Can you imagine if the initial success with DIY panels focused on wood instead of 1" XPS - but was with 1/4" balsa plywood? But 1/8 spruce tone wood (thinner and denser) was so hard to come by, that no one tried it? Probably wishful thinking on my part, that it's significantly better than the 250, but I won't be satisfied unless I try the higher grades of the Owens Corning product, or learn of someone else's experience with it. Home Depot will only order a pallet of it, so I need to find a consumer of it that will sell me a single sheet.

I've tried almost every material that I could imagine and most everything that has been suggested by other experimenters and never found the sound that I was looking for until my discovery of wood/canvas..

There isn't many 24" X 30" flat wall mount (Wireless) Bluetooth speakers configured in Stereo that has the ability to reproduce enough separation to be heard at 10' with the clarity and SPL of most modest bookshelf speakers..

Just sayin'...

There isn't many 24" X 30" flat wall mount (Wireless) Bluetooth speakers configured in Stereo that has the ability to reproduce enough separation to be heard at 10' with the clarity and SPL of most modest bookshelf speakers..

Just sayin'...

Not too long ago I cam across a website for a commercial flat panel speaker that now I can't recall the name of. The distinguishing feature of this speaker was that the panels had had slits in the panel edges, and the slits were oriented at various angles. Also, it appeared that the panels were end grain balsa covered with fiberglass or carbon fiber. Ostensibly, the slits were intended to minimize edge reflections. Does anyone recall what make of speaker this is?

Thanks,

Eric

Thanks,

Eric

I've tried almost every material that I could imagine and most everything that has been suggested by other experimenters and never found the sound that I was looking for until my discovery of wood/canvas..

There isn't many 24" X 30" flat wall mount (Wireless) Bluetooth speakers configured in Stereo that has the ability to reproduce enough separation to be heard at 10' with the clarity and SPL of most modest bookshelf speakers..

Just sayin'...

I have a few questions regarding your very interesting picture frame design.

I've been inspired by this forum and others and ordered 4 daex30hesf 4 ohm to go in my ceiling for atmos, and am deciding between two design.

A large consideration is aesthetics/WAF as I have spend all my WAF points on towers, center and wall mounted back channels in our living room (5.0)

As I have covered parts of my ceiling in acoustic panels at 2'x2' (commercial mineral wool ecophon 40mm or 1.57" glued directly to the ceiling) the speaker panels should sit next to or on top of these and blend in as best they can. I have decided they should not extend down much further then 80mm / 3.15".

first option is the 2'x2' xps panels screwed into a piece of 1.57' spacing wood which is then screwed into the concrete ceiling. I've seen something similar done in an early post.

I would cut a hole in the existing acoustic panel and place the speaker directly below it to absorb the back of the panel.

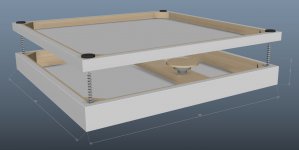

The second option is your picture frame design, but i'm uncertain if this would work, so I've sketched it out in 3D so you can see what I mean.

My design is a 2'x2' (60x60 cm) and 3.15" (8 cm) deep frame that will be flush mounted to the ceiling. This frame could also contain a thinner (0.79") acoustic mineral wool panel as seen in the picture.

So my questions would be if you this design could work to a reasonable degree, or the compromise of distance to wall is not worth it, and I should go with the XPS without frame for this purpose?

Eventually I am planning to build a subwoofer sofa table to cover the lows better, but that will like happen after the panels.

My system is Quad Z4 fronts, ZC center and Z1's for backs powered by a marantz 7013.

I sincerely hope you feel inclined to share your thoughts on this, and will be happy to alter my 3D design if any good suggestions come up. I also promise to share my experience and pictures once I decide on a build.

Cheers!

Attachments

It's interesting Göbel's DML drivers are relatively small, only a square about 40 centimeters or about 15 inches.

I agree. I was thinking their panels are actually even smaller than that. My best guess was about 12" x 9" or more likely 30cm x22.5 cm. Anybody know for sure?

Eric

Can you imagine if the initial success with DIY panels focused on wood instead of 1" XPS - but was with 1/4" balsa plywood? But 1/8 spruce tone wood (thinner and denser) was so hard to come by, that no one tried it?

I like your thinking. I also feel the need to try everything! But IMHO PS foam is the wrong direction for you attention.

My own observations are that a light 5 mm plywood provides the best frequency response over a wide frequency range but lacks volume (due to its weight), and PS foam provides the loudest response, but lacks frequency range, especially at the high end (because it's too soft).

I've tried PS foam up to about 40 kg/m3. Response drops of quickly after about 3 Khz. Denser foam will probably do better, but I doubt it will do more than 4 or 5 Khz.

I'm more optimistic that a better answer is a composite with wood veneer skin and a lightweight core (nomex? end grain balsa?). Such a composite should be hard enough for HF response and stiff/light enough for good efficiency/SPL.

I've made some 3/16 balsa plywood, and it's not bad. I'd love to try 1/8 spruce tonewood. Have you?

