Not sure what you mean by length, but one petal fits in 185 x 185 x 170 mm box.How long are these petal segments?

I would say that it doesn't need to be a coax...The ATH A520G2 with the T520-36-ext-1 (1.4" throat extension) with an appropriate 1.4" coax cd like B&C DCX464 would be a good candidate for a 2 way system with an 15".

It doesn't need to be but if one wants the full treble extension and still want to cross as low as possible, it seems to be a good solution.I would say that it doesn't need to be a coax...

If I were to choose an alternative path, I would go for a 1" throat extension with a 1"cd mated with an an 12" woofer crossed higher.

Now, to also make a nice design to make it all look good together

That's often the biggest challengeNow, to also make a nice design to make it all look good together

I've been following this thread for a long time, but my technical knowledge is far too limited to actually contribute anything relevant so far. The last loudspeaker I built was also a 2-way horn (Menhir Klon - not my design, I just used the existing plans) and before that two full range horns (Cyborg's Needle and Jericho Horn).It doesn't need to be but if one wants the full treble extension and still want to cross as low as possible, it seems to be a good solution.

If I were to choose an alternative path, I would go for a 1" throat extension with a 1"cd mated with an an 12" woofer crossed higher.

Now, to also make a nice design to make it all look good together

So finally I want to build a new two-way loudspeaker with an ATH A520G2 (just bought it - thanks Mabat for sharing your work!) and a sealed spherical bass. Again, I have very limited experience in building (or even designing) loudspeakers and can't do any acoustic simulations. But one thing I can bring to this project is the ability "to make it all look good together" (and make assembly plans, engineering drawings if necessary, and parts lists).

Would this community project be something others might be interested in?

Last edited:

You will certainly need acoustic measurements and crossover simulations to carry out a sucessfull loudspeaker design. There's no way around this. So I assume you are willing to learn and do all of this. Fortunately, good and readily available tools are available these days. Anyway, an active setup with DSP is of great help.

- As for the extended throats, please still consider these as somewhat experimental. There are still very few certainties in this regard. It seems to improve things in general, but surprises may happen, even those unpleasant. What's virtually certain is the directivity.

- As for the extended throats, please still consider these as somewhat experimental. There are still very few certainties in this regard. It seems to improve things in general, but surprises may happen, even those unpleasant. What's virtually certain is the directivity.

Last edited:

I have the equipment and the space to make the necessary measurements. I ama a designer by profession as well. However, I am willing to be a part of a community project as much as my time would allow me. I have 10 month old baby!

I will use dsp and active amplification as I am going to use hypex fusion, most probably a 253 (have them in stock). I will bridge the two channels for bass and use the tweeter amp for the horn.

I have in stock a few Acoustic Elegance sbp15 bass drivers with Apollo upgrade. I have to decide if I am going to use a single one or double.

I will use dsp and active amplification as I am going to use hypex fusion, most probably a 253 (have them in stock). I will bridge the two channels for bass and use the tweeter amp for the horn.

I have in stock a few Acoustic Elegance sbp15 bass drivers with Apollo upgrade. I have to decide if I am going to use a single one or double.

Thanks for your great work, Marcel! I managed to run ath on tritoniaX and even akabak, VACS looks great, I think. I'm currently considering cloning an old monitor design that is using an MRH-320 which is hard to find, currently, but the community created a 3d model for me to use.

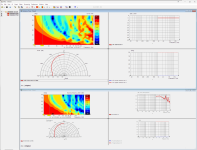

In Akabaka and VACS (if I actually know now what I'm doing which I'm not so sure about), that one looks like in my attachment.

To my inexperienced eye, it looks worse. So I was starting to mess with the tritonia cfg to come closer to the mrh320 cutout measurements like so:

Throat.Diameter = 36 ; [mm]

Throat.Angle = 0 ; [deg]

Throat.Profile = 1

Length = 40 ; [mm]

Coverage.Angle = 38 - 20*cos(2*p)^5 - 25*sin(p)^12

Term.s = 0.7 + 0.2*cos(p)^2

Term.n = 3.7

Term.q = 0.995

Slot.Length = 20*sin(p)^4

Morph.TargetShape = 1

Morph.FixedPart = 0.0

Morph.Rate = 3

Morph.CornerRadius = 4

Morph.TargetHeight = 165

Morph.TargetWidth = 260

which works but I don't understand that this is better than mrh320.

If I increase the length, I also get too wide and too high which I guess is about the s n and q terms.

Practically, what are some key targets in changing these and how would you prioritise reaching them?

thanks

In Akabaka and VACS (if I actually know now what I'm doing which I'm not so sure about), that one looks like in my attachment.

To my inexperienced eye, it looks worse. So I was starting to mess with the tritonia cfg to come closer to the mrh320 cutout measurements like so:

Throat.Diameter = 36 ; [mm]

Throat.Angle = 0 ; [deg]

Throat.Profile = 1

Length = 40 ; [mm]

Coverage.Angle = 38 - 20*cos(2*p)^5 - 25*sin(p)^12

Term.s = 0.7 + 0.2*cos(p)^2

Term.n = 3.7

Term.q = 0.995

Slot.Length = 20*sin(p)^4

Morph.TargetShape = 1

Morph.FixedPart = 0.0

Morph.Rate = 3

Morph.CornerRadius = 4

Morph.TargetHeight = 165

Morph.TargetWidth = 260

which works but I don't understand that this is better than mrh320.

If I increase the length, I also get too wide and too high which I guess is about the s n and q terms.

Practically, what are some key targets in changing these and how would you prioritise reaching them?

thanks

Attachments

As Mabat and Kodomo recommended, using an active system with DSP is likely the most effective approach. Acoustic measurements should not be an insurmountable challenge.

The plan is to finalize together a preliminary design and components list, from which I will create a 3D mockup (e.g., using ATH A520G2 + AE SBP15 in a spherical enclosure of specified volume). This will be followed by several design iterations based on acoustic analysis, leading to further revisions.

Once we agree on the design, we can discuss assembly details, including materials (here's an interesting thread on horn construction). I will then build a prototype and share the outcomes, including failures, successes, and measurements. Ultimately, I aim to provide assembly plans, engineering drawings, DSP settings and a parts list to simplify replication.

Again, I can't do any acoustic analysis, so I'll have to rely on the expertise of others.

The plan is to finalize together a preliminary design and components list, from which I will create a 3D mockup (e.g., using ATH A520G2 + AE SBP15 in a spherical enclosure of specified volume). This will be followed by several design iterations based on acoustic analysis, leading to further revisions.

Once we agree on the design, we can discuss assembly details, including materials (here's an interesting thread on horn construction). I will then build a prototype and share the outcomes, including failures, successes, and measurements. Ultimately, I aim to provide assembly plans, engineering drawings, DSP settings and a parts list to simplify replication.

Again, I can't do any acoustic analysis, so I'll have to rely on the expertise of others.

PS: I just now discovered k, bringing me close enough to the target height and width:

Throat.Diameter = 25.4 ; [mm]

Throat.Angle = 0 ; [deg]

Throat.Profile = 1

Length = 140 ; [mm]

Coverage.Angle = 38 - 20*cos(2*p)^5 - 25*sin(p)^12

Term.s = 0.7 + 0.2*cos(p)^2

Term.n = 3.7

Term.q = 0.995

OS.k = 10

Slot.Length = 20*sin(p)^4

Morph.TargetShape = 1

Morph.FixedPart = 0.0

Morph.Rate = 3

Morph.CornerRadius = 4

Morph.TargetHeight = 165

Morph.TargetWidth = 260

looking at the polars, is this better than mrh320?

Throat.Diameter = 25.4 ; [mm]

Throat.Angle = 0 ; [deg]

Throat.Profile = 1

Length = 140 ; [mm]

Coverage.Angle = 38 - 20*cos(2*p)^5 - 25*sin(p)^12

Term.s = 0.7 + 0.2*cos(p)^2

Term.n = 3.7

Term.q = 0.995

OS.k = 10

Slot.Length = 20*sin(p)^4

Morph.TargetShape = 1

Morph.FixedPart = 0.0

Morph.Rate = 3

Morph.CornerRadius = 4

Morph.TargetHeight = 165

Morph.TargetWidth = 260

looking at the polars, is this better than mrh320?

Attachments

I also have 15” AE dipoles at hand and I like large baffles for bass. I may go for something like a Klangfilm OBAs Mabat and Kodomo recommended, using an active system with DSP is likely the most effective approach. Acoustic measurements should not be an insurmountable challenge.

The plan is to finalize together a preliminary design and components list, from which I will create a 3D mockup (e.g., using ATH A520G2 + AE SBP15 in a spherical enclosure of specified volume). This will be followed by several design iterations based on acoustic analysis, leading to further revisions.

Once we agree on the design, we can discuss assembly details, including materials (here's an interesting thread on horn construction). I will then build a prototype and share the outcomes, including failures, successes, and measurements. Ultimately, I aim to provide assembly plans, engineering drawings, DSP settings and a parts list to simplify replication.

Again, I can't do any acoustic analysis, so I'll have to rely on the expertise of others.

I also have 15” AE dipoles at hand and I like large baffles for bass. I may go for something like a Klangfilm OB

I appreciate the concept of a system like the Klangfilm OB, but wouldn't that complicate the placement of the speaker in a room? Also, wouldn't that require using two 15" drivers and make positioning the horn relative to the drivers more challenging?

- Home

- Loudspeakers

- Multi-Way

- Acoustic Horn Design – The Easy Way (Ath4)