Thanks Veleric for your honest opinion. I am trying to avoid experimenting with endless panel material and exciter combinations myself, but will probably end up doing that eventually (I suspect).Take this, like everything you read about panel speakers, with a big grain of salt, and believe nothing until you've tried it and verified it yourself!

I think there are already more than enough tidbits in this thread alone to build great sounding panels - thanks to you guys who have walked the road and freely share your knowledge and experiences. Looking forward to starting my own journey with DMLs soon.

Hey everyone, I've been back and forth between several designs for my .4 atmos DML panels, and i've settled on 2x3', 1/8" birch/w spruce core plywood panels. I've already cut and rounded the wood and begun on the mounts.

My question is, since these will be ceiling mounted (horizontally) will the single exciter alone (Dayton Audio DAEX30HESF-4) be strong enough to support the panel? I have epoxy to supplement the 3M glue, but im concerned it will also not be leveled.

I've come up with a design that could support the panel, but i've read its a big no-no to put any support on that side of the panel, only the edges.

Is there another way of supporting the panel other then what my example shows?

I'm currently considering fishing line, but I also have some elastic wire, strung out only to support and level it. I'd really prefer not to do a frame.

I hope someone has a good idea!

My question is, since these will be ceiling mounted (horizontally) will the single exciter alone (Dayton Audio DAEX30HESF-4) be strong enough to support the panel? I have epoxy to supplement the 3M glue, but im concerned it will also not be leveled.

I've come up with a design that could support the panel, but i've read its a big no-no to put any support on that side of the panel, only the edges.

Is there another way of supporting the panel other then what my example shows?

I'm currently considering fishing line, but I also have some elastic wire, strung out only to support and level it. I'd really prefer not to do a frame.

I hope someone has a good idea!

Attachments

correction, the panels are 1/5" thick birch/spruce ply, so fairly rigid but was not completely flat from the store.Hey everyone, I've been back and forth between several designs for my .4 atmos DML panels, and i've settled on 2x3', 1/8" birch/w spruce core plywood panels. I've already cut and rounded the wood and begun on the mounts.

My question is, since these will be ceiling mounted (horizontally) will the single exciter alone (Dayton Audio DAEX30HESF-4) be strong enough to support the panel? I have epoxy to supplement the 3M glue, but im concerned it will also not be leveled.

I've come up with a design that could support the panel, but i've read its a big no-no to put any support on that side of the panel, only the edges.

Is there another way of supporting the panel other then what my example shows?

I'm currently considering fishing line, but I also have some elastic wire, strung out only to support and level it. I'd really prefer not to do a frame.

I hope someone has a good idea!

H

I've come up with a design that could support the panel...

I like your choice of panel, but I think your design for the supports is going to be difficult to make work.

You definitely don't want the weight of the panel hanging only by the exciter, as the weight will pull the voice coil away from the neutral position, and if the exciter is not dead center and hence balanced, the panel wouldn't even sit flat. So for sure you need some other way to support the panel.

What's the reason you don't want a frame? Is it just the appearance of the seemingly "floating" panel what you want to preserve?

I have a strong preference for frames, for several reasons. Mainly, when I've tested panels that are largely unsupported around the edges, the base frequency response has generally been been compromised, both in sound power and especially in smoothness of frequency response. And for a wood panel, a frame will help a bit to reduce warping of the panel with changes in humidity.

If the idea is to preserve the floating appearance, my suggestion would be to try this: Build a "frame" but make it several inches smaller in both length and width than the panels, say 18" x 30" compared to your 24" x 36" panel.

Attach foam strips to the face of the frame, and then attach the back surface of the panel to the foam strips. For foam, you could use this:

McMaster-Carr

I like the 3/4" wide x 3/8" thick foam.

It has adhesive already on one side so you can stick it firmly to the frame. Then use double sided tape or spray adhesive to attach the panel to the foam.

Now, to be clear, I have never tried a version where the panel extends more than a little beyond the edges of the frame, so I can't say for certain how well it will work. But my suspicion is that it will perform better than a substantially free panel.

