Why round?

The Monkey Coffin speaker should be easy enough to make for newcomers (or myself). Routing an ellipse is not something I would consider easy enough. A circle is.

Just to be sure I got this right: a waveguide with approx. 4" diameter should work out okay for a 2.5 kHz xover?

Last edited:

Well, on paper so far, it looks pretty doable with a 4". But the exact mid you use and crossover slopes will have an impact on that.

As far as routing, it is actually quite easy to do this once you understand how to route a template. If my novice wood working can pull it off anyone can.

As far as routing, it is actually quite easy to do this once you understand how to route a template. If my novice wood working can pull it off anyone can.

Mbrennwa,

Check this method. All my irregular cutouts come out perfectly with this method and its really affordable! I blue tape all of my cuts, using enough to level the router, on the actual cut, dont just blue tape the cut, but the entire area. Keeps blowouts from happening, especially with the 1/32 raw veeners I use.

Tip: How To Flush Mount Irregular Shape Driver -

Techtalk Speaker Building, Audio, Video Discussion Forum

Cheers,

Greg

Check this method. All my irregular cutouts come out perfectly with this method and its really affordable! I blue tape all of my cuts, using enough to level the router, on the actual cut, dont just blue tape the cut, but the entire area. Keeps blowouts from happening, especially with the 1/32 raw veeners I use.

Tip: How To Flush Mount Irregular Shape Driver -

Techtalk Speaker Building, Audio, Video Discussion Forum

Cheers,

Greg

Oh, that does seem easy. I just need a perfectly round base for my router, which should not be too difficult to make.

That's how I do it. Here is another: Tutorial: How to flush-mount irregular shaped speakers : diyaudio

I have also designed the template for a few of these waveguides if you printed them, then you just need the two router bushings to make the inside and outside cuts.

I have also designed the template for a few of these waveguides if you printed them, then you just need the two router bushings to make the inside and outside cuts.

Last edited:

Placekeeper post as I catch up

Re: post 77 Gaga & post 78 Augerpro

positioning of waveguide wall relative to surround roll and dome

Re: post 77 Gaga & post 78 Augerpro

positioning of waveguide wall relative to surround roll and dome

Oh, that does seem easy. I just need a perfectly round base for my router, which should not be too difficult to make.

Ha! You can make that as well with your router.

An externally hosted image should be here but it was not working when we last tested it.

Since you're building and measuring so many waveguides, have you considered doing one with multiple geometries?

I've thought about it but don't even know where to start with those. And I'm not sure it it would transfer well to domes, I suspect the LSR305 is just using the waveguide for marketing of the "JBL family" than actual performance. OTOH, I do actually have a pair, so I suppose I should measure them...

If you can provide the width, height and depth, I can make you one and send it to you.

I would also need to know the diameter of the throat.

I would also need to know the diameter of the throat.

Several issues to be considered in the throat:

Another use for a felt ring similar to that referred to in post #220;

Occlusion of the outer ring of the ring radiator (diameter of throat)

Entry angle of the throat;

Now, consider the addition of a felt ring inside that portion of the throat which occludes the outer ring...the felt to be recessed into the throat...think of it as the inner surface of a thicker shim.

there is some radiation of energy across the outer ring which diminishes with increasing diameter. My speculation is that there is a "sweet spot" for throat angle/diameter/occlusion.

Another use for a felt ring similar to that referred to in post #220;

Occlusion of the outer ring of the ring radiator (diameter of throat)

Entry angle of the throat;

Now, consider the addition of a felt ring inside that portion of the throat which occludes the outer ring...the felt to be recessed into the throat...think of it as the inner surface of a thicker shim.

there is some radiation of energy across the outer ring which diminishes with increasing diameter. My speculation is that there is a "sweet spot" for throat angle/diameter/occlusion.

Surprisingly my experiements with occluding the surround have been quite poor. Although no felt was used. I'm a bit hesitant to try something that will be difficult for others to consistently copy since the entire intent of this project is make the designs openly available. But maybe I'm wrong and and people would like that feature investigated?

I only have throat shims for the SB26, so I measured with those today on the 4" waveguide. I measured the aluminum and fabric dome, no phase shield.

