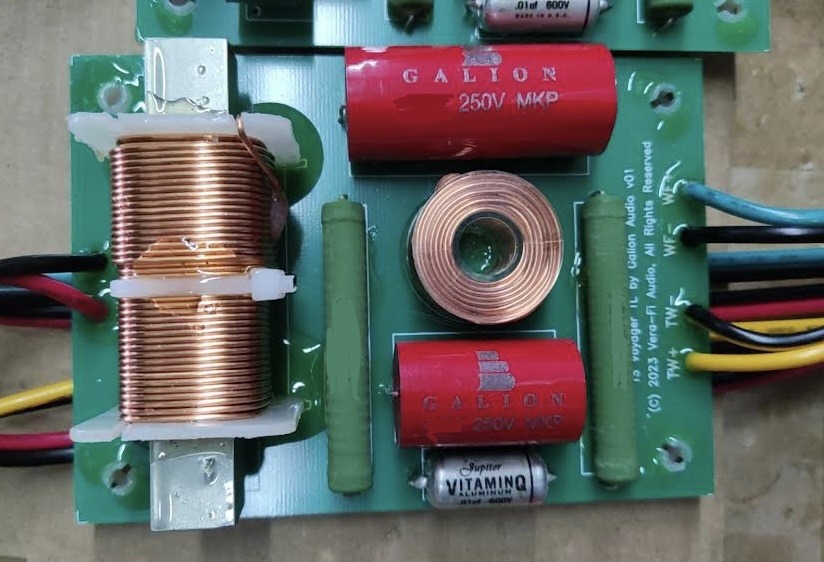

Just comparing the XO board and the binding post plates says a lot about the differences in quality.

Binding post cup on the Prodigy:

And I wonder if the Prodigy is birch plywood or MDF?

Binding post cup on the Prodigy:

And I wonder if the Prodigy is birch plywood or MDF?

I saw Thomas' post on YouTube and immediately thought "huh, looks like an x design"

Nice looking speakers! How do you like the SB? driver in comparison to the DC130?

Nice looking speakers! How do you like the SB? driver in comparison to the DC130?

Good to know! I'm guessing then that the switch was made primarily for cosmetic reasons?The SB13PFC25-8 is a great driver. I feel it has a really nice smooth midrange. Both are nice drivers. The bass on the DC130 has a little more grunt. But I tested the speakers side by side with both in AB test and it comes down to personal preferences.

https://www.youtube.com/post/UgkxEpIpFgh2nBOIVEwCJjBOIHDARkcU789I

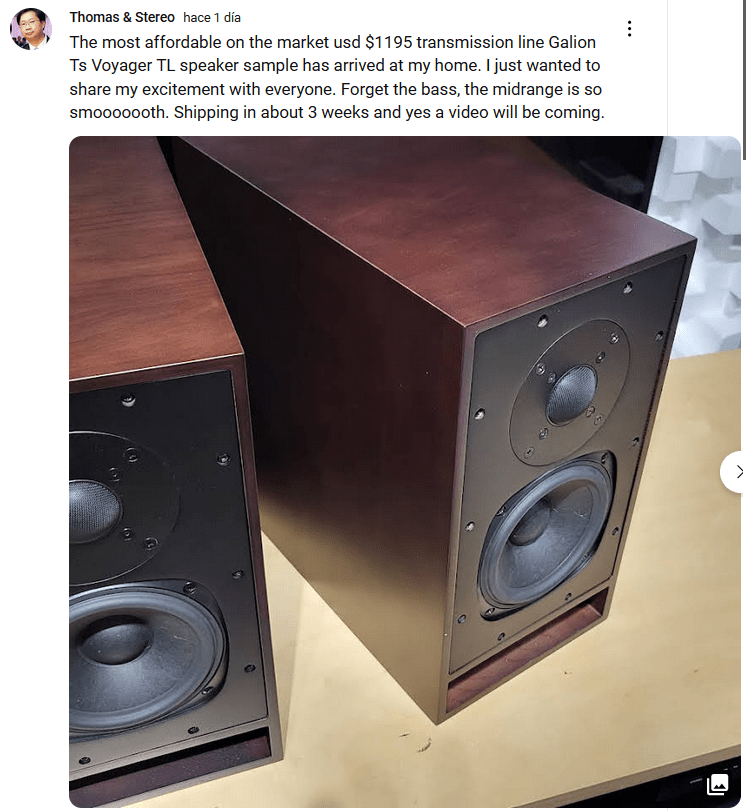

[ The most affordable on the market usd $1195 transmission line Galion Ts Voyager TL speaker sample has arrived at my home. I just wanted to share my excitement with everyone. Forget the bass, the midrange is so smooooooth. Shipping in about 3 weeks and yes a video will be coming. ]

[ The most affordable on the market usd $1195 transmission line Galion Ts Voyager TL speaker sample has arrived at my home. I just wanted to share my excitement with everyone. Forget the bass, the midrange is so smooooooth. Shipping in about 3 weeks and yes a video will be coming. ]

Hahah, people don’t like Philips screws! We will put hex drive bevel countersunk on tweeters and hex drive buttonhead on the woofers. I am looking forward to seeing Thomas’ review.

Philips screws are truly the worst that can happen to anyone who is interested of the insight 😉 if it's not for a retro replica these things are crap

Nearly all known Philips screws are weak produced stuff from China and even when used the right tool they are failing. I never had issues with a torx and comparable used force. For speakers it may be no issue but for me this type of screw is replaced every time I need to lay my hands on it. Just a pile of bad experiences

If it's a fully built speaker sent to the end user, I don't understand what all the fuss is about. I don't like Philips either, but for something like this I feel like it would be more the manufacturers' problem, not the buyer. Plus, if for whatever reason a buyer did want to mess with the screws, lots of people don't have torx drivers, so Philips might even be preferable

Of course you are right, it's up to the manufacturer to use whatever he likes. But this is a DIY forum and my opinion is only about the quality and trust issues due to problems I faced with these types.

Nowadays not everyone got torx at home...?

That's for me totally surprising. Maybe this is more a European thing but I really thought that it's an international standard. Is it not that common in the US?

Nowadays not everyone got torx at home...?

That's for me totally surprising. Maybe this is more a European thing but I really thought that it's an international standard. Is it not that common in the US?

I only got Torx drivers 2 years now. Hex drive is very prevalent though. I also like square head screw drive. It is less prone to stripping vs hex shape variants. I use that on baffle of many of my speakers. You can see it on the 10 screws for the baffle but still Philips on the drivers (easy to find part from Parts Express #6-3/4in wood screws in black oxide).

Okay, I hadn't been aware that it's so different and I'm sorry for using your thread for screw discussions.

All the drivers I'm buying are delivered with hex screws on some rare occasions even torx is provided.

I just had it once at importing speakers from parts express that Philips were used.

If done right in production and handling (!) you can of course use whatever screw type suits your tools or experience.

I don't know if this statement is correct but since the beginning of 2000 torx got more and more on the market and since 2010 it's popular on woodscrews and replaced nearly the PZ type.

The mentioned square heads I have never seen but I got the right bit for it in my Makita set.

All the drivers I'm buying are delivered with hex screws on some rare occasions even torx is provided.

I just had it once at importing speakers from parts express that Philips were used.

If done right in production and handling (!) you can of course use whatever screw type suits your tools or experience.

I don't know if this statement is correct but since the beginning of 2000 torx got more and more on the market and since 2010 it's popular on woodscrews and replaced nearly the PZ type.

The mentioned square heads I have never seen but I got the right bit for it in my Makita set.

I'm sure it's welcome 🙂 X brought it up after allOkay, I hadn't been aware that it's so different and I'm sorry for using your thread for screw discussions.

I didn't know that about Europe. You guys are ahead of the curve in that department. We find torx used in many of the products we buy, but most households don't carry torx drivers if I'm not mistaken. I remember a few years ago, I wanted to take my laptop apart, and before relenting and buying some myself, I asked all my friends if they had any I could borrow. None did!

The TS Voyager TL is undergoing testing in an anechoic chamber by Galion Audio. Thomas will be doing a video of his new speaker soon.

Jay raved about the speakers in part of his newest video

"He nailed it! Whoever designed this for Thomas, he just nailed it!"