Eric

@ kaptajnThomsen..

Great graphics! Thank You..

I'm still experimenting with different materials/configurations and finding good contributions to the goal from many. Trying to find the magic combination is tough..

One thing I have noticed and mentioned here a good while ago. The quality of the sound is better on the side of the material the exciter is mounted to, not on the opposite side that everyone seems to design to/for. There is a loss of treble response "through" the material that is very noticeable to me. In some cases, through is good but a slight loss of overall mid/high sensitivity can be expected but these things are very sensitive to EQ. I ask anyone who has constructed a flat panel unit without a frame to add to this. Many times I've said.. "Dang.. It sounds better from the back!"

I've given up on foam of any type. I have found that a thin and relativity small piece of wood is my best choice and a surround of flexible material gives me the best results. The size and shape of the wood adjusts the response and a frame around the outer parameter increases the bass response. KT.. Imagine your first illustration "flipped" with the surface of the material the exciter is mounted to facing down in a frame. This is my next project..

Give me some time before you do any huge effort and I will get back to you. I urge others to experiment also..

Great graphics! Thank You..

I'm still experimenting with different materials/configurations and finding good contributions to the goal from many. Trying to find the magic combination is tough..

One thing I have noticed and mentioned here a good while ago. The quality of the sound is better on the side of the material the exciter is mounted to, not on the opposite side that everyone seems to design to/for. There is a loss of treble response "through" the material that is very noticeable to me. In some cases, through is good but a slight loss of overall mid/high sensitivity can be expected but these things are very sensitive to EQ. I ask anyone who has constructed a flat panel unit without a frame to add to this. Many times I've said.. "Dang.. It sounds better from the back!"

I've given up on foam of any type. I have found that a thin and relativity small piece of wood is my best choice and a surround of flexible material gives me the best results. The size and shape of the wood adjusts the response and a frame around the outer parameter increases the bass response. KT.. Imagine your first illustration "flipped" with the surface of the material the exciter is mounted to facing down in a frame. This is my next project..

Give me some time before you do any huge effort and I will get back to you. I urge others to experiment also..

@ kaptajnThomsen..

Great graphics! Thank You..

I'm still experimenting with different materials/configurations and finding good contributions to the goal from many. Trying to find the magic combination is tough..

One thing I have noticed and mentioned here a good while ago. The quality of the sound is better on the side of the material the exciter is mounted to, not on the opposite side that everyone seems to design to/for. There is a loss of treble response "through" the material that is very noticeable to me. In some cases, through is good but a slight loss of overall mid/high sensitivity can be expected but these things are very sensitive to EQ. I ask anyone who has constructed a flat panel unit without a frame to add to this. Many times I've said.. "Dang.. It sounds better from the back!"

I've given up on foam of any type. I have found that a thin and relativity small piece of wood is my best choice and a surround of flexible material gives me the best results. The size and shape of the wood adjusts the response and a frame around the outer parameter increases the bass response. KT.. Imagine your first illustration "flipped" with the surface of the material the exciter is mounted to facing down in a frame. This is my next project..

Give me some time before you do any huge effort and I will get back to you. I urge others to experiment also..

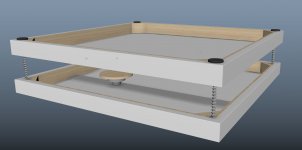

I've made another quick sketch of your suggestion, but in order to both mount the exciter and cover it for WAF, there is a sandwich design going on.

On the downside the membrane is extremely close to the wall/ceiling and there now seems to be no room for an absorber in the design, or it will have to be quite thin.

The inner membrane could be any material, not just cotton canvas.

The outer cover would obviously also have to be speaker cloth, which in my case is fine, but if you want an image on there, you will need it to be printed.

Height could be reduced if the exciter could be mounted on something thin and strong, like a steel bar.

Attachments

Last edited:

I've made another quick sketch of your suggestion, but in order to both mount the exciter and cover it for WAF, there is a sandwich design going on.

On the downside the membrane is extremely close to the wall/ceiling and there now seems to be no room for an absorber in the design, or it will have to be quite thin.

The inner membrane could be any material, not just cotton canvas.

The outer cover would obviously also have to be speaker cloth, which in my case is fine, but if you want an image on there, you will need it to be printed.

Height could be reduced if the exciter could be mounted on something thin and strong, like a steel bar.

I made a quick example of a thinner bar to hold the exciter in place, its 4mm, attaching it to the wood frame shouldn't be too difficult.

This allows for two same-sized 1.6inch canvases to be stacked which makes pre-bought frames an option, still the outer canvas will need to be speaker cloth.

Have you tried holding one of your exciters on the front of a canvas and put it up against a wall? How do you think that will sound?

Attachments

I like your thinking. I also feel the need to try everything! But IMHO PS foam is the wrong direction for you attention.

My own observations are that a light 5 mm plywood provides the best frequency response over a wide frequency range but lacks volume (due to its weight), and PS foam provides the loudest response, but lacks frequency range, especially at the high end (because it's too soft).

