RobWells said:I used autocad as it seems to be the industry standard in the UK........

This is one of those cases where they were 1st, got into the hands of people. Then when the next guy asks what to use, the 1st guy only having ever used ACAD recommends it. By the time better products arrive, ACAD is entrenched. The same sort of thing keeps MS Word the dominant word processor.

Amongst the architects locally, VectorWorks (on Macs) is the standard with something like 70% of the market. One of the world famous local architect firms was doing a project with a big firm (350+) from Atlanta and a team was sent to Victoria for a collaboration. Our guys were appalled at how much work is was to try to get something done in AutoCAD, how cludgy & canterkerous it was. And i know a lot of drawers who switched and wouldn't go back (and those that have had to go back & hate it).

Even dice45, our resident ACAD whiz only used it as a programming environment to create his own personal CAD program.

dave

Maybe it's a bit different in the UK - If I was to look through my local jobs section in the paper, most cad jobs would be asking for autocad experience.....

It seems a few UK companies use in house cad systems too..(developed years back and too costly to replace..)

The system we use is only used in the die/cardboard engineering trade(afaik) and not many companies use it - probably about 10 - 30 in the UK (my guess)

Rob

It seems a few UK companies use in house cad systems too..(developed years back and too costly to replace..)

The system we use is only used in the die/cardboard engineering trade(afaik) and not many companies use it - probably about 10 - 30 in the UK (my guess)

Rob

RobWells said:Maybe it's a bit different in the UK - If I was to look through my local jobs section in the paper, most cad jobs would be asking for autocad experience.....

Unfortuneatly this is standard and a huge waste of talent, productivity & capital.

I

The system we use is only used in the die/cardboard engineering trade(afaik) and not many companies use it - probably about 10 - 30 in the UK (my guess)

Hopefully new software tools, standards, and momentum will make small custom systems much more feasible.

I dream of an OS X/Firwire controlled NC Router/Mill...

dave

somehow this moved into a discussion of CAD software?

in that case my 2 cents...

we also use Acad only becasue other software has no support in India just like we use PCs as Macs have little support here. Ihave sued Acad since version 2.

For solid modelling we use Solidworks. reason. My nephew and neice are good at it and they taught me a bit and now I feel comfortable at it. They studied in the UK (Newcastle and Nottingham respectively).

For simple stuff I use Coreldraw (have a friend who is a guru in this) and have used DesignCad and MathCad in the 80s.

cheers...(dont kill me guys another thread that wandered)

in that case my 2 cents...

we also use Acad only becasue other software has no support in India just like we use PCs as Macs have little support here. Ihave sued Acad since version 2.

For solid modelling we use Solidworks. reason. My nephew and neice are good at it and they taught me a bit and now I feel comfortable at it. They studied in the UK (Newcastle and Nottingham respectively).

For simple stuff I use Coreldraw (have a friend who is a guru in this) and have used DesignCad and MathCad in the 80s.

cheers...(dont kill me guys another thread that wandered)

back to the original topic...

Paid a visit to a local hardware store last night. They have rockwool for interior insulation purposes. The stuff is made by St. Gobain. There is a sticker on the pack that it is not considered hazardous according to the European Union list of hazardous materials. So it may be safe to handle and use inside speakers.

It is yellow, pretty dense and feels softer than the rockwool I remember from years ago. More like a cross between cotton wool and the sticky sugar stuff they sell at fairs. Would make pretty good stuffing material, I guess.

Eric

Paid a visit to a local hardware store last night. They have rockwool for interior insulation purposes. The stuff is made by St. Gobain. There is a sticker on the pack that it is not considered hazardous according to the European Union list of hazardous materials. So it may be safe to handle and use inside speakers.

It is yellow, pretty dense and feels softer than the rockwool I remember from years ago. More like a cross between cotton wool and the sticky sugar stuff they sell at fairs. Would make pretty good stuffing material, I guess.

Eric

No, it's not the same. Glass wool actually consists of little glass fibers. For rock wool they put lots of other mineals in the mix.

May main points are:

- This stuff does not seem to be dangerous.

- It is more compact than glass wool and the fibers seem to exhibit a fair amount of friction among themselves so it might be a very good sound absorber which would make it ideal for sealed boxes.

