here is one of them http://headfonz.rutgers.edu/RDH4/CHAPTR05.PDF see if it helps you.if not i'll search some more or you can by google "interleaved winding". jer p.s. i have the whole book down loaded great info there

Last edited:

Hi, is there anyone that have a description/suggestion/opinion on how windings should be interleaved?

Primary2

Secondary

Primary

Core

Primary

Secondary

Primary2

With the primaries in secondary seems to be the easiest approach.

Regards

Bent

As kavermei mentioned earlier in this thread, the amount of interleaving depends on what your design goals are for your transformer.

To determine how much and what type of interleaving is needed you need to define what you want your transformer to do.

1) What is the core area? ( i think you may already have chosen a core)

2) How low do you need the transformer to operate? is this for full range use? or hybrid?

3) What is the maximum expecting input voltage?

These 3 items will determine the required number of primary turns.

4) What step up ratio are you wanting? (this defines number of secondary turns)

5) What is the capacitance of your panels? and are your panels segmented or not? This will help define the allowable leakage inductance before you start affecting your high frequency response.

6) Do you plan to use 1 transformer to drive both stators? or two transformer with secondaries in series, primaries in parallel. This can change to way you do interleaving to minimize interwinding capacitance.

As Calvin has mentioned many times on the forum, sticking with hybrid designs and lower step-up ratios, the transformer design becomes much easier.

You may not even need any interleaving at all.

Last edited:

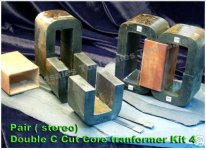

C-core transformer kits on ebay

Just noticed these M6 C-core transformer kits on ebay from Hong Kong based seller: Toolsales

eBay My World - toolssales

If I read the description correctly, the prices are for materials for a pair of transformers.

Perhaps this will be of interest to some of you.

Push pull single end Audio output transformer core kit1 - eBay (item 260504023039 end time Mar-09-10 01:07:43 PST)

Push pull single end Audio output transformer core kit2 - eBay (item 250527664593 end time Mar-09-10 01:07:09 PST)

Push pull single end Audio output transformer core kit3 - eBay (item 250527658399 end time Mar-09-10 00:41:00 PST)

Tube Audio output transformer Double Cut Core kit 4 - eBay (item 250542403072 end time Apr-03-10 00:07:34 PDT)

Just noticed these M6 C-core transformer kits on ebay from Hong Kong based seller: Toolsales

eBay My World - toolssales

If I read the description correctly, the prices are for materials for a pair of transformers.

Perhaps this will be of interest to some of you.

Push pull single end Audio output transformer core kit1 - eBay (item 260504023039 end time Mar-09-10 01:07:43 PST)

Push pull single end Audio output transformer core kit2 - eBay (item 250527664593 end time Mar-09-10 01:07:09 PST)

Push pull single end Audio output transformer core kit3 - eBay (item 250527658399 end time Mar-09-10 00:41:00 PST)

Tube Audio output transformer Double Cut Core kit 4 - eBay (item 250542403072 end time Apr-03-10 00:07:34 PDT)

Attachments

Hi, I will test and report.

I realized that driving my coilwinder with a powerdrill was to uneaven in speed, so I ordered a complete machine from Hong Kong that was cheaper than buying a powersupply and geared motor.

Maybe I can use it to wind fishing line onto my fly fishing reels later ;-)

Regards

Bent

I realized that driving my coilwinder with a powerdrill was to uneaven in speed, so I ordered a complete machine from Hong Kong that was cheaper than buying a powersupply and geared motor.

Maybe I can use it to wind fishing line onto my fly fishing reels later ;-)

Regards

Bent

Hi, I will test and report.

I realized that driving my coilwinder with a powerdrill was to uneaven in speed, so I ordered a complete machine from Hong Kong that was cheaper than buying a powersupply and geared motor.

Maybe I can use it to wind fishing line onto my fly fishing reels later ;-)

Regards

Bent

I'm thinking of rebuilding a sewing machine, slow in rpm and with foot pedal..

No counter is needed, I always make my trannys with non-interleaved sections, adding or subtracting secondary turns for a given output voltage...

It's alive! Resurected after 7 years and still sounds fricken awesome! proof that a toroidal power transformer with a custom wound primary works.now all i need is a bigger amp. jer

What is alive?

thanks wachara.right now i cobbled from an old marantz crossover that said the woofer was at 700hz ,it a 4 ohm driver so it is cutting off about 1.7khz, and i have 25 uf capacitor in series with a 10 turn primary.it starts coming in at about 450 hz on the esl.

It is a bit low for a 10 turn winding and the amp doesn't like it on some peaks and shuts down.however it gets comfortably loud at full volume.

my db meter is not working at the moment,but im sure it is around 100db or so at 4' to 6' at full volume.enough to make it difficult to carry on a conversation acroos the room at 10 feet and thats just one esl and woofer at the moment.

i'll do some tweaking tomorrow as it took an 11 ohm resistor to pad the woofer down so that they where close but still not quite the same volume.but you sure could tell a big difference when the esl wasn't playing.

i have a pretty good ear when it comes to flatness and with no eq they were as flat as my little sony ss-mb150h's that i have been using except for the extended bass that 8" sub puts out.

in one word "wow" the clarity was night and day. I listened to all types of material on you tube and as you know some of it is terrible and with so much detail alot was not worth listen too.

