Mark, great work, 47 pounds... now imagine if you made the entire horn out of foam with glass skins!

Thx!

And no kidding about glassing....

It's blowing my mind, the opportunities

Nice! I've never heard a Synergy horn that big.

Thx Bill,

Size matters, i have to admit

Low mids, upper bass, whatever the term ... really do benefit from lower pattern control.

I'm hoping to take bigger horn experiments ever lower.

This syn has the primary wood flares square cut to allow different XPS foam to 'bolt on' easily.

I could very easily make the primary flare really huge, and then add a second foamboard flare using your great speadsheet for angles.

See pict for how the foamboard flare mount to primary wood flare...

The funny thing to me has been how different the 60x40 and 90x60, with the same size mouth have sounded. Much to sort out still...

now imagine if you made the entire horn out of foam with glass skins!

There is [was?] a major prosound manufacturer making horns and bass bins this way, though IIRC the 'skin' isn't traditional fiberglass layups if I understood the rather cryptic response I got some years ago.

GM

Last edited:

There is [was?] a major prosound manufacturer making horns and bass bins this way, though IIRC the 'skin' isn't traditional fiberglass layups if I understood the rather cryptic response I got some years ago.

GM

Klipsch built the KP-600 systems out of hand laid fiberglass, the enclosures had aluminum reinforcements, and balsa in a few spots on the long panels.

Klipsch KP-600 Eye Candy - Klipsch Pro Audio - The Klipsch Audio Community

Yep, you know, i think we put too much emphasis into polars, because of all of the Harman literature.

Not that i think it's wrong, on the contrary i think it's right.

Right as in a best fit for whatever the room.

It's just....we still have these damn rooms to contend with...and each room has it's own particular best solution.

Sometimes bad directivity might fix/fit the room ????

Which btw, your work and sims on your line array thread continue to blow me away..

I've started to post so many times in the thread.

I've decided you are going to figure out the perfect indoor speaker...

so i just watch and learn, wondering if you will finally compel me in to the world of sims, and maybe another line array ...

I don't think bad directivity would often be the solution. I think its the case that if you have a high ratio of direct to reflected energy and are sitting in the main beam, then imperfections in the polar response don't matter as much.

As to line arrays, I'm learning as much or more than anyone else by doing those simulations. This morning I presented what I think is a compelling case for shading even a floor to ceiling line array, which until now hasn't been considered necessarys. Shading makes a good line array better. If you do frequency dependent shading, you don't need to lose any SPL at the low end.

I think perhaps a perfect line array could be a perfect indoor speaker IFF you had the perfect room for it. The same could be said of a synergy but it would want a different room. Both work well in corners but I can't help thinking large horns need a dedicated room. Well done line arrays at least have a chance of being tolerated in a living or family room... but there will need to be some treatment unless its a really large room.

Last edited:

Update:

Finished detachable flares, and ........a second syn7!

It's the first stereo I've listened to in almost a year, since going down the synergy development hole.

Final weight with flares on, is 52lbs. So foam flares and hardware added only 5 lbs, yay!

Like said, the goal was to be 90x60 conical for the first 2/3's, and as tractrix-like as possible for the last 1/3.

Here's a pict with just the horiz flares attached.

I can move them around from indoors to outdoors, even with the flares attached.

Portability, has been a huge part of the design goal; the flares go on and off pretty easily and quickly. But it's been a pleasant surprise to find I can move them around attached.

That said, their sheer size does make moving them a little awkward, but with each move from place to place, I've been gaining the muscle and logistic memory how to make it easier. So goal met !

Here's a pict from the bottom.

Sound wise....hey, hey, hey...happy camper here

Great imaging, outstanding transients and SPL.

(Lowest SPL box I've built yet lol...single box should be good for >128dB.)

Both running in room.

Surprisingly, the added flares and lower pattern control, appear to have made this the first speaker that almost sounds tonally neutral without any downward tilt in frequency response.

