Also I am going to place the new order probably today. So...

Dayton PA310-8

Dayton D250P

SEOS-12

My only concern right now is vertical polars. I'd like the speakers to have even directivity whether I am lounging on the couch or standing up in the kitchen behind the couch. Is this realistic or with this system am I aiming for one or the other?

You should be able to get a nice good sized forward lobe, but there will be cancellation notches. Aiming one (notch) at your knees on the couch should give you a reasonably tall vertical window that will cover the couch and kitchen.

Also I am going to place the new order probably today. So...

Dayton PA310-8

Dayton D250P

SEOS-12

My only concern right now is vertical polars. I'd like the speakers to have even directivity whether I am lounging on the couch or standing up in the kitchen behind the couch. Is this realistic or with this system am I aiming for one or the other?

If that's the case you should look at coaxial systems...either the B&C or Faital Pro 8" drivers would work wonders. Or go Synergy horns. ;-)

Speaker Driver Displacement Calculator

If you need a ballpark, take a look at this (it suggests 12" driver displaces 0.07 ft^3).

http://www.bcae1.com/spboxnew2.htm

If you need a ballpark, take a look at this (it suggests 12" driver displaces 0.07 ft^3).

http://www.bcae1.com/spboxnew2.htm

Last edited:

Thanks,

I ordered the drivers. I'm just modelling the boxes. Is there anything I need to know about nulls? Like vertical nulls? Or can all these things be adjusted electronically?

I assume I just keep the SEOS and the 12" close together..

Is there any benefit to widening the baffle, will it increase directivity? Or can it be fairly narrow with a good round over?

I ordered the drivers. I'm just modelling the boxes. Is there anything I need to know about nulls? Like vertical nulls? Or can all these things be adjusted electronically?

I assume I just keep the SEOS and the 12" close together..

Is there any benefit to widening the baffle, will it increase directivity? Or can it be fairly narrow with a good round over?

Vertical spacing can produce nulls at the extremes when it is larger. Horns make close vertical spacing more difficult, but on the other hand when directivity is already dictating less output at the extremes, you can space a little further.

There are a number of things going on here and crossover design is a little complex. You can adjust the ratio of power to direct sound pressure by varying the phase difference between the drivers, at the expense of the angle of the lobe, which if not for this, should ordinarily be pointed forward.

Your cabinet width is going to contain the low end so there is something to be said about holding this to the room frequency, but it's not essential. I just think it makes things easier. A good roundover is a good thing, especially at middle and higher frequencies.

There are a number of things going on here and crossover design is a little complex. You can adjust the ratio of power to direct sound pressure by varying the phase difference between the drivers, at the expense of the angle of the lobe, which if not for this, should ordinarily be pointed forward.

Your cabinet width is going to contain the low end so there is something to be said about holding this to the room frequency, but it's not essential. I just think it makes things easier. A good roundover is a good thing, especially at middle and higher frequencies.

Thank you. And I just want to say thank you so far and in advance for all the guys helping me here. If I don't respond to your message it usually means I understood it. And always appreciate it. I just don't know what the etiquette is on forums for this type of thing. I assume it would take up too much space to respond to each message. Maybe I am being too Canadian.

Got the drivers in today. I've never had a 12" woofer before. This thing is a mammoth.

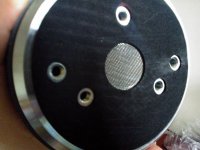

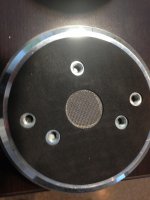

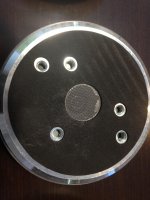

One of the compression drivers has some kind of film or something on the front metal mesh. It is kind of sticking in from the edges around the circular exit and 'is one' with the mesh. The other driver is perfectly fine, just mesh.

Has anyone seen this before? Is it worth returning?

I'm having trouble posting pics. My phone doesn't want to make friends with my computer.

One of the compression drivers has some kind of film or something on the front metal mesh. It is kind of sticking in from the edges around the circular exit and 'is one' with the mesh. The other driver is perfectly fine, just mesh.

Has anyone seen this before? Is it worth returning?

I'm having trouble posting pics. My phone doesn't want to make friends with my computer.

When designing front baffle size. If Edge sim says I drop by 4db from 350hz to 100hz, how bad is this? Can I make up for it with digital equalization? Does this demand more from the amps? When does it become a bad issue, what about if 5db down?)

