DD,

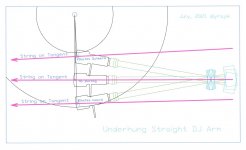

I thought you were talking about skating for regular pivot arms. But if you were talking about tangential pivot arms, Klaus' statement is correct. And, both the string test and Conrad's condition are correct, too. Take Reed 5A as an example. Please see the image.

The green line indicates the string test and Conrad's condition. If the green line is a string, pull the string, the arm will move sideways. For Conrad's condition, the green doesn't intersect the center of the pivot. The arm will skate.

For Klaus' statement, the red shows that the line through the tip of the cartridge to the center of the pivot is not tangent to the groove. Therefore, the arm will skate.

Although I said that I did expect the arm didn't skate, I thought the arm might still skate. This is why I want to build a clone of Reed 5A.

All I was trying to approve that the string test and Conrad's condition were not the universal standards for judging if a tonearm skates. In the case of DJ arm, both standards get incorrect conclusions. Both standards are based on arm's offset. In fact, offset is irrelevant to skating.

For Klaus' statement, it is not correct if a tonearm has an underhang. Yes. I do understand that we haven't seen a working tonearm has an underhang. It probably will never be a tonearm with an underhang.

If I have to choose, I rather take Klaus' statement about skating as standard because his statement can be applied to a DJ arm as well.

I thought you were talking about skating for regular pivot arms. But if you were talking about tangential pivot arms, Klaus' statement is correct. And, both the string test and Conrad's condition are correct, too. Take Reed 5A as an example. Please see the image.

The green line indicates the string test and Conrad's condition. If the green line is a string, pull the string, the arm will move sideways. For Conrad's condition, the green doesn't intersect the center of the pivot. The arm will skate.

For Klaus' statement, the red shows that the line through the tip of the cartridge to the center of the pivot is not tangent to the groove. Therefore, the arm will skate.

Although I said that I did expect the arm didn't skate, I thought the arm might still skate. This is why I want to build a clone of Reed 5A.

All I was trying to approve that the string test and Conrad's condition were not the universal standards for judging if a tonearm skates. In the case of DJ arm, both standards get incorrect conclusions. Both standards are based on arm's offset. In fact, offset is irrelevant to skating.

For Klaus' statement, it is not correct if a tonearm has an underhang. Yes. I do understand that we haven't seen a working tonearm has an underhang. It probably will never be a tonearm with an underhang.

If I have to choose, I rather take Klaus' statement about skating as standard because his statement can be applied to a DJ arm as well.

Attachments

Last edited:

Jim, the string test and Conrad's theory came about was earlier in my thread when I introduced all these new commercial products with multiple pivots and linkages and in my more naive days I was elated to have discovered the possibility of tangential tracking without air bearings, rollers, and servos. But I neglected the resultant skating force and underestimated its factor in sonic influence.

Conrad warned me earlier with his straight line theory and then later on Ray introduced his string test to keep me honest. It is in the context of the development of that thread that the two methods came about. Applying them to any self proclaimed pivoting tangential tracking arm invariably shows they can skate.

Offset or no offset does not matter because you can have a completely spherical stylus tip of a mono cartridge, for example, that makes offset meaningless. Simply put, tangency without skating only happens when the spindle to stylus to pivot point creates a right triangle but in a traditional pivot arm that only happens at two null points, which also happens in your Thales circle test and chart or those Wally test videos. But in a multiple pivot design a la Reed 5A that kind of right triangle can not be formed therefore it can skate.

I have looked every known product of dual pivot design and concluded they all skate, some more than others. (The only outlier is the Klaudio arm which still baffles me with its mechanical movement. It's not exactly an "articulated" arm per se but more of a parallelogram design to create straight horizontal movement in a passive way.) With those two methods I can look at almost any dual pivot arm and determine without charts or grahics it can skate when antiskating device is not employed. Yes, you have found an interpretive loophole in the string test with the null points but you need the arm to track tangentially across the entire disc, not just two grooves.

There are tonearms with underhang by the way. The Thales Easy model is one that sets the null point in the middle of the groove area and goes underhang at the beginning and tangent in the middle and then underhang towards the end. The Impossible tonearm by JR Audio is another example.

Conrad warned me earlier with his straight line theory and then later on Ray introduced his string test to keep me honest. It is in the context of the development of that thread that the two methods came about. Applying them to any self proclaimed pivoting tangential tracking arm invariably shows they can skate.

Offset or no offset does not matter because you can have a completely spherical stylus tip of a mono cartridge, for example, that makes offset meaningless. Simply put, tangency without skating only happens when the spindle to stylus to pivot point creates a right triangle but in a traditional pivot arm that only happens at two null points, which also happens in your Thales circle test and chart or those Wally test videos. But in a multiple pivot design a la Reed 5A that kind of right triangle can not be formed therefore it can skate.

I have looked every known product of dual pivot design and concluded they all skate, some more than others. (The only outlier is the Klaudio arm which still baffles me with its mechanical movement. It's not exactly an "articulated" arm per se but more of a parallelogram design to create straight horizontal movement in a passive way.) With those two methods I can look at almost any dual pivot arm and determine without charts or grahics it can skate when antiskating device is not employed. Yes, you have found an interpretive loophole in the string test with the null points but you need the arm to track tangentially across the entire disc, not just two grooves.

There are tonearms with underhang by the way. The Thales Easy model is one that sets the null point in the middle of the groove area and goes underhang at the beginning and tangent in the middle and then underhang towards the end. The Impossible tonearm by JR Audio is another example.

Let’s take a DJ tonearm without offset but with an overhang. The DJ arm will pass the string text. If you pull the string, the arm won’t move sideways. The DJ arm will meet Conrad’s condition, too. A line through the headshell will intersect the center of the pivot.

The DJ tonearm will pass the string test at only one point on the record.

Conrad's condition is not a general condition for skating.

All I was trying to approve that the string test and Conrad's condition were not the universal standards for judging if a tonearm skates. In the case of DJ arm, both standards get incorrect conclusions. Both standards are based on arm's offset. In fact, offset is irrelevant to skating.

I can’t help but get the feeling that you have a specific vendetta against my string test. I hope I am misreading that, in which case I apologize. I am going to be extremely careful to keep this technical by limiting my response to presenting facts and data.

Your frustration with the string test is due to your applying it incorrectly, and are therefore mis-diagnosing what happens when you use it to test straight DJ arms.

The string test was originally conceived to be applied to offset arms and tangential pivot arms, both of which had/have the goal of maintaining tangency across the playing area of the disc. Then, straight DJ arms bubbled up in the witches brew and entered the discussion from out of left field. Your misapplication of the string test has been, shall we say, throwing you for a loop. As clarified in subsequent posts by myself and others, you have to pull the string tangentially to the stylus contact point, which is not necessarily in line with the headshell. I have outlined pertinent historical mileposts to clarify this and present them below.

Post #11 4-28-10, Conrad Hoffman’s original criterion: “If you draw a line, or at least a vertical plane, through the stylus/cartridge and it doesn't intersect the arm pivot, you've got forces you don't want.”

https://www.diyaudio.com/forums/ana...-tangential-pivot-tonearms-2.html#post2169512

Post #949 04-07-15, diyrayk’s original String Test challenge: “Take a string 12 or longer, it doesn’t really matter, and tie it to the headshell or the cartridge body so that it stretches straight out from the cartridge and in line with the stylus.”

https://www.diyaudio.com/forums/ana...tangential-pivot-tonearms-95.html#post4285998

post #1149 03-22-17 alighiszem proposes his ‘yarn’ test: “if you bind a piece of cotton yarn on the tonearm and pull it in the direction the friction force would pull” Note he states more clearly than I originally did that you have to pull in the direction of the friction force which means, in other words, tangentially.

