping, it does not decouple anything from anything. A CLD baffle is not decoupled from the enclosure, it is simply heavily damped. Decoupling is the procedure of preventing transmission of vibration from one location to another, it does not necessarily exhibit damping, although damping is often used. An engine mount is the classic decoupler. CLD could not be used in this application at all. CLD applies only to panels as a method of damping them - it can be shown to be the most effective method at this. Its operation is purely in the bending of a panel and the net strain on the median layer.

CLD (constrained layer damping) between 2 MDF sheets. The middle layer of non hardening glue is put under strain/stretch as the cabinet vibrates out and inwards and is "stopped" by the stiffer MDF sheets. When that happens vibration energy (movement) is transformed into heat in the soft layer. Result: Less movement / vibrations goes out into the room from the outer layer of MDF. A lot more efficient kind of damping than adding a second layer of bitumen / roofing felt onto a singular MDF sheet

Decoupling, here vibration dampers are of a hollow rubber ball type, vulcanized to a steel flange. Load them with correct max weight on top (according to manufacturers specifications) and it will reach its own lowest possible resonance frequency with at the same time maximum deflection without collapsing (bottoming out). If that resonance frequency is, say, 20 Hz no frequencies from the cabinet above 20 x (root 2) = 28 Hz can pass further into the structure (floor) but will be effectively isolated.

Load it with unnecessarily too light a load and the rubber ball can be seen as "stiff" which results in a higher own natural resonance. Too high a load so it bottoms out, can also be seen as "stiff" with worse decoupling / isolating properties. You want to be close to the "floating condition" which means a speaker that wobbles a bit if you give it a push with your hand. If the speaker cabinet is very heavy compared to the cone weight, the cabinet will not move much back and forth due the cones acceleration back and forth. (It does not take that much to constrain the rocking though if one is anal about it.) With a "light speaker" and a "heavy cone", the rocking movement will be higher of course.

To reach extremely low resonance frequencies, metallic springs would be used instead of elastomers. The vibrations dampers I use will get a resonance of around 14 Hz (9 kg load / damper and 5 of them versus a speaker weight of 44,5 kg.) So, isolation from 20 Hz and up. That gives a good margin, more than 2 octaves, as this speaker shall be crossed over to separate subs at around 110 Hz.

Both reduce vibration but in different ways. CLD is pure damping, it does not decouple anything from anything. A CLD baffle is not decoupled from the enclosure, it is simply heavily damped. Decoupling is the procedure of preventing transmission of vibration from one location to another, it does not necessarily exhibit damping, although damping is often used. An engine mount is the classic decoupler. CLD could not be used in this application at all. CLD applies only to panels as a method of damping them - it can be shown to be the most effective method at this. Its operation is purely in the bending of a panel and the net strain on the median layer.

Gotcha thanks for the reply.

I certainly didn't say CLD and decoupling were the exact the same thing as you're possibly reading, however I do believe either would work for his purpose to reduce vibration transfer to the base. I also suggested rubber feet which is what I would use.

I've had good results using feet like these: https://www.parts-express.com/peavey-large-rubber-feet-1-1-2-dia-x-3-4-tall-set-of-4--248-8786

Also Mcmaster has some interesting options: http://www.mcmaster.com/#rubber-mounts/=12dt5m7

HTH!

Last edited:

Gotcha thanks for the reply.

I also suggested rubber feet which is what I would use.

I would try an avoid a gap between the two cabinets as this would be a major diffraction point, which is why I suggested a rubber sheet.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- SEOS / Dayton 2 way