This is deciding whether I make a bookshelf or floorstander. I would prefer a (large) bookshelf.

btw these will likely high-pass around 100hz. Fc of enclosure is 95hz.

This is deciding whether I make a bookshelf or floorstander. I would prefer a (large) bookshelf.

btw these will likely high-pass around 100hz. Fc of enclosure is 95hz.

Last edited:

That film is at the critical throat. The worst place to have an obstruction. Maybe you can peel back the gasket and carefully lift up the screen and pick off the plastic film with good tweezers. I would normally return them but you mentioned having horror stories with all the back and forth with PE and being in Can doesn't help. What compression drivers are those?

They are Dayton D250P. I got them from Solen so it will hopefully be a little easier to return as they're in Canada... I may just return them. I specifically asked for a visual inspection to be done too. As you know I'm having no luck ordering drivers. lol.

What do you think? Return it or no?

What do you think? Return it or no?

BTW here are pics of the compression drivers.

Return....that'll definitely mess up the wave-front leaving the driver.

(Edit: Unless you can clean out...but I don't think you can isolate that mesh from the driver without damaging it...there is a planer wavefront that leaves that exit...it needs to be intact without diffraction or your HF will be all messed up.)

Is there an around the house solvent y'all can think of that on a q-tip might be able to dissolve it.... mind you it would probably dissolve the gasket too. p.o.s.

Out of curiosity, how come the mesh doesn't mess up the wave front?

It does....but not in the audible range. The dimensions of the wire are too small to be a sizable portion of a wavelength even at high frequency.

1/4 wavelength at 20kHz. is .169"...so things substantially smaller than that are relatively invisible. It's like putting a string in front of a subwoofer...vs. a couch. (simplified...but you get the point.)

I bought open cell, reticulated, PU foam at a foam shop. They had it in stock to sell to folk with garden ponds - it's used as a filter and culturing medium. Its about 30 ppi. So a place providing garden pond supplies might be a place to look if a foam shop don't have it. Also, the kind of foam you want is also used to upholster outdoor and marine furniture cuz the h2o goes straight thru.

If somebody sells open cell foam as an acoustic filter you can be sure they'll charge more than pond supply or outdoor upholstery suppliers.

@ 30 ppi is fairly common.

Yeah, use the foam in the waveguide and you can take out the bug screen in the driver.

If somebody sells open cell foam as an acoustic filter you can be sure they'll charge more than pond supply or outdoor upholstery suppliers.

@ 30 ppi is fairly common.

Yeah, use the foam in the waveguide and you can take out the bug screen in the driver.

Thanks Frank! I was wondering that very thing.

I found a place nearby that has the stuff for marine upholstery, it's 33ppm. And they can cut it for me too. I heard back from Solen today and apparently their whole stock is like that! They sent me pictures and some are worse then mine. I see why some people stick to the B&C DE250 for quality control instead of these knockoffs.

I will have to get crafty to take the mesh off... the gasket material is on there snug. I am going to try lightly touching the film with a solvent on a Q-tip or toothpick first.

I found a place nearby that has the stuff for marine upholstery, it's 33ppm. And they can cut it for me too. I heard back from Solen today and apparently their whole stock is like that! They sent me pictures and some are worse then mine. I see why some people stick to the B&C DE250 for quality control instead of these knockoffs.

I will have to get crafty to take the mesh off... the gasket material is on there snug. I am going to try lightly touching the film with a solvent on a Q-tip or toothpick first.

Thanks Frank! I was wondering that very thing.

I found a place nearby that has the stuff for marine upholstery, it's 33ppm. And they can cut it for me too. I heard back from Solen today and apparently their whole stock is like that! They sent me pictures and some are worse then mine. I see why some people stick to the B&C DE250 for quality control instead of these knockoffs.

I will have to get crafty to take the mesh off... the gasket material is on there snug. I am going to try lightly touching the film with a solvent on a Q-tip or toothpick first.

Huh...I've purchased three of those tweeters....none of mine had that. Yikes...

If you put the 30PPI reticulated foam in front you can pull them off...no worries. The rub and buzz from a dead bug is no good.

Solen pics

Here are 3 of the pictures they sent me. I am starting to wonder if it is actually the same metal that makes the mesh... It quite hard to tell with the naked eye and a flashlight.

Here are 3 of the pictures they sent me. I am starting to wonder if it is actually the same metal that makes the mesh... It quite hard to tell with the naked eye and a flashlight.

Attachments

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- SEOS / Dayton 2 way