I'd post measurements, but all I have so far is on-axis, tuned to on-axis......which basically always look close to ideal given I use 4-way discrete FIR tuning and just bang out spot on tuning.

So, I'll wait to post polars which no doubt will then show plenty of anomalies.

But since both indoors and outdoors are sounding simply super, ....and portability as well as SPL goals are satisfied, ....polars probably aren't going to matter much to me.

Thx for looking...

Finished detachable flares, and ........a second syn7!

It's the first stereo I've listened to in almost a year, since going down the synergy development hole.

Final weight with flares on, is 52lbs. So foam flares and hardware added only 5 lbs, yay!

Like said, the goal was to be 90x60 conical for the first 2/3's, and as tractrix-like as possible for the last 1/3.

Here's a pict with just the horiz flares attached.

I can move them around from indoors to outdoors, even with the flares attached.

Portability, has been a huge part of the design goal; the flares go on and off pretty easily and quickly. But it's been a pleasant surprise to find I can move them around attached.

That said, their sheer size does make moving them a little awkward, but with each move from place to place, I've been gaining the muscle and logistic memory how to make it easier. So goal met !

Here's a pict from the bottom.

Sound wise....hey, hey, hey...happy camper here

Great imaging, outstanding transients and SPL.

(Lowest SPL box I've built yet lol...single box should be good for >128dB.)

Both running in room.

Surprisingly, the added flares and lower pattern control, appear to have made this the first speaker that almost sounds tonally neutral without any downward tilt in frequency response.

I'd post measurements, but all I have so far is on-axis, tuned to on-axis......which basically always look close to ideal given I use 4-way discrete FIR tuning and just bang out spot on tuning.

So, I'll wait to post polars which no doubt will then show plenty of anomalies.

But since both indoors and outdoors are sounding simply super, ....and portability as well as SPL goals are satisfied, ....polars probably aren't going to matter much to me.

Thx for looking...

If you start messing with fiberglass, take a look at what can be done with stretched fabric over a frame. The entire horn could potentially be made by making a box with shelves that one cut the desired shapes in. Then you stretch the fabric over the top and press down with a 1” rod or 3D-printed horn throat shape of choice. The fabric will take the shape of the cuts in the shelves and the pushrod.

Then cover the fabric in epoxy and let it cure. The hardened horn is not rigid enough but holds the desired shape. To increase the rigidity put fiberglass on the inside. To increase damping of an all fiberglass horn one can experiment with constrained layer damping. Looking from the outside we have the epoxy/fabric then fiberglass then fabric with soft polyurethane rubber brushed on it, and the last layer is fiberglass. Hard skin, soft viscoelastic center.

Then cover the fabric in epoxy and let it cure. The hardened horn is not rigid enough but holds the desired shape. To increase the rigidity put fiberglass on the inside. To increase damping of an all fiberglass horn one can experiment with constrained layer damping. Looking from the outside we have the epoxy/fabric then fiberglass then fabric with soft polyurethane rubber brushed on it, and the last layer is fiberglass. Hard skin, soft viscoelastic center.

Last edited:

To support my claim it’s always a good idea to quote Danley..

Hi guys

For what its worth, the every first one of these below was made using burlap to make the “waveguide”.

Perhaps you can use spandex to do the same thing.

Stretch the fabric across a framework, uniformly stretched a bit.

With something round, the size you need, press in the fabric to the depth you need and clamp in position.

Get some thin epoxy resin from the hobby shop and brush on a few coats until the fabric is ridged enough to deal with. Fill in the rear area with “great stuff” or equivalent polyurethane expanding foam.

Be sure to drill a number of big holes on the back side to let the excess out as it expands.

Figure it will take a couple trys until you get the hang of it but then it will be easy once you figure out what you need for your application.

Good luck

Tom Danley

Page not found | Danley Sound Labs, Inc.

Thx GM, ErnieM, tmuikku, & Nissep,

ErnieM, xovers are LR 72 dB/oct @100Hz, LR 96 dB/oct @ 500Hz, and 96 dB/oct @ 6k3Hz.