I've tried PS foam up to about 40 kg/m3. Response drops of quickly after about 3 Khz. Denser foam will probably do better, but I doubt it will do more than 4 or 5 Khz.

I'm more optimistic that a better answer is a composite with wood veneer skin and a lightweight core (nomex? end grain balsa?). Such a composite should be hard enough for HF response and stiff/light enough for good efficiency/SPL.

I've made some 3/16 balsa plywood, and it's not bad. I'd love to try 1/8 spruce tonewood. Have you?

Eric

If I am correct, 40 kg/cubic meter = 2.5 lbs/cubic foot. That definitely would be a quite high density of PS. How thick was it and did you sand the skin off and coat it? I have not tried any wood yet, but you have me wanting to. I have gotten great results with the 1" Foamular 250, sanded and coated. The high end extension is good but a little peaky/shouty in the mid-range.

I ordered two PUI exciters from Newark in the beginning of January. Eventually (after many emails) I had to cancel the order since Newark claims my Bank keep declining the transaction. They’ve tried twice. Yet, I’ve been using the same Visa card buying stuff from all over the world and nobody else seems to have a problem taking my money. Anyway, goodbye Newark - there are other suppliers for PUI exciters like DigiKey and Mouser.

Don’t know if you have seen the PUI white paper. Nothing new really, but what I found interesting is that they do not mention DML once and their test/sample panels are pretty small – 400 x 200 mm. Also their mount positions are interesting – suggesting that you could mount up to 4 exciters on one such a small panel.

Don’t know if you have seen the PUI white paper. Nothing new really, but what I found interesting is that they do not mention DML once and their test/sample panels are pretty small – 400 x 200 mm. Also their mount positions are interesting – suggesting that you could mount up to 4 exciters on one such a small panel.

Attachments

I ordered two PUI exciters from Newark in the beginning of January. Eventually (after many emails) I had to cancel the order since Newark claims my Bank keep declining the transaction. They’ve tried twice. Yet, I’ve been using the same Visa card buying stuff from all over the world and nobody else seems to have a problem taking my money. Anyway, goodbye Newark - there are other suppliers for PUI exciters like DigiKey and Mouser.

Don’t know if you have seen the PUI white paper. Nothing new really, but what I found interesting is that they do not mention DML once and their test/sample panels are pretty small – 400 x 200 mm. Also their mount positions are interesting – suggesting that you could mount up to 4 exciters on one such a small panel.

Dayton Audio DAEX19CT-4 Coin Type 19mm Vented Exciter 5W 4 Ohm

I'm not sure what the policy of Billionsound is in terms of samples versus minimum order quantity, but they manufacture PUI and Dayton exciters, as well as others. Ordering from South Africa it may be that obtaining them directly might be faster and less expensive. I get samples fairly quickly here in the States.

Saw this in the news.

Continental applying exciter tech and DML to cars.

Using exciters on the dashboard to create a sound system without the use of typical drivers.

Get the best sound – even without speakers

Continental applying exciter tech and DML to cars.

Using exciters on the dashboard to create a sound system without the use of typical drivers.

Get the best sound – even without speakers

Saw this in the news.

Continental applying exciter tech and DML to cars.

Using exciters on the dashboard to create a sound system without the use of typical drivers.

Get the best sound – even without speakers

I wondered when we'd see this. In my crawl through the patents I saw maybe a couple of dozen patents that relate to exciting the interior panels of cars.

Worth a read if you're thinking of making irregular shaped panels which are not necessarily flat. I'll get around to it some day.

Don’t know if you have seen the PUI white paper.

twocents,

There may be some good tidbits in there but I'm not too impressed with this white paper.

quote 1:

Many product designers mount speakers on bosses or stand-offs that prevent an annular

seal from being created around the perimeter of the speaker’s frame or diaphragm. This

introduces cancelation as the front of the speaker’s diaphragm is free to interact with the

rear of the speaker’s diaphragm; creating loss of low frequency reproduction.

I guess they are talking about conventional piston speakers here, but who mounts drivers on standoffs that prevent creating a seal around the diaphram?? Maybe I am misunderstanding what they are talking about here..

quote 2:

The ideal material to use with an exciter would be lightweight, dense, and able to bend.

Lightweight and dense are opposites! I think they mean "hard" instead of dense.

And "able to bend"? Everything is able to bend! I suppose they mean "bend easily", but frankly, that's contrary to the normal advice to use a stiff, not soft panel.

Concerning their graphs that show the thicker panel giving more low frequency output than the thin one....I can imagine cases where that could happen, but my experience is that the opposite is more common, that is, thinner panels providing more output on the low end.

Take this, like everything you read about panel speakers, with a big grain of salt, and believe nothing until you've tried it and verified it yourself!

Thank you. Never thought of going that route - might give it a try.I'm not sure what the policy of Billionsound is in terms of samples versus minimum order quantity, but they manufacture PUI and Dayton exciters, as well as others. Ordering from South Africa it may be that obtaining them directly might be faster and less expensive. I get samples fairly quickly here in the States.

- Home

- Loudspeakers

- Full Range

- A Study of DMLs as a Full Range Speaker