Seems like an improvement so I'll have to look into this more. Prior to this I didn't see this improvement, I wonder if it is because the smaller throat of the 4" (forgot to print the new 5" and 8" if you remember) allows this to move the performance forward, while prior throats were large enough to cause problems that over-rode the effects of the shim. At this point I'm very happy with the performance of many of these waveguides, some obviously need improvement. Since I doubt the printer will keep printing random variations, and it would really have to be luck to get some better results, at least for the sB26 and SB21, I think I probably need learn ABEC3 now.

Seems like an improvement so I'll have to look into this more. Prior to this I didn't see this improvement, I wonder if it is because the smaller throat of the 4" (forgot to print the new 5" and 8" if you remember) allows this to move the performance forward, while prior throats were large enough to cause problems that over-rode the effects of the shim. At this point I'm very happy with the performance of many of these waveguides, some obviously need improvement. Since I doubt the printer will keep printing random variations, and it would really have to be luck to get some better results, at least for the sB26 and SB21, I think I probably need learn ABEC3 now.

Brandon,

You have definitely mentioned a good seal between the WG and the driver, however, I wonder if the tweeter should be enclosed within the box to completely rule out the woofer pressurizing the tweeters dome and at the same time unloading the woofer.

I apologize in advance if this has already been discussed.

Cheers,

Greg

You have definitely mentioned a good seal between the WG and the driver, however, I wonder if the tweeter should be enclosed within the box to completely rule out the woofer pressurizing the tweeters dome and at the same time unloading the woofer.

I apologize in advance if this has already been discussed.

Cheers,

Greg

Hi Brandon,

With respect to the shims (or the 'step' at the WG throat as discussed earlier in this thread): Nice to see an improvement here with the 4''-WG.

From my experience, the possible improvement by a shim/step largely depends on the geometry of the respective dome applied to the WG. I'm working on the impact of the dome shape (both, concave or convex) on the directivity of tweeters and the possible implication for use with a WG over in the German DIY Hifi Forum here.

However, as you have to register to see the images there, I briefly summarize here:

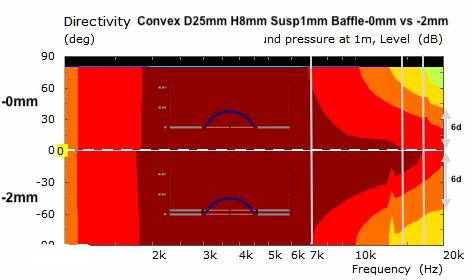

This one shows the directivity (here SPL from 0° to 90° and for sake of better clarity at 0°, 30° and 60°) of a dome tweeter with a 1''-diameter, a 1mm suspension and a dome height of 8mm in a infinite baffle - and the impact of 'Shims' or 'Steps' increasing from 0mm to -8mm on directivity.

You can clearly see the improvement with respect to a more consistent directivity at high frequencies around the -2mm step.

Directivity at high frequencies of a tweeter-WG-combination is largely determiend by the WG-throat...

What happens here? If we look at the directivity of a flat 1''-membrane we see increasing dips with increasing angles due to different travel times of sound from the outer edges of the membrane.

and

With a 2mm 'Shim' or 'Step'...

...dips under increasing angles are less deep or severe, because the step causes a 'virtual' decrease of the membrane diameter. Of course, increasing step-height introduces new issues by constituting 'secondary sound sources' (see first image with steps >2mm).

Basically same happens with dome membranes:

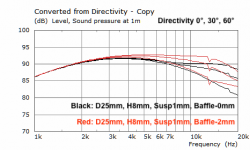

Comparison of SPL at 0°, 30° and 60° of a 1''-dome, dome height 8mm, 1mm suspension mounted in a flat front of with -2mm 'step' / 'shim':

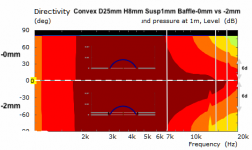

Comparison of directivity:

Finally the impact of the 'Step' or 'Shim' on the SB26ADC mounted to an elliptical WG (contour derived from one of the 'Brandon WGs shown before):

Though the impact of the steps is quite obvious, arrows show some changes of interest. I think these dips were measured and discussed by Brandon before.