https://www.diyaudio.com/forums/ana...angential-pivot-tonearms-115.html#post5027196

post #1156 03-22-17 “Yes, the simulated 'friction force' is tangential, but if the tangential string force vector is offset or not in line with the pivot, be it fixed or virtual, the tangential friction force will resolve itself into some rotary component about the pivot point, and this manifests itself as skating.” At this point I still referred to being in line with the headshell, but also began to emphasize that we are simulating friction force and for that the string has to be pulled ‘tangentially’, which is a clearer way of stating the groove friction force direction.

https://www.diyaudio.com/forums/ana...angential-pivot-tonearms-116.html#post5027399

post #120 06-19-21 Point of clarification: The discussion has veered off course and I have to clarify the frame of reference for tangency. 2wice proposes reframing the test as “String Test 2.0”, which I did.

https://www.diyaudio.com/forums/ana...tracking-pivoting-tonearm-12.html#post6695795

post #36 07-14-21 Straight Tracker further clarifies that the frame of reference for “tangential” should be more precisely defined as the tangential location of the stylus on a “concentric circle”. Excellent! With that we are now up to “String Test 2.1”.

https://www.diyaudio.com/forums/ana...ial-tracking-pivot-tonearm-4.html#post6720348

Summary:

If we take Straight Tracker’s precise definition of “tangential” and substitute that precise definition in my “String Test 2.1”, alighiszem’s ‘yarn’ test, Conrad Hoffman’s criterion, and Klaus Rampelmann’s explanation of skating, then there is no conflict or incompatibility among these test criteria for skating, and by all these methods, the DJ arm FAILS the test. All four methods work as advertised if you use the correct frame of reference for tangency, and the physics of the universe is happy. The nice thing about String Test 2.1 is that with a simple piece of string you can walk up to a tonearm and determine if it will skate even if you don’t know where exactly the pivot is, which is sometimes not clear on a complex mechanism such as a KLAUDIO arm.

Ray K

Attachments

Ray,

I don’t have any vendetta against your string test and had no intention to discuss skating in this thread. I was merely replying DD’s post that quoted Klaus’ statement and mentioned your string test and Conrad’s condition.

Your string test V1 and Conrad’s condition are in fact the same thing. Both don’t include friction between the cartridge and groove at all.

For string test version 1, it will fail in two cases. 1, a DJ arm. 2, an arm with offset and an underhang, too. Since you updated your string test to V2.1 now, you must be aware of its shortcomings.

Before we start to discuss V2.1, I would ask only one question.

How do you determine that your string is tangent to the groove? If it is a test, you have to actually perform such a test on a tonearm. I would like to see you actually perform such a test before we will discuss it further.

Jim

I don’t have any vendetta against your string test and had no intention to discuss skating in this thread. I was merely replying DD’s post that quoted Klaus’ statement and mentioned your string test and Conrad’s condition.

Your string test V1 and Conrad’s condition are in fact the same thing. Both don’t include friction between the cartridge and groove at all.

For string test version 1, it will fail in two cases. 1, a DJ arm. 2, an arm with offset and an underhang, too. Since you updated your string test to V2.1 now, you must be aware of its shortcomings.

Before we start to discuss V2.1, I would ask only one question.

How do you determine that your string is tangent to the groove? If it is a test, you have to actually perform such a test on a tonearm. I would like to see you actually perform such a test before we will discuss it further.

Jim

Pseudo-tangential without anti-skating

Hi directdriver,

I have to admit that I did not know the Klaudio before. After having had a look at it, I think its workings are along the same line as with the Thales Easy. Both arms display underhang for most of the tracking area on the record, except for one point, more or less half way between outer- and innermost groove. Therefor both these arms are pseudo-tangential most of the time. However, at exactly three points the offset-mechanism (made possible by the second /auxiliary and more or less parallel tonearm) exactly reduces the tracking angle error to zero. The rest of the time it nearly makes the arm tangential by providing compensation (but a small error remains). Of course the longer Klaudio tonearm (12" vs. 9) has a somewhat easier task: the offset angle is smaller by nature and therefor the residual skating forces on the Klaudio are even smaller than is the case for the Thales Easy.

Both arms don't use anti-skating. Probably because it doesn't make much difference as the skating forces are already small (ranging from approx 25% of the forces of a standard pivoted 9" arm at the outer groove, going down to 0 halfway, and later climbing up to approx 25% again, but in outward direction at the innermost groove. There the arm has a negative offset angle. Looks a bit strange. But hey, apparently it all works very well, if the reviews (of both arms actually) are worth anything..

best regards,

Mark

.....

I have looked every known product of dual pivot design and concluded they all skate, some more than others. (The only outlier is the Klaudio arm which still baffles me with its mechanical movement. It's not exactly an "articulated" arm per se but more of a parallelogram design to create straight horizontal movement in a passive way.) With those two methods I can look at almost any dual pivot arm and determine without charts or grahics it can skate when antiskating device is not employed. Yes, you have found an interpretive loophole in the string test with the null points but you need the arm to track tangentially across the entire disc, not just two grooves.

There are tonearms with underhang by the way. The Thales Easy model is one that sets the null point in the middle of the groove area and goes underhang at the beginning and tangent in the middle and then underhang towards the end. The Impossible tonearm by JR Audio is another example.

Hi directdriver,

I have to admit that I did not know the Klaudio before. After having had a look at it, I think its workings are along the same line as with the Thales Easy. Both arms display underhang for most of the tracking area on the record, except for one point, more or less half way between outer- and innermost groove. Therefor both these arms are pseudo-tangential most of the time. However, at exactly three points the offset-mechanism (made possible by the second /auxiliary and more or less parallel tonearm) exactly reduces the tracking angle error to zero. The rest of the time it nearly makes the arm tangential by providing compensation (but a small error remains). Of course the longer Klaudio tonearm (12" vs. 9) has a somewhat easier task: the offset angle is smaller by nature and therefor the residual skating forces on the Klaudio are even smaller than is the case for the Thales Easy.

Both arms don't use anti-skating. Probably because it doesn't make much difference as the skating forces are already small (ranging from approx 25% of the forces of a standard pivoted 9" arm at the outer groove, going down to 0 halfway, and later climbing up to approx 25% again, but in outward direction at the innermost groove. There the arm has a negative offset angle. Looks a bit strange. But hey, apparently it all works very well, if the reviews (of both arms actually) are worth anything..

best regards,

Mark

Uh, my mistake

In addition to the previous message: I missed the most important part in the discription given by Klaudio.

"Klaudio's tonearms are true mechanical tangential tonearms, providing the advantages of linear arms without the cost or complexity of air bearings. To achieve 0-degrees of tracking error, they not only pivot but glide longitudinally on ultra-precise bearings. This keeps the needle on an ideal tangent, which can be confirmed with the included laser-projection tool."

Not what I concluded at all. I just wonder why use pivots and gliding bearings? If the latter are good enough, one might also make a lighter and stiffer linear arm with just those "ultra-precise" bearings... Intriguing design this Klaudio tonearm

greetings, Mark

In addition to the previous message: I missed the most important part in the discription given by Klaudio.

"Klaudio's tonearms are true mechanical tangential tonearms, providing the advantages of linear arms without the cost or complexity of air bearings. To achieve 0-degrees of tracking error, they not only pivot but glide longitudinally on ultra-precise bearings. This keeps the needle on an ideal tangent, which can be confirmed with the included laser-projection tool."