I now have them each on there own amp and will do some more tweaking tomorrow. jer

It is a bit low for a 10 turn winding and the amp doesn't like it on some peaks and shuts down.however it gets comfortably loud at full volume.

my db meter is not working at the moment,but im sure it is around 100db or so at 4' to 6' at full volume.enough to make it difficult to carry on a conversation acroos the room at 10 feet and thats just one esl and woofer at the moment.

i'll do some tweaking tomorrow as it took an 11 ohm resistor to pad the woofer down so that they where close but still not quite the same volume.but you sure could tell a big difference when the esl wasn't playing.

i have a pretty good ear when it comes to flatness and with no eq they were as flat as my little sony ss-mb150h's that i have been using except for the extended bass that 8" sub puts out.

in one word "wow" the clarity was night and day. I listened to all types of material on you tube and as you know some of it is terrible and with so much detail alot was not worth listen too.

I now have them each on there own amp and will do some more tweaking tomorrow. jer

Hi Jer,

That's pretty loud. At the loudness, I guess your amp must be clipping a bit.

I've just bought a 300 watts Class D amp to try with my ESL. I hope that I've come to an end for searching the right amp. All I know is that ESL really can suck up a lot of amp power.

Wachara C.

That's pretty loud. At the loudness, I guess your amp must be clipping a bit.

I've just bought a 300 watts Class D amp to try with my ESL. I hope that I've come to an end for searching the right amp. All I know is that ESL really can suck up a lot of amp power.

Wachara C.

the amp usely shuts down when it clips or overloads from the transformer saturating or a very low impedence.It will tolerate 6 ohms but hates 4 ohms.so i never actualy heard any clipping.

my next project will be a better amp. i have five lm4780'S (dual lm 3886)and doing a parallel configuration of maybe 4 per side to deal with the low impedence to get by with for right now,and in the future maybe a lm49811 running a full 200v to get a real voltage swing to compensate a lower transformer ratio as a 30 turn primary gives me a more manageble impedence range.

Right now with a 10 turn primary i have 1:128 ratio and anything less like a 30 or 40 turn primary( 1:32,1:41) greatly suffers in loudness, even though i can go with a lower crossover(which i prefer).

20 turns is quite manageable with this amp,but 6 db less is still 6db less, as it only produces a 37v to 40v signal.

Parallel chip amps should be able to supply the current and posibly a bridge parallel configuration with 8 to 12 lm3886's.

An 80v peak signal would probably suffice with a bigger core to handle the power.

Comperimizes,Comperimizes! jer

my next project will be a better amp. i have five lm4780'S (dual lm 3886)and doing a parallel configuration of maybe 4 per side to deal with the low impedence to get by with for right now,and in the future maybe a lm49811 running a full 200v to get a real voltage swing to compensate a lower transformer ratio as a 30 turn primary gives me a more manageble impedence range.

Right now with a 10 turn primary i have 1:128 ratio and anything less like a 30 or 40 turn primary( 1:32,1:41) greatly suffers in loudness, even though i can go with a lower crossover(which i prefer).

20 turns is quite manageable with this amp,but 6 db less is still 6db less, as it only produces a 37v to 40v signal.

Parallel chip amps should be able to supply the current and posibly a bridge parallel configuration with 8 to 12 lm3886's.

An 80v peak signal would probably suffice with a bigger core to handle the power.

Comperimizes,Comperimizes! jer

Sewing machine

Hi,

yes I was thinking the same thougth, but did not have a old sewing machine at hand.

But, I will rather spend my time building my electrostats and transformer than using a lot of time building tools for the job. My winding machine arrives from China in 4-5 days and then I am ready to make som transformers.

It will be a international transformer, made by parts from Hong Kong (cores), Germany(copper wire and bobbins) and USA for insulation wrap.

Bent

I'm thinking of rebuilding a sewing machine, slow in rpm and with foot pedal..

No counter is needed, I always make my trannys with non-interleaved sections, adding or subtracting secondary turns for a given output voltage...

Hi,

yes I was thinking the same thougth, but did not have a old sewing machine at hand.

But, I will rather spend my time building my electrostats and transformer than using a lot of time building tools for the job. My winding machine arrives from China in 4-5 days and then I am ready to make som transformers.

It will be a international transformer, made by parts from Hong Kong (cores), Germany(copper wire and bobbins) and USA for insulation wrap.

Bent

Hi,

I ordered one off the smallest u-cores...and a automatic coil-winding machine as well! (Stops at preset turns count)

I just wonder how I can smuggle this into the house without my girlfriend finding out!

Regards,

Bent

Tell her you will make a small business out of it and earn lots of money

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- Step-up transformer design