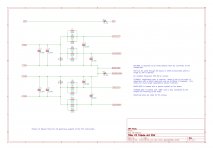

I'm planning to use a single power transformer for a stereo amp with dual bridges, snubbers, and CLC supply. The 2nd set of caps will be split for each channel using the boards in the pix.

Question: Will a single 300VA 18+18V Antek be sufficient?

Question: Will a single 300VA 18+18V Antek be sufficient?

Attachments

I'm planning to use a single power transformer for a stereo amp with dual bridges, snubbers, and CLC supply. The 2nd set of caps will be split for each channel using the boards in the pix.

Question: Will a single 300VA 18+18V Antek be sufficient?

If you are planning to bias at 180mA per channel like is suggested, I would go with a larger (at least) 400 VA and quad secondaries. Searching Antek's site, I don't see one close to the right voltages until you get to the 800VA with 4 each 20 VAC secondaries. Which is what I used and with my highish SIT right at 4.05 Vgs was over the limit of the of the circuit's biasing with only one channel hooked up.

It would be a lot better to use two 200VA Anteks at 18 VAC, like ZM says. (Or if you already have one 300 VA, buy one more for $41.) You can power each tranny individually, so trouble shooting each channel is less hassle.

Cost difference is only $23 USD and you can stack them using a longer bolt.

Thats what I would do if buying new for this project.

By the way, it is the best sounding amp in my stable at the moment. So worth the little bit extra to do it right.

Rush

sound?

Ok, quick test with fully warmed up amp. First thoughts were huge amount of details and sort of ”black” backround, it’s hard to descripe. I don’t have M2 around now to compare.

Speakers 6ohm nominal that falls way below 4ohm and M25 drives them without a hiccup

Yes, it definitely was worth the trouble.

Thanks Chede & ZM. I understand a little bit about the implications for the preamp seeing different input impedance, but what about the amp? Does changing R2 change the sound in some way?

With capacitors on my preamp's outputs, the higher impedance lets me save a lot of money by buying much smaller uF caps...

With capacitors on my preamp's outputs, the higher impedance lets me save a lot of money by buying much smaller uF caps...

That's great news ZM. Do you know if that's also true of the F4? It's got a 47.5k resistor at R2 and 2uF film caps are crazy expensive. Would love to swap that out too.

Can you tell me what drives those decisions? In looking at the FW offerings, Nelson's input impedance moves around quite a bit, but this discussion makes it a bit unclear to me why that's the case. Thanks for the education...

Can you tell me what drives those decisions? In looking at the FW offerings, Nelson's input impedance moves around quite a bit, but this discussion makes it a bit unclear to me why that's the case. Thanks for the education...

feel free to do the same with any input stage having clean JFet gates as input

with clean - I mean - no feedback net including gates, which exactly is the case with F4 and similar ones

of course, do not omit gate stoppers, be it one resistor common to both gates , or two separate ones

variations in Rin , with Papamps - most probably which resistor box was nearest in da moment

with clean - I mean - no feedback net including gates, which exactly is the case with F4 and similar ones

of course, do not omit gate stoppers, be it one resistor common to both gates , or two separate ones

variations in Rin , with Papamps - most probably which resistor box was nearest in da moment

Here is a construction tip:

For those diyers like me with no room to store a drill press, a drilling guide made by Big Gator Tools works great in helping me drill holes in heat sinks for tapping. It helps to keep the hole perpendicular to the heat sink, and also the tap perpendicular when starting tapping.

I have found that for large heat sinks when I am not able to clamp the drill guide to the heat sink, I just press the drill guide against the heat sink with one hand and hold drill in the other hand.

The drill guide is not cheap, but it and the hand held drill takes up way less room than a drill press.

I have built three amplifiers using the drill guide to drill and tap the heat sinks, and am now working on my fourth. It works for me.

Drill Guide - Standard V-DrillGuide 1/8"-3/8"

This is the one that I have:

MINI V-DrillGuide

For those diyers like me with no room to store a drill press, a drilling guide made by Big Gator Tools works great in helping me drill holes in heat sinks for tapping. It helps to keep the hole perpendicular to the heat sink, and also the tap perpendicular when starting tapping.

I have found that for large heat sinks when I am not able to clamp the drill guide to the heat sink, I just press the drill guide against the heat sink with one hand and hold drill in the other hand.

The drill guide is not cheap, but it and the hand held drill takes up way less room than a drill press.

I have built three amplifiers using the drill guide to drill and tap the heat sinks, and am now working on my fourth. It works for me.

Drill Guide - Standard V-DrillGuide 1/8"-3/8"

This is the one that I have:

MINI V-DrillGuide

Last edited:

- Home

- Amplifiers

- Pass Labs

- Babelfish M25, SissySIT - general building tips and tricks