Not what I concluded at all. I just wonder why use pivots and gliding bearings? If the latter are good enough, one might also make a lighter and stiffer linear arm with just those "ultra-precise" bearings... Intriguing design this Klaudio tonearm

greetings, Mark

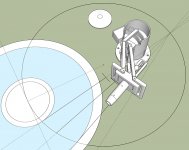

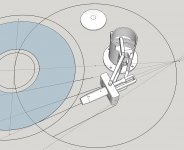

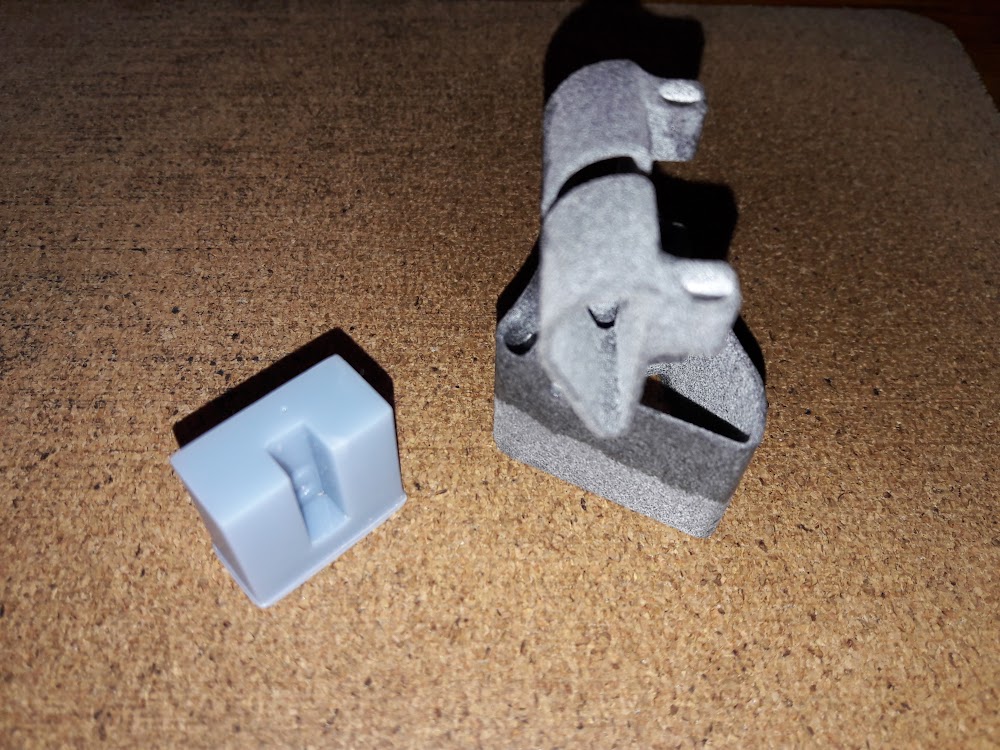

I updated the title for this thread. I planned to build a clone of Reed 5A originally to prove if Reed 5A skates. However, in the process, I start to study its geometry and found my own geometries for new tangential pivot arms. Once I found my own plan, I am so reluctant to just copy someone's work and decided to build my own. Still, my own arms can still be used to prove if the arms skate since both my tonearms and Reed 5A have fallen the same category by the skating definition of Klau.

