Does anyone know where in europe to buy flat pack classic golden ratio or similar small enclosure for 7cm MA drivers (alpair 7p specifically)?

Is getting them custom CNCed the typical way of doing it? Seems expensive.

Is getting them custom CNCed the typical way of doing it? Seems expensive.

Last edited:

I'm afraid we don't stock them, I think you might struggle TBH. I don't think anyone stocked them and the Alpair 7 has been discontinued for a while so it seems unlikely now.

No worries, I would really prefer something fully diy anyway. Thinking of concrete as an alternative, will be tricky but there is not much to lose and plenty of room for failures since it so inexpensive.

Is getting them custom CNCed the typical way of doing it? Seems expensive.

As CNC becomes nore common and machines continue to fall in price, CNCed speakers will become more common.

I have talked with Stefan about the possibility of doing some of the planet10-hifi boxes as flat-paks, but he has yet to have anyone poke him hard enuff.

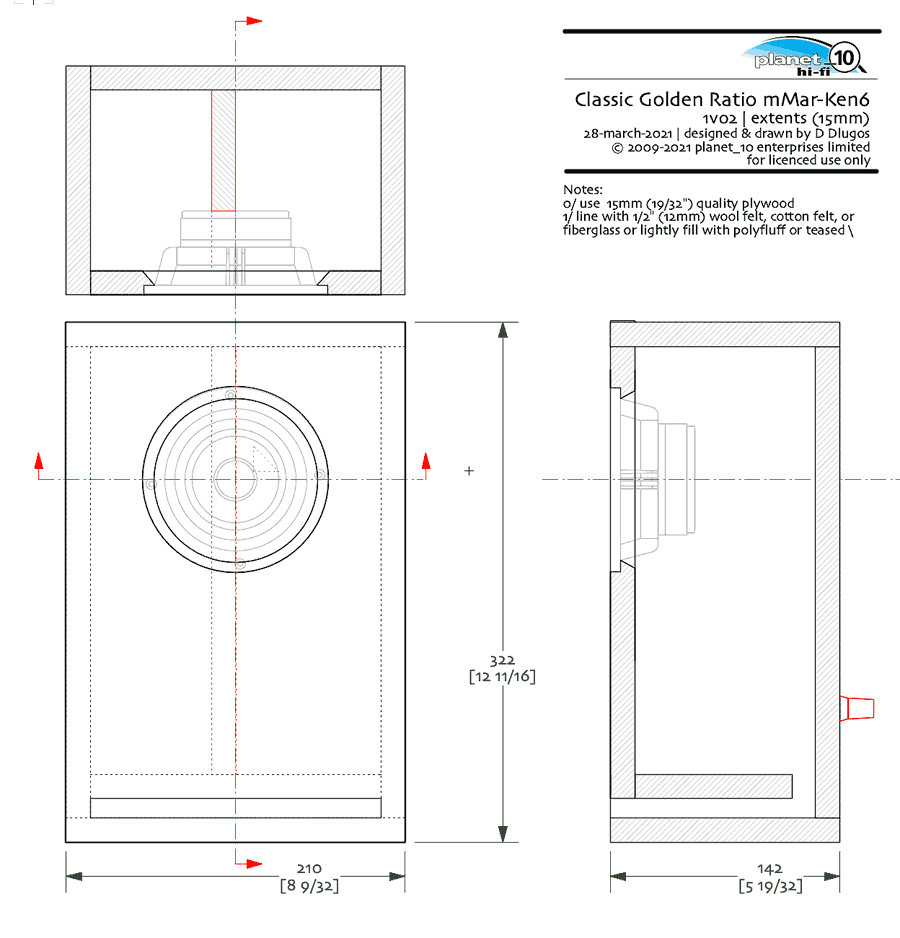

A CGR is certainly doable. We shipped a few of them.

dave

Was a 7p tuned version of any of the desktop/small size enclosures every designed? Cant find any available publicly, but maybe they are part of a subscription?

laserscrape,

Here you go with a stand-mount design for the Alpair 7P:

https://www.diyaudio.com/forums/full-range/356380-alpair-7p-enclosure-2.html#post6252917

Planet10 might have paid plan-sets.