Of course, if you go for elliptical shapes and more complicted throat-designs (like the newer JBL) you'll need ABEC3. However, I'll be happy to support here as far as my (rather limited) time allows me to do.

Coming back to dome shapes and shims: From my point of view, the highest potential of developing and printing own WGs lies in the adaption of the WG throat to a specific tweeter... Dome diameter, dome shape, dome height and width of suspension come in here.

Seems like an improvement so I'll have to look into this more. Prior to this I didn't see this improvement, I wonder if it is because the smaller throat of the 4" (forgot to print the new 5" and 8" if you remember) allows this to move the performance forward, while prior throats were large enough to cause problems that over-rode the effects of the shim.

With respect to the shims (or the 'step' at the WG throat as discussed earlier in this thread): Nice to see an improvement here with the 4''-WG.

From my experience, the possible improvement by a shim/step largely depends on the geometry of the respective dome applied to the WG. I'm working on the impact of the dome shape (both, concave or convex) on the directivity of tweeters and the possible implication for use with a WG over in the German DIY Hifi Forum here.

However, as you have to register to see the images there, I briefly summarize here:

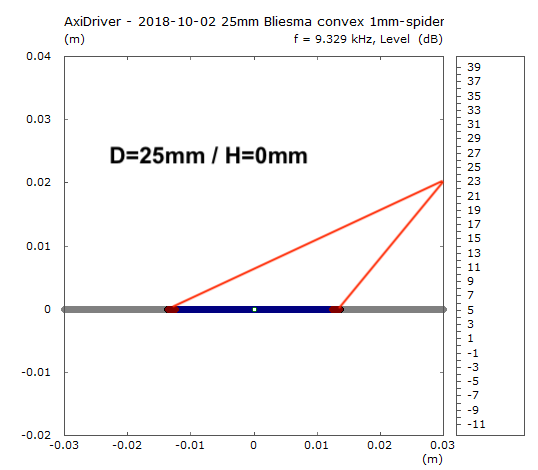

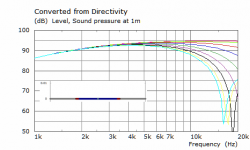

This one shows the directivity (here SPL from 0° to 90° and for sake of better clarity at 0°, 30° and 60°) of a dome tweeter with a 1''-diameter, a 1mm suspension and a dome height of 8mm in a infinite baffle - and the impact of 'Shims' or 'Steps' increasing from 0mm to -8mm on directivity.

You can clearly see the improvement with respect to a more consistent directivity at high frequencies around the -2mm step.

Directivity at high frequencies of a tweeter-WG-combination is largely determiend by the WG-throat...

What happens here? If we look at the directivity of a flat 1''-membrane we see increasing dips with increasing angles due to different travel times of sound from the outer edges of the membrane.

and

With a 2mm 'Shim' or 'Step'...

...dips under increasing angles are less deep or severe, because the step causes a 'virtual' decrease of the membrane diameter. Of course, increasing step-height introduces new issues by constituting 'secondary sound sources' (see first image with steps >2mm).

Basically same happens with dome membranes:

Comparison of SPL at 0°, 30° and 60° of a 1''-dome, dome height 8mm, 1mm suspension mounted in a flat front of with -2mm 'step' / 'shim':

Comparison of directivity:

Finally the impact of the 'Step' or 'Shim' on the SB26ADC mounted to an elliptical WG (contour derived from one of the 'Brandon WGs shown before):

Though the impact of the steps is quite obvious, arrows show some changes of interest. I think these dips were measured and discussed by Brandon before.

I fully agree, very nice results already!At this point I'm very happy with the performance of many of these waveguides,...

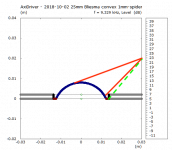

Well, not necessarily ABEC3. All images - except the last one - shown in this post have been derived from AxiDriver, which is much easier to handle than ABEC3.and it would really have to be luck to get some better results, at least for the sB26 and SB21, I think I probably need learn ABEC3 now.

Of course, if you go for elliptical shapes and more complicted throat-designs (like the newer JBL) you'll need ABEC3. However, I'll be happy to support here as far as my (rather limited) time allows me to do.