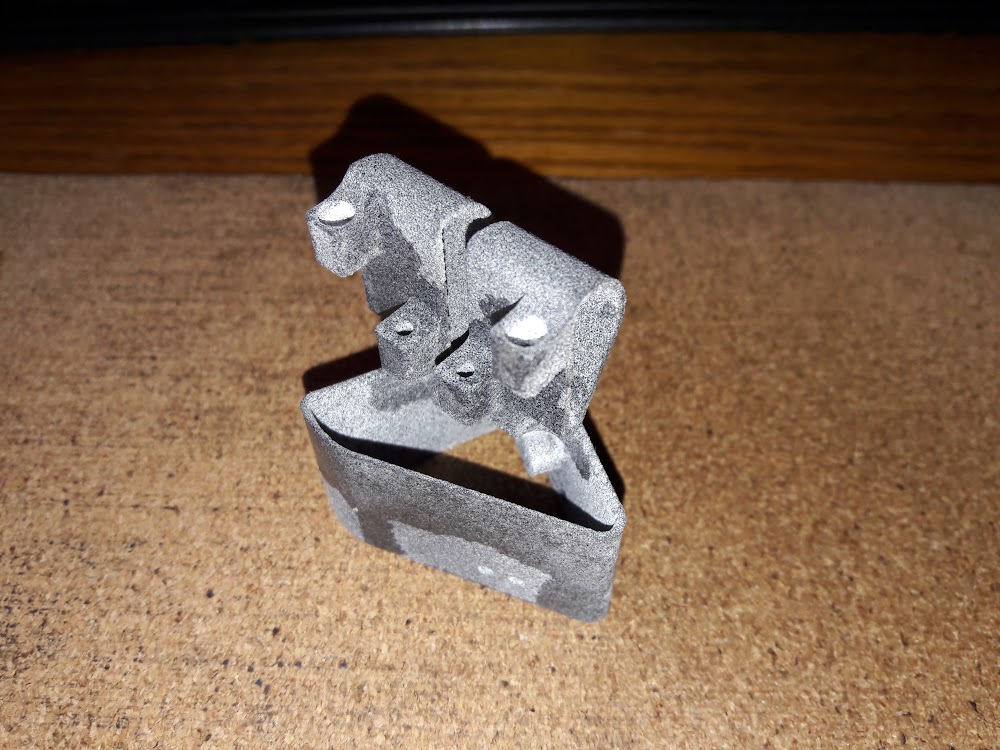

I designed two plans and am not sure which one I will make at this moment. Both arms will have a silicone damping device that is built into the base. Both arms will utilize a magnetic counterweight and be 3d printed. Ideally, they will be printed in aluminum, but the costs are too high. So, it will be printed in ABS.

I designed two plans and am not sure which one I will make at this moment. Both arms will have a silicone damping device that is built into the base. Both arms will utilize a magnetic counterweight and be 3d printed. Ideally, they will be printed in aluminum, but the costs are too high. So, it will be printed in ABS.

Attachments

Nice work Jim

Looking good, if I may suggest printing in Multi Jet Fusion if possible. It is not supper pricey, but the tolerances with nylon MJF are waaaay more accurate.

It is what I've been using to great effect.

Your fitting will be better and the parts are production ready with no post-processing needed.

You can also get any colour you want, super trippy rainbow unicorn fart prints?

No problem.

It also weights less than ABS and you are free to design elements without regards for print support or print orientation.

1 mm wall thickness, about 4g in natural colour.

mSLA Resin assembly jig, also about 4g. Much stronger than both SLS and MJF, costs more though.

Good Luck!

Looking good, if I may suggest printing in Multi Jet Fusion if possible. It is not supper pricey, but the tolerances with nylon MJF are waaaay more accurate.

It is what I've been using to great effect.

Your fitting will be better and the parts are production ready with no post-processing needed.

You can also get any colour you want, super trippy rainbow unicorn fart prints?

No problem.

It also weights less than ABS and you are free to design elements without regards for print support or print orientation.

1 mm wall thickness, about 4g in natural colour.

mSLA Resin assembly jig, also about 4g. Much stronger than both SLS and MJF, costs more though.

Good Luck!

Attachments

Hi 2wice,

I have very little knowledge about 3d printing material and methods. I got my education on printing materials from youtube. I saw a video about 25% carbon with nylon printing material. It was very intriguing. Such material must have nice physical characters to resist vibration. But I have no idea where I can get the parts printed with carbon nylon and don't know the cost.

I will take a look at nylon material, too.

Jim

I have very little knowledge about 3d printing material and methods. I got my education on printing materials from youtube. I saw a video about 25% carbon with nylon printing material. It was very intriguing. Such material must have nice physical characters to resist vibration. But I have no idea where I can get the parts printed with carbon nylon and don't know the cost.

