Naked eye or high speed camera? Interesting possibility for measurement.Cantilevers are made from some incredibly rigid materials. The compliance necessary for the response anomalies if its the cantilever would be visible.

I have a cactus needle in customs at the moment. Need to think of a suitable test scenario for that.Maybe if you are using cactus needles you could get significant flexure.

You have walked into the 'vinyl doesn't deform' club here. . With LP's the compliance is the pivot and the vinyl and the mass of the cartridge/headshell and mounting issues.

we have discussed this in the past, but the setup rig is spendy.There is a technique using an accelerometer to drive the stylus to see what is happening. Lyra among others uses it to verify performance.

What we are trying to do is work out ways that, without the sort of budget Shure brothers used to have that we can get some answers. The frequency response of some cartridges doesn't match the usual models so something is missing from those models. Bit of fun to work out what!I'm not sure what is to be learned from measuring the cartridge inductance in parallel with a resistor that can't be determined with a simulation. The loss pathways between the mechanical energy in and electrical energy out are huge. Loading won't alter the mechanical motion. It will alter the electrical behavior. If you draw any current the magnetic nonlinearities will get mixed in. Maybe the additional distortions are pleasant?

As for additional distortions, I only have one plot of HD for a transimpedance MM preamp. It's actually the lowest distortion I have seen for a cartridge, but apples to apples is really hard.

What we are trying to do is work out ways that, without the sort of budget Shure brothers used to have that we can get some answers.

I don’t want you to bad mouth Shure Brothers again Bill

George

I thought about high speed video, but it's still v tricky because deflections are so small.Naked eye or high speed camera? Interesting possibility for measurement.

LD

I don’t want you to bad mouth Shure Brothers again Bill

George

You are being too subtle for me on a saturday night, afraid that went completely over my head!

I'm not sure what is to be learned from measuring the cartridge inductance in parallel with a resistor that can't be determined with a simulation.

"Series-thru" impedance measurement, not shunt.

two more interesting data points. Sure once mentioned putting strain gauges in cantilevers (really painstaking if they actually did). Second data point- the strain gauge cartridge from Panasonic used the compliance of the pivot and the coupling to the stain elements as part of the equalization, or so they claimed when asked why the electronics were flat. There is no 500 Hz or 2.2 KHz bends in the electronics so they seemed to tune the rubber for that. If so the eq would change with temperature. One could try the same for a conventional cartridge to see if the suspension is affecting the response.

There is an app that takes film and then ‘amplifies’ movement. You have to shoot in 4K and you will need to be on a tripod, but the results are quite amazing based on the video I saw. Buildings rock alarmingly in in wind, speaker resonances etc

Might be one to look at for cantelever and arm resonances (someone told me pickup arms resonate at c 800 Hz - true or false?)

Here is the link:-

Video Magnification

Might be one to look at for cantelever and arm resonances (someone told me pickup arms resonate at c 800 Hz - true or false?)

Here is the link:-

Video Magnification

Last edited:

Would this Phono cartridge (Link) pick up (or detect) resonances and other anomalies you gentlemen are talking about ?

Regards.

There is still a cantilever suspension system to deal with, strain gauge carts have no "magnetics" either and still have problems but they have the additional problem of the mechanical interface to the strain sensing apparatus. So who knows?

A little too much fluff in the write up but it's interesting that they claim most turntables are "5" wired. It's pretty easy to run through the SNR and sensitivity numbers of PD systems especially if they are only intensity modulation.

Last edited:

Hmm, you could always take two identical cartridges and set one up as the "transmitter", the other the "receiver". Mbe use Guerilla Glue to attach the two stylii to each other...

We've been over this there is no evidence of any more than a tiny (if any) coupling. A MM/MI cart easily survives 100mV @ 100Hz applied to the motor with no evidence of even the slightest motion under a high power microscope.

Second data point- the strain gauge cartridge from Panasonic used the compliance of the pivot and the coupling to the stain elements as part of the equalization, or so they claimed when asked why the electronics were flat. There is no 500 Hz or 2.2 KHz bends in the electronics so they seemed to tune the rubber for that. If so the eq would change with temperature. One could try the same for a conventional cartridge to see if the suspension is affecting the response.

But the panasonic electronics were not flat. The Gary Galo article goes into this in depth. There is some rising response from the strain gauge so the expected 12.6dB of boost 500Hz-2kHz is not needed, more like 9dB. But the reality of the eq that panasonic included suggests the actual cartridge was all over the shop.

Kevinkr has discovered much the same.

Thanks, love it anyway.There is an app that takes film and then ‘amplifies’ movement. You have to shoot in 4K and you will need to be on a tripod, but the results are quite amazing based on the video I saw. Buildings rock alarmingly in in wind, speaker resonances etc

Might be one to look at for cantelever and arm resonances (someone told me pickup arms resonate at c 800 Hz - true or false?)

Here is the link:-

Video Magnification

You never know, it might be just brilliant. What one would need is a headshell or cartridge mounted camera with a microscope lens at high mag.

The normal warp and eccentricity would swamp any attempt by a tripod etc.

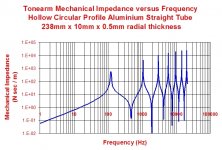

Edit: Yup, a few hundred Hz is about right for the lowest supported mode of a tonearm, but actually that's part of a series of resonances in the audioband working through the modes. Not a sign of it in the signal though...………

2nd edit: here's a blast from the past for tonearm resonances calculated impedance

LD

Attachments

Last edited:

Alex Korf measured resonance of a lot of different tonearms and tried to correlate the quality of the sound reproduction to the measured data.

Armtube Prototypes — Summary of Findings

Hans

Armtube Prototypes — Summary of Findings

Hans

oh yes. Forgot it still requires some physical connection to move cantilever and in addition a shading plate as they mention.There is still a cantilever suspension system to deal with,

-x-

one more noob question. How about this. these days we use digital recording to cut vinyl discs. Now if there is a test record needed to be cut (suppose a frequency sweep) we take source sweep digital files and subtract that from digital file recorded from typical MM phono cartridge turntable system. Whatever difference it shows can be evaluated for ex. electrical anomalies a MM+cantilever+coil+magnet would be having ??? I read that we can distinguish various components of digital audio with spectrum analyzer. LINK There may be some better advanced software too.

Regards

Whatever difference it shows can be evaluated for

Good but in there lies anything that is due to (master disk cut) + (transfer to stampers) + (vinyl pressing) + (vinyl playback) and you can not discriminate between all these.

George

Thanks, that all looks plausible. The sound of arms is about nuance, I think. IMO it doesn't show up as the 'mid dip' as sometimes claimed. It's a series of resonances that affects sound, but not in a way that is readily analysable using f sweeps, noise tracks etc.Alex Korf measured resonance of a lot of different tonearms and tried to correlate the quality of the sound reproduction to the measured data.

Armtube Prototypes — Summary of Findings

Hans

LD

Whilst sometimes Korf I believe misinterprets some things his measurements are very helpful. I wish I had time to repeat some of them. I'd love to measure my current in use arm, which is often scoffed at being a detachable headshell japanese S-shape, but at least with the one cartridge I have tried is producing beautiful music*, so much so that I am in no rush to swap back to my supposedly superior other table.

*No inference of accuracy is being made here, SWMBO and I are enjoying it. That is all

*No inference of accuracy is being made here, SWMBO and I are enjoying it. That is all

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Cartridge dynamic behaviour