Coming back to dome shapes and shims: From my point of view, the highest potential of developing and printing own WGs lies in the adaption of the WG throat to a specific tweeter... Dome diameter, dome shape, dome height and width of suspension come in here.

Attachments

-

2018-10-20 Bliesma 25mm susp1mm convex-H8mm front 0-8mm 1 small.png208.2 KB · Views: 1,319

2018-10-20 Bliesma 25mm susp1mm convex-H8mm front 0-8mm 1 small.png208.2 KB · Views: 1,319 -

2018-10-02 Bliesma D-25mm convex Susp-1mm H0mm Membrane 2.png27.3 KB · Views: 1,284

2018-10-02 Bliesma D-25mm convex Susp-1mm H0mm Membrane 2.png27.3 KB · Views: 1,284 -

2018-10-21 Bliesma D-25mm Susp-1mm H0mm Membrane-0mm 0-90Gr 1.png15.1 KB · Views: 1,275

2018-10-21 Bliesma D-25mm Susp-1mm H0mm Membrane-0mm 0-90Gr 1.png15.1 KB · Views: 1,275 -

2018-10-21 Bliesma D25mm H8mm Susp1mm Baffle-0mm vs-2mm 63-93dB direct 1 Kopie.png28.1 KB · Views: 1,300

2018-10-21 Bliesma D25mm H8mm Susp1mm Baffle-0mm vs-2mm 63-93dB direct 1 Kopie.png28.1 KB · Views: 1,300 -

2018-10-21 Bliesma D-25mm Susp-1mm H0mm Membrane-2mm 0-90Gr 1.png22.9 KB · Views: 1,276

2018-10-21 Bliesma D-25mm Susp-1mm H0mm Membrane-2mm 0-90Gr 1.png22.9 KB · Views: 1,276 -

2018-10-21 Bliesma D-25mm Susp-1mm H8mm Membrane-0mm vs -2mm 0-30-60Gr 1.png25.9 KB · Views: 1,278

2018-10-21 Bliesma D-25mm Susp-1mm H8mm Membrane-0mm vs -2mm 0-30-60Gr 1.png25.9 KB · Views: 1,278 -

2018-10-20 Bliesma d25mm susp-1mm convex-H8mm membr-2mm image 1.png25.9 KB · Views: 1,288

2018-10-20 Bliesma d25mm susp-1mm convex-H8mm membr-2mm image 1.png25.9 KB · Views: 1,288 -

2018-05-01 Elliptical WG contour V2 spline SB26ADC neu Step 0-5mm 1.jpg163 KB · Views: 1,341

2018-05-01 Elliptical WG contour V2 spline SB26ADC neu Step 0-5mm 1.jpg163 KB · Views: 1,341

Last edited:

Brandon,

You have definitely mentioned a good seal between the WG and the driver, however, I wonder if the tweeter should be enclosed within the box to completely rule out the woofer pressurizing the tweeters dome and at the same time unloading the woofer.

I apologize in advance if this has already been discussed.

Cheers,

Greg

Possibly. I would look at the tweeter itself and see how well the faceplate is sealed to the motor. Some are completely glued, some have a gasket, and some, like the SB26, don't have anything and I would definitely do something with it. You could build a chamber, or use something like bluetac or maybe plumbers putty to seal it.

Anything new going on with the 4" waveguides?

Here's sneak pics on my project with your 6" waveguide for SB26ADC, active 3-way monitor with DSP functionality. Genelec said they have the smallest 3-way speaker with 8331, I made it smaller. 🙂

Aim is to get same freq. response, but lower max SPL.

Here's sneak pics on my project with your 6" waveguide for SB26ADC, active 3-way monitor with DSP functionality. Genelec said they have the smallest 3-way speaker with 8331, I made it smaller. 🙂

Aim is to get same freq. response, but lower max SPL.

Attachments

Nothing yet, I'm trying to determine if I can even improve on the performance. I think the only way forward for that is ABEC modeling. What kind of mid are you using?

- Home

- Loudspeakers

- Multi-Way

- Open source Waveguides for CNC & 3D printing!