For attaching the exciter, probably you could simply use the supplied tape alone, or mount it on a spline spanning the frame. But since the panel is laying horizontal I suspect the need for a spline is much reduced.

One thing I like about NOT using a spline is that if the panel warps (and wood surely will), it won't push or pull on the voice coil, as the exciter will just float on the panel where ever it goes.

Then attach the frame to the ceiling however you want, maybe short vertical fishing line would be good for that, for example.

But whatever you plan, I highly suggest making and testing a prototype (or several!) before committing fully to a design.

Eric

I like your choice of panel, but I think your design for the supports is going to be difficult to make work.

You definitely don't want the weight of the panel hanging only by the exciter, as the weight will pull the voice coil away from the neutral position, and if the exciter is not dead center and hence balanced, the panel wouldn't even sit flat. So for sure you need some other way to support the panel.

What's the reason you don't want a frame? Is it just the appearance of the seemingly "floating" panel what you want to preserve?

I have a strong preference for frames, for several reasons. Mainly, when I've tested panels that are largely unsupported around the edges, the base frequency response has generally been been compromised, both in sound power and especially in smoothness of frequency response. And for a wood panel, a frame will help a bit to reduce warping of the panel with changes in humidity.

If the idea is to preserve the floating appearance, my suggestion would be to try this: Build a "frame" but make it several inches smaller in both length and width than the panels, say 18" x 30" compared to your 24" x 36" panel.

Attach foam strips to the face of the frame, and then attach the back surface of the panel to the foam strips. For foam, you could use this:

McMaster-Carr

I like the 3/4" wide x 3/8" thick foam.

It has adhesive already on one side so you can stick it firmly to the frame. Then use double sided tape or spray adhesive to attach the panel to the foam.

Now, to be clear, I have never tried a version where the panel extends more than a little beyond the edges of the frame, so I can't say for certain how well it will work. But my suspicion is that it will perform better than a substantially free panel.

For attaching the exciter, probably you could simply use the supplied tape alone, or mount it on a spline spanning the frame. But since the panel is laying horizontal I suspect the need for a spline is much reduced.

One thing I like about NOT using a spline is that if the panel warps (and wood surely will), it won't push or pull on the voice coil, as the exciter will just float on the panel where ever it goes.

Then attach the frame to the ceiling however you want, maybe short vertical fishing line would be good for that, for example.

But whatever you plan, I highly suggest making and testing a prototype (or several!) before committing fully to a design.

Eric

Thank you for your input Eric, I really appreciate it.

You are right about the idea that these should appear like floating panels as much as possible, but I recognize that they do need support, and the frame suggestion you describe sound like an excellent idea.

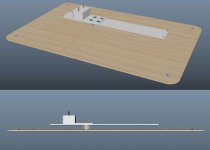

I've gone ahead and bought 16 meters foam tube which i've modeled in with a frame design as you described.

I decided on a D-tube as you can see on the picture, as I imagine this will give a better suspension.

I 3D modeled in the woodframe for the tube using the same 1/5" wood as I used or the panels. This helps me keep a low profile and I have leftover from the panels I can use, hopefully it's strong enough.

It is placed 2" in from the edge.

Then in using a piece of MDF i also have enough of from scraps to mount the frame to the ceiling mount (which I already made). I cant center the ceiling mount due to acoustic panels in the ceiling, let me know if this is confusing and i'll take a picture.

Only questions remaining is if I understood your design idea right, and if I should spline mount or free mount the exciter. I'm probably going to build it to be able to do both, and I can listen and decide for myself!

Thanks again for your suggestion, and please let me know if this all sounds right to you or not!

Attachments

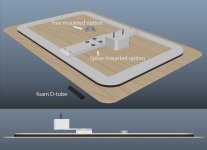

update, not quite ready for testing yet, but I think i'll get there in a couple of days if I find the time.

I went for a full on holy with a cross to hold the frame as I felt the thin ply needed more support.