I will take a look at nylon material, too.

Jim

This looks like Nylon 3d printed.

Probably PA12 SLS, it looks more porous than MJF.

You can get a very quick quote from here Shapeways MJF PA 12

Might be worth a look for a local (to you) 3D printing vendor, as they are sometimes a lot cheaper.

Probably PA12 SLS, it looks more porous than MJF.

You can get a very quick quote from here Shapeways MJF PA 12

Might be worth a look for a local (to you) 3D printing vendor, as they are sometimes a lot cheaper.

Attachments

Both arms will have a silicone damping device that is built into the base.

This looks like a good start. I like the way you are hiding the oil trough in the base. I assume there will be a cover on top of the base?

Sincerely,

Ralf

I have found a place to print my tonearm. All critical parts will be printed in Markforged Onyx, nylon with carbon fiber, with 100% infill. The base will be printed in MJF nylon. But I am not sure why they don't ask me to specify infill for MJF nylon. I guess it will be solid.

Solid is probably best. Some recent research exploring the damping properties of TPM surfaces, of which Gyroid seems to be a popular 3D printing infill, conveniently found Gyroid performed best of all at damping standing waves. The topology had more impact on damping than material choice. Here is the bonkers part, damping increases with a decrease in density & Gyroid is the stiffest of them all.

It might not be best to leave the choice of topology that would have an effect on the damping properties of an arm, up to a printing service.

It might not be best to leave the choice of topology that would have an effect on the damping properties of an arm, up to a printing service.

Jim,

Very good looking and promising project(s). Are you going to do one or both? If both, I'm very curious about relative performance, partly because the orientation of the primary pivots is so different - by nearly 90 degrees. I wonder what effect that may have on the arm at its fullest extention for the last few grooves.

What program are you using for the printing plans (instructions)? I know so little about the details of 3D printing, I don't know what they're called.

You could just fit a bubble into the reservoir cap. Bubble levels are very handy to have with these arms.

2wice: Are you saying Reed 3D printed the $10K Reed 5?

Very good looking and promising project(s). Are you going to do one or both? If both, I'm very curious about relative performance, partly because the orientation of the primary pivots is so different - by nearly 90 degrees. I wonder what effect that may have on the arm at its fullest extention for the last few grooves.

What program are you using for the printing plans (instructions)? I know so little about the details of 3D printing, I don't know what they're called.

You could just fit a bubble into the reservoir cap. Bubble levels are very handy to have with these arms.

2wice: Are you saying Reed 3D printed the $10K Reed 5?

Doug,

The attached image is the one I am going to make. However, both arms have some common parts so I will pre-print holes on the parts for another arm as well. If I want to make a second one later, I only need to print three additional parts.

I use Sketchup to do all the designs. You may use its web version and it is free.

I don't expect there are big differences in performance between these two arms. The other arm uses a bit more material and seems a little complicated due to the needle bearings I use. If I can source the needle bearings as Reed used for their 5A arm, my arm can even simpler. I have no plan to install a bubble level on the top of the base tower. The flat top of the base tower can be used for bubble level if I need it.

Jim

The attached image is the one I am going to make. However, both arms have some common parts so I will pre-print holes on the parts for another arm as well. If I want to make a second one later, I only need to print three additional parts.

I use Sketchup to do all the designs. You may use its web version and it is free.

I don't expect there are big differences in performance between these two arms. The other arm uses a bit more material and seems a little complicated due to the needle bearings I use. If I can source the needle bearings as Reed used for their 5A arm, my arm can even simpler. I have no plan to install a bubble level on the top of the base tower. The flat top of the base tower can be used for bubble level if I need it.

Jim

Attachments

- Home

- Source & Line

- Analogue Source

- Building a Tuthill/Reed 5A Tangential Tracking Pivot Tonearm