Tmuikku, glad you like the looks.

Which is really cool cause I almost never care about looks, just sound quality and meeting objectives..

My girlfriend like the looks too...and that kinda blew my mind given how utilitarian the design is...

I'm just lucky to have a beautiful girlfriend who indulges my hobby so graciously....

Nissep, thanks...very down to earth pragmatic approach...

and your second post helped me visualize the process..

ErnieM, xovers are LR 72 dB/oct @100Hz, LR 96 dB/oct @ 500Hz, and 96 dB/oct @ 6k3Hz.

Tmuikku, glad you like the looks.

Which is really cool cause I almost never care about looks, just sound quality and meeting objectives..

My girlfriend like the looks too...and that kinda blew my mind given how utilitarian the design is...

I'm just lucky to have a beautiful girlfriend who indulges my hobby so graciously....

Nissep, thanks...very down to earth pragmatic approach...

and your second post helped me visualize the process..

If you start messing with fiberglass, take a look at what can be done with stretched fabric over a frame. The entire horn could potentially be made by making a box with shelves that one cut the desired shapes in. Then you stretch the fabric over the top and press down with a 1” rod or 3D-printed horn throat shape of choice. The fabric will take the shape of the cuts in the shelves and the pushrod.

Then cover the fabric in epoxy and let it cure. The hardened horn is not rigid enough but holds the desired shape. To increase the rigidity put fiberglass on the inside. To increase damping of an all fiberglass horn one can experiment with constrained layer damping. Looking from the outside we have the epoxy/fabric then fiberglass then fabric with soft polyurethane rubber brushed on it, and the last layer is fiberglass. Hard skin, soft viscoelastic center.

It is best not to use polyester resin on top of an epoxy part, while it will cure and 'look' ok, it will not have full adhesion to the epoxy. On the other hand, if you have a part made from a polyester resin system, it is fine to repair it with an epoxy resin system.

Not sure if that is what you meant, but for others reading along, the polyester shrinks quite a bit when curing and wants to pull away from the epoxy, if you apply polyester over epoxy.

Glass cloth can be utilized with either polyester or epoxy systems, but if you intend to use chopped mat, use one with a compatible binder, made and marketed for an epoxy system.

Sorry but what I meant was great job with your build! Amazing!

Can you please try ALL my ideas so that I don’t have to..

To make it more clear, the middle viscoelastic layer is a rubber. Polyurethane rubber shore 60a for example, Polytek Poly 75-60 Firm Polyurethane Rubber for Concrete Casting & More - mbfg.co.uk

And it’s not something new.

https://www.acoustics.asn.au/conference_proceedings/INTERNOISE2014/papers/p905.pdf

Can you please try ALL my ideas so that I don’t have to..

To make it more clear, the middle viscoelastic layer is a rubber. Polyurethane rubber shore 60a for example, Polytek Poly 75-60 Firm Polyurethane Rubber for Concrete Casting & More - mbfg.co.uk

And it’s not something new.

https://www.acoustics.asn.au/conference_proceedings/INTERNOISE2014/papers/p905.pdf

Thanks Nissep, and diyuser2010,

I'm kinda psyched about learning using epoxy, glass cloth, polyester resin....

Can see it for all kinds of projects. My 2nd biggest hobby to audio is stand-up jetskis, and I've already started repairing certain parts no longer available.

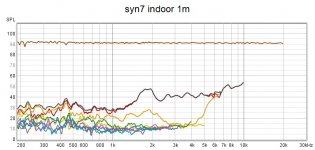

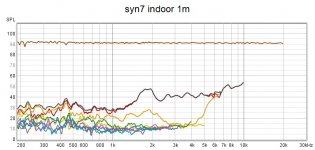

So we have boatloads of rain falling and the only measurements I can take are indoors....aargh...

Here's a quick set of horizontal polars at about 1m. 0,10,20, and 30 degrees.

Green is on-axis with a gentle down-slope house curve in play.

Had to stop at 30 off because of heavy room/object interference beyond that.

Must admit I'm surprised how good these are appearing. Won't know for sure until outdoors, but it looks like the secondary flares have really helped.

Also took a quick distortion test.

SPL is accurate.

I'm kinda psyched about learning using epoxy, glass cloth, polyester resin....

Can see it for all kinds of projects. My 2nd biggest hobby to audio is stand-up jetskis, and I've already started repairing certain parts no longer available.

So we have boatloads of rain falling and the only measurements I can take are indoors....aargh...

Here's a quick set of horizontal polars at about 1m. 0,10,20, and 30 degrees.

Green is on-axis with a gentle down-slope house curve in play.

Had to stop at 30 off because of heavy room/object interference beyond that.

Must admit I'm surprised how good these are appearing. Won't know for sure until outdoors, but it looks like the secondary flares have really helped.

Also took a quick distortion test.

SPL is accurate.

Last edited:

It sure looks like the curved secondary flare does improve the response!Won't know for sure until outdoors, but it looks like the secondary flares have really helped.

Looking forward to seeing the response measured outdoors.

Did you ever check the distortion of the B&C coax using higher crossover point?

Art

It sure looks like the curved secondary flare does improve the response!

Looking forward to seeing the response measured outdoors.

Did you ever check the distortion of the B&C coax using higher crossover point?

Art

Hi Art,

Yep, i'm kinda surprised really how much the secondary flares might be helping. This 90x60 syn without the flares, had the worst polars of any syn attempt I'd tried. Will be glad to get outdoors and see for sure....

I dropped the B&C coax distortion testing after I checked out your excellent distortion test, which kinda led me to "who cares".

I just posted the syn7 distortion cause I know folks like to see distortion. (And it was really low

Oh, that was the bms 4594he..

Awesome! Would you mind raving a bit more on how the stereo pair sounds?  I would also be very interested in an outside comparison with your PM90's

I would also be very interested in an outside comparison with your PM90's  . (when I compared my 1" and 2" synergy horns, the latter sounded way "bigger", but the 1" seemed to have a bigger sweet spot and a slightly better resolution, more "hifi feel". Sound stage and amount of detail are nothing short of amazing, at ANY distance)

. (when I compared my 1" and 2" synergy horns, the latter sounded way "bigger", but the 1" seemed to have a bigger sweet spot and a slightly better resolution, more "hifi feel". Sound stage and amount of detail are nothing short of amazing, at ANY distance)

You have built yourself some creme of the crop speakers! Does anyone know of anything better (PA-wise)?

I really like your idea of "leaving out the box"; saves a lot of room, wood and weight. Smart thinking putting the woofers and their enclosures on top and bottom. You need a straight surface there anyway if you would ever want to put them on top of something other than a stand.

I'm glad to see that positioning of the mid/woofer entries is far easier when you can cross over to the high section at 500 Hz. I have a build coming up with (probably) DE1090TN (B&C) and two12FH500's (Faital) and your solution would be far easier to build. I hope I can get away with this, I'm certainly going to try.

Did you have to insert delays to get all the sections time aligned? Or are we talking microseconds here?

You have built yourself some creme of the crop speakers! Does anyone know of anything better (PA-wise)?

I really like your idea of "leaving out the box"; saves a lot of room, wood and weight. Smart thinking putting the woofers and their enclosures on top and bottom. You need a straight surface there anyway if you would ever want to put them on top of something other than a stand.

I'm glad to see that positioning of the mid/woofer entries is far easier when you can cross over to the high section at 500 Hz. I have a build coming up with (probably) DE1090TN (B&C) and two12FH500's (Faital) and your solution would be far easier to build. I hope I can get away with this, I'm certainly going to try.

Did you have to insert delays to get all the sections time aligned? Or are we talking microseconds here?

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- synergy.....Take #7