Eric

May main points are:

- This stuff does not seem to be dangerous.

- It is more compact than glass wool and the fibers seem to exhibit a fair amount of friction among themselves so it might be a very good sound absorber which would make it ideal for sealed boxes.

Eric

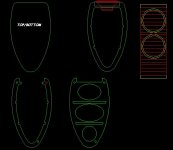

RobWells said:Heres a couple of grabs from my cad at work: [/B]

WOW! What a gorgeous shape!

Can't wait to see real world pics. Is the top going to be flat or have a sensuous shape to match?

dave

Not very exciting really

the bottom left is the sections behind where the speakers will be, the other unfinished layer - the one with speaker drawn on - will be joined across the front behind the baffle. to stiffen the front. The other bit is the brace - the 2 rectangles are where the side to side bracing slides down - it fits in the notches on all layers.

The front view is just to show where the drivers will be with regard to the layers...

I hope this makes some sense...

Cheers

Rob

the bottom left is the sections behind where the speakers will be, the other unfinished layer - the one with speaker drawn on - will be joined across the front behind the baffle. to stiffen the front. The other bit is the brace - the 2 rectangles are where the side to side bracing slides down - it fits in the notches on all layers.

The front view is just to show where the drivers will be with regard to the layers...

I hope this makes some sense...

Cheers

Rob

Dave, I cant believe how fast you posted that! - I was still explaining away on the next post

Thanx to Nick at work for knocking up this 3d image in his lunch break for me - and putting up with me arsing up his settings on his workstation when he's not looking

Cheers

Rob

Thanx to Nick at work for knocking up this 3d image in his lunch break for me - and putting up with me arsing up his settings on his workstation when he's not looking

Cheers

Rob

Attachments

Thanx for the support, Navin / Dave !

Of course you can steal them, Navin....

The mid enclosure will be a long (4-500mm) cylinder going from 6.5 inches to 8.5 inches to 6.5 again - The driver will have no baffle as such, just a chamfer from the edge of the driver backwards.

The tweeter will be above in a small ball type (if I can get it machined right) enclosure, again with no baffle as such..

I've got black american walnut veneer for the main cabs, and am piano laquering (black) the mid/tweets and the top and bottom slice.

The front baffle on the main cab is going top to bottom, and I'm going for mottled black leather to cover this...

I think this covers most bits...

Rob

Of course you can steal them, Navin....

The mid enclosure will be a long (4-500mm) cylinder going from 6.5 inches to 8.5 inches to 6.5 again - The driver will have no baffle as such, just a chamfer from the edge of the driver backwards.

The tweeter will be above in a small ball type (if I can get it machined right) enclosure, again with no baffle as such..

I've got black american walnut veneer for the main cabs, and am piano laquering (black) the mid/tweets and the top and bottom slice.

The front baffle on the main cab is going top to bottom, and I'm going for mottled black leather to cover this...

I think this covers most bits...

Rob

Navin - the easiest way to get that curve is:

draw a line the width of you front baffle(300ish)

offset another line the depth of your speaker(700ish)

shorten the second line to the diameter of the back curve (200ish)

link each end to make a parrallelogram (sp?)

use a "bow" command to drag the sides to your preferred shape.

Thats how I done it!

To measure the volume , Nick suggested drawing a crosshatch of 1cm squares and dropping a "symbol" into each whole square.Then using the system to give a total of the symbols.( any part squares were ignored, allowing a bit of leeway with the size)

counted volume is 115L + all them little bits. As no port is being used I dont need an exact figure as such...Also ignored the holes cut into the bracing....

Rob

draw a line the width of you front baffle(300ish)

offset another line the depth of your speaker(700ish)

shorten the second line to the diameter of the back curve (200ish)

link each end to make a parrallelogram (sp?)

use a "bow" command to drag the sides to your preferred shape.

Thats how I done it!

To measure the volume , Nick suggested drawing a crosshatch of 1cm squares and dropping a "symbol" into each whole square.Then using the system to give a total of the symbols.( any part squares were ignored, allowing a bit of leeway with the size)

counted volume is 115L + all them little bits. As no port is being used I dont need an exact figure as such...Also ignored the holes cut into the bracing....

Rob

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- which type of stuffing?