I still need to glue and round the ply corners, and i'm planning to add a extra piece of thin ply to strengthen the corners, forming triangles.

Rubber will be glued on once I assemble the frame.

For the spline option I need to cut a round hole in the wide piece for the exciter to sit in, then I can adjust the mounting depth with some spacers.

Let me know if you see anything alarming.

I went for a full on holy with a cross to hold the frame as I felt the thin ply needed more support.

I still need to glue and round the ply corners, and i'm planning to add a extra piece of thin ply to strengthen the corners, forming triangles.

Rubber will be glued on once I assemble the frame.

For the spline option I need to cut a round hole in the wide piece for the exciter to sit in, then I can adjust the mounting depth with some spacers.

Let me know if you see anything alarming.

Attachments

Only questions remaining is if I understood your design idea right...

Thanks again for your suggestion, and please let me know if this all sounds right to you or not!

kaptajn,

Yes, it looks like you understood exactly my suggestion. Your progress looks good, I sure hope it works out well!

Eric

Super work Drauk! Very cool. What is your panel material?

One thought is that your tweeter looks like it is very small and light, I wonder if you could mount it directly on your DML panel? That would give you more of a point source consistent with the midrange from the DML. Also, your DML is very large and this means it’s sensitivity will be very high relative to the little woofer you have. My guess is that it will make much more and much deeper bass than the 5in or 6in woofer you have there as an OB. Have you used a mic to measure the response and relative contributions?

A DML this big will be in the mid 90dB sensitivity and a little woofer like that with OB and baffle step loss will be sub 80dB. A very large disparity so that it probably is very over powered by the DML. My guess is that a DML this big can easily reach 30Hz at quite a nice sensitivity in the 88dB to 90dB level.

Try running the DML full range and add the tweeter as super tweeter with a 1uF high pass cap. That might be all the XO you need rather than designing this like a conventional 3 way.

One thought is that your tweeter looks like it is very small and light, I wonder if you could mount it directly on your DML panel? That would give you more of a point source consistent with the midrange from the DML. Also, your DML is very large and this means it’s sensitivity will be very high relative to the little woofer you have. My guess is that it will make much more and much deeper bass than the 5in or 6in woofer you have there as an OB. Have you used a mic to measure the response and relative contributions?

A DML this big will be in the mid 90dB sensitivity and a little woofer like that with OB and baffle step loss will be sub 80dB. A very large disparity so that it probably is very over powered by the DML. My guess is that a DML this big can easily reach 30Hz at quite a nice sensitivity in the 88dB to 90dB level.

Try running the DML full range and add the tweeter as super tweeter with a 1uF high pass cap. That might be all the XO you need rather than designing this like a conventional 3 way.

Last edited:

Your design seemed familiar, then I remembered that there was a vid on youtube where one used a 3 way with a wood type of DML for the mids and a conventional tweeter and woofer.

YouTube

Super work Drauk! Very cool. What is your panel material?

One thought is that your tweeter looks like it is very small and light, I wonder if you could mount it directly on your DML panel? That would give you more of a point source consistent with the midrange from the DML. Also, your DML is very large and this means it’s sensitivity will be very high relative to the little woofer you have. My guess is that it will make much more and much deeper bass than the 5in or 6in woofer you have there as an OB. Have you used a mic to measure the response and relative contributions?

A DML this big will be in the mid 90dB sensitivity and a little woofer like that with OB and baffle step loss will be sub 80dB. A very large disparity so that it probably is very over powered by the DML. My guess is that a DML this big can easily reach 30Hz at quite a nice sensitivity in the 88dB to 90dB level.

Try running the DML full range and add the tweeter as super tweeter with a 1uF high pass cap. That might be all the XO you need rather than designing this like a conventional 3 way.

The panel material is an acoustic sealing tile I found here:

Product - Gyprock Trade™

I thought about mounting a circular dome tweeter dead in the middle of the panel, but I opted against it not knowing the effect it would have on the panels response. I'm open to looking into a better tweeter, perhaps a wave guide horn type because of the simplicity of retrofitting. I'm not sure if having a high crossover point at ~8khz impacts the significance of mounting in the panel ?