Do you already have the drivers?

Here you go with a stand-mount design for the Alpair 7P:

https://www.diyaudio.com/forums/full-range/356380-alpair-7p-enclosure-2.html#post6252917

Planet10 might have paid plan-sets.

Do you already have the drivers?

Thanks and yes, had them for a while but never built a proper enclosure.

I like the wide CGR designs, the form factor really suits, but a simple round port design like this would be so much easier to cast.

I like the wide CGR designs, the form factor really suits, but a simple round port design like this would be so much easier to cast.

Planet10 might have paid plan-sets.

A7p can be fitted into the milliSize enclosure. It is the smallest. You will not find any P10-hifi plans without high ratio slot vents.

A7p is about the same size bezel as the FE127eN in these.

dave

Is getting them custom CNCed the typical way of doing it? Seems expensive.

I don't feel like anyone answered this part: No! People usually make these by hand - using power tools, sure, but not CNC. It really only takes a wood router and a saw, and you can avoid needing a saw if you pay the shop that sells you the plywood to cut the panels to size.

I don't feel like anyone answered this part: No! People usually make these by hand - using power tools, sure, but not CNC. It really only takes a wood router and a saw, and you can avoid needing a saw if you pay the shop that sells you the plywood to cut the panels to size.

While certainly inefficient to use only for sizing rectangular parts, for companies supplying a range of flat pack kits and / or assembled enclosures for a range of makes/models - particularly enclosures such as the Frugelhorn family - or curved designs skinned over a skeletal frame, or stacked laminations such as WeSaySo’s line arrays, to name just a few, CNC machining makes a lot of sense.

As for relying on the shop that sells you the plywood to cut the panels to required sizes, unless you have good reason to trust their accuracy, I’d be prepared to resize some of them.

for companies...CNC machining makes a lot of sense.

Oh, certainly. I just meant to answer the question with regard to the expense of buying custom CNC panels i.e. nobody does that if they don't have to.

Alpair 11MS Gen2

Hi guys!

I have recently ordered a pair of Alpair 11MS drivers from KJF Audio and I was surprised when I received a Gen 2 version. I was not aware that there is a Gen 2 version of these drivers and I can't find any info on them. Does anyone know anything about these new drivers? Can they be used in enclosures designed for Generation 1 drivers (Nostromo)?

Hi guys!

I have recently ordered a pair of Alpair 11MS drivers from KJF Audio and I was surprised when I received a Gen 2 version. I was not aware that there is a Gen 2 version of these drivers and I can't find any info on them. Does anyone know anything about these new drivers? Can they be used in enclosures designed for Generation 1 drivers (Nostromo)?

Attachments

As far as I recall, there is from a user's perspective essentially no such thing, label and to a point language barriers notwithstanding. If memory serves some minor changes were made to the composition of the surround to reduce the number that failed to meet tolerance, but this did not significantly affect the baseline frequency, impedance responses, or cause the parameters to drift away from the production QA / QC tolerance vis-a-vis advertised spec. under the given test conditions. It was just a change made for manufacturing reasons to reduce wastage and while it's certainly honest to note it, it doesn't really affect buyers per se. I'll double-check, but as far as I know, that's the state of play.

but this did not significantly affect the baseline frequency, impedance responses, or cause the parameters to drift away from the production QA / QC tolerance vis-a-vis advertised spec. it doesn't really affect buyers per se.

Probably thats why the officially published spec sheet is the same at mark audio website.

...from a user's perspective essentially no such thing...

Way more changes were made during the lifespan of the A7.3 and it did not become an A7.5

It is worth noting that the difference bewteen A7.1 and A7.2 was the super gasket, those 2 only got those designations after the A7.3 came out.

So one has to note that generation designations are somewhat fluid.

dave

I read a comment that their might be a 10'' FR driver from MA in the works... anyone know if there is any truth that?

IIRC there was some interest in designing one, or at least a unit with a ~10in basket diameter. However, as far as I know there isn't such a driver imminent. I'll see if I can find out though.

- Home

- Loudspeakers

- Full Range

- New Markaudio Drivers