In my testing with the dayton exciters on these panels, there is little to no response from about 150 down, the units begin to collide with the panel and cause horrific distortion if powered to moderate levels without cutting the low end off. I've got an exciter graveyard to prove it :'D

Sensitivity of the woofer is an issue at the moment yes, this enclosure is around 180L and has about 20cm^2 of open face ventilation. Not ideal, but I've no problem mounting a box around the back of it. I left it like this to observe if the accoustic dampening (4 layers of upholstered bath towels) had any effect on an open baffle. Hopefully with this it will prevent cone excursion which occurs at moderate to high volume at the moment. Otherwise a different driver might be better, something like the tang band w6 6.5.

Edit: Also I don't own a mic appropriate for response work, I modelled on the combined response of a 2 5ths 3 5ths and a center mount panel of the same dimensions and exciter model provided by the Tech Ingredients youtube channel. And fiddling with component values to arrive at something that works full range.

Hopefully my tri-amping scheme will keep it phase aligned and level matched across the full range. Would love to measure, anyone wanna lend me a mic? :'D

Last edited:

Your design seemed familiar, then I remembered that there was a vid on youtube where one used a 3 way with a wood type of DML for the mids and a conventional tweeter and woofer.

YouTube

Hey, that's very groovy. I hadn't stumbled on this yet, though there aren't many DML videos online.

I wonder what sort of job of the mids it does and what range, it's such a small and rigid piece of material.

Microphones are not expensive. If you have a sound interface with XLR and phantom power this will be fine:

Dayton Audio EMM-6 Electret Measurement Microphone

Or get a UMIK-1 USB mic from miniDSP. About $90.

This is a critical tool of you want to design speakers and crossovers.

You can also make one using a WM-60A $5 Panasonic capsule - same active element in most of these mics. More info in your own DIY mic on SL’s website.

System Test

Dayton Audio EMM-6 Electret Measurement Microphone

Or get a UMIK-1 USB mic from miniDSP. About $90.

This is a critical tool of you want to design speakers and crossovers.

You can also make one using a WM-60A $5 Panasonic capsule - same active element in most of these mics. More info in your own DIY mic on SL’s website.

System Test

The U-mik is the one. Load up REW (free), plug in the mic (USB) load the calibration file when prompted, and you're in business.Microphones are not expensive. If you have a sound interface with XLR and phantom power this will be fine:

Dayton Audio EMM-6 Electret Measurement Microphone

Or get a UMIK-1 USB mic from miniDSP. About $90.

This is a critical tool of you want to design speakers and crossovers.

You can also make one using a WM-60A $5 Panasonic capsule - same active element in most of these mics. More info in your own DIY mic on SL’s website.

System Test

Microphones are not expensive. If you have a sound interface with XLR and phantom power this will be fine:

Dayton Audio EMM-6 Electret Measurement Microphone

Or get a UMIK-1 USB mic from miniDSP. About $90.

This is a critical tool of you want to design speakers and crossovers.

You can also make one using a WM-60A $5 Panasonic capsule - same active element in most of these mics. More info in your own DIY mic on SL’s website.

System Test

I think a diy mic is a brilliant idea, I've got an altoid tin that circuit would be perfect for! Excited!

I knew a mic was essential but always assumed they were prohibitively expensive. Silly old bear.

I tried messing around with making my own and it’s not worth it. It’s a tool. We don’t make our own DMM’s or screwdrivers do we?

You can buy the UMIK or EMM-6 from third party Cross Spectrum Labs for additional $20 or so and they independently calibrate it. You will also need a basic $20 SPL meter to periodically calibrate the absolute amplitude of the microphone.

You can buy the UMIK or EMM-6 from third party Cross Spectrum Labs for additional $20 or so and they independently calibrate it. You will also need a basic $20 SPL meter to periodically calibrate the absolute amplitude of the microphone.

Can you tell me how your design sounds and your first impressions of both pros and cons. Thanks.

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker