Why do you want to do that? What improvement in sound do you expect?The loudspeakers cabinets from whatever they are put on.

yes, the "wobble" is eated by the material losses at a frequency that don't distub anything mechanically and the decoupling is necessary because the heavy cone subwoofer have enough energy to transfom my desktop into an emmisive surface...with a lot of harmonics.If you "decouple" the loudspeaker via a soft interface, the speaker is going to wobble... is that good?

So what is the purpose for your desired decoupling? To reduce transfered energy to not disturb the neighbours? Get rid of excited energy in the cabinet? If so why?

The only way to get rid of vibration is to turn it into heat.... best is to not start it to begin with.... i.e. its is only the entity that is suppose to vibrate that shall vibrate.. (read: speaker cone)

So?

The difference of sound between the damped and the undamped foots are abolutely shocking, you can come to hear if you want.

A spike don't decouple anything because most of these foots are not a real shpere/surface contact and the X/Y translations are blocked, this is technically impossible to fabric them properly because the spike penetrate the plane surface enough to be blocked.I would try to couple my cabinets to it via spikes or similar

Have you tried to push your loudspeakers cabinets, they should move, no ?

My baffle and its weight repartition is asmymetrical.For subwoofers I use SVS isolators. For floor standers I have placed the speaker on granite pavers which sit on rubber strips.

Last edited:

When you have a problem you need a solution, if there is no solution you must reduce the problem.Decoupling would be beneficial in those situations where loudspeaker vibration is transmitted through the floor and was creating some audible problem. But I think this is rare? yes? Most of the time, there is no vibrating floors and no audible problems. So a decoupling mechanism would unneeded complexity, at best... At worst, it could introduce other unforeseen problems.

Keep in mind that adding damping into such a system will serve to substantially increase the transmissibility of vibrations above the fundamental resonance frequency of the mass–spring system. A plot of transmissibility as a function of different levels of damping (c/cc) is shown below:To decouple, natural frequency of the (decoupling) system needs to be below the (loudspeaker) system frequency response, like at 10Hz or so, what ever. You can dampen it as well, if you wish.

Source: https://www.azom.com/article.aspx?ArticleID=23456

🦾Just figure out what's your spring constant and how much deflection needed to get the resonance that low with mass you have. If the spring becomes impossible, add mass. Then do a mechanical design that implements it. Now it's decoupled.

That really does depend on the amplitude of the "wobble".If you "decouple" the loudspeaker via a soft interface, the speaker is going to wobble... is that good?

By reducing the energy flow into the surrounding structure, the vibroacoustic output of the transmitted vibrations will be minimised.So what is the purpose for your desired decoupling? To reduce transfered energy to not disturb the neighbours?

The cabinet-wall vibrations will also cause acoustic output. The isolation system will have a very small effect on that. It would be feasible to glue constrained-layer damping pads to all the external surfaces of the loudspeaker enclosure, with the intention of reducing the cabinet-wall vibrations. The loudspeaker enclosures could become pieces of modern industrial art.Get rid of excited energy in the cabinet? If so why?

I'm not entirely sure of that. For example, having a large slab of concrete will enable the resonance frequency of the system to be made to be quite low. Think of the vibration isolation tables used in laboratories, particularly those involving optic experiments that are very sensitive to ground-borne vibrations.A clever desing is as light as possible, weight is totally useless and undesirable...

The above design is quite intriguing. It potentially offers a low vertical resonance frequency, which is desirable. The rubber component is there to introduce some viscoelastic damping, and it would need to be relatively soft, so as not to increase the stiffness too greatly (raising the resonance frequency). It would be interesting to see some measured vibration response data.I was thinking at a modern design, that works IRL.

View attachment 1468784

think of astronomyThink of the vibration isolation tables used in laboratories, particularly those involving optic experiments that are very sensitive to ground-borne vibrations.

Decoupling would be beneficial in those situations where loudspeaker vibration is transmitted through the floor and was creating some audible problem. But I think this is rare? yes?

Structure-borne sound from neighbours is a fairly common problem. Within the room the sound radiation from the very large area of the 6 room surfaces is subtantially louder. It's not a particularly intrusive form of unwanted sound within the room but effectively passively isolating a pair of large floorstanding speakers can bring a small audible improvement and a significant one to the neighbours.

If you "decouple" the loudspeaker via a soft interface, the speaker is going to wobble... is that good?

Wobbling at a few Hz will not be an audible problem but poor passive isolators with a resonant frequency at tens or hundreds of Hz (not uncommon with expensive audiophile accessories that play to the expectations of the nontechnical e.g. damping) might be because the vibration is amplified around the resonant frequency not reduced. Designing so that the softly sprung speaker doesn't topple is an issue though.

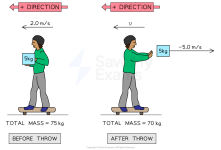

perhaps i don't understand the m1v1=m2v2, but i don't fear to explain things with simple words in order to be understanded by everyone and i don't know how adding mass can be a solution for a good decoupling.

And I like diagrams over words. More mass in the cabinet/woofer basket (m2) makes the cone (m1) move more (v1) and the cabinet/basket move less (v2). Good!

Attachments

Video of a tuned mass damper for a tall tower type object:

Subject matter starts at time 6:42

Heart of the subject starts at time 11:00

Subject matter starts at time 6:42

Heart of the subject starts at time 11:00

The feet arc shaped springs are deforming on all the axis, you will go nowhere without a CAD modelization and simulation of the entire system IMOAnd I like diagrams over words. More mass in the cabinet/woofer basket (m2) makes the cone (m1) move more (v1) and the cabinet/basket move less (v2). Good!

I've used a seismic application on my smartphone, calibrated the woofer on 30Hz at 90Bd(C) at 30cm and the application give me a seism of magnitude 3 when the smartphone on the cabinet and absolute zero when i put the smatphione on the desktop under the cabinet (between the feet).

I havent anything else to mesure but the desktop seems absolutely inert.

Last edited:

Mmmh just searched 'suspended speakers' and 'me' ( picowallspeaker) and...opened a can of worms! Ha haha

First, I found pics!!!

https://www.diyaudio.com/community/...ds-per-crossover-midrange-and-tweeter.420678/

And then, the same things repeated over and over...

https://www.diyaudio.com/community/...ds-per-crossover-midrange-and-tweeter.420678/

https://www.diyaudio.com/community/threads/5-way-ugly-swinging-dipole-build.343040/#post-5922801

First, I found pics!!!

https://www.diyaudio.com/community/...ds-per-crossover-midrange-and-tweeter.420678/

And then, the same things repeated over and over...

https://www.diyaudio.com/community/...ds-per-crossover-midrange-and-tweeter.420678/

https://www.diyaudio.com/community/threads/5-way-ugly-swinging-dipole-build.343040/#post-5922801

Well, I don't know how the 'how to wire an L-Pad ' went in place of the pics. The pics are in the last link - 5 way ugly suspended...- thread.

Funny that I 'm going to use that 'enclosure' again.

Funny that I 'm going to use that 'enclosure' again.

Cut four (assuming a stereo pair) pieces of MDF, drill a few blind holes around the edges at regular intervals (so they correspond with the holes in the other pieces) fit short coil springs in the holes nearest the corners, then fit a second piece of MDF on top so the springs fit in the holes, then sit the speaker on top, if it sags too much, add more springs in places to keep the speakers level. If they wobble too much, damp them by adding foam between the MDF boards.

Isn't it easier to make like this -pics, eventually-!??

All the "wires' are rubber-bands, just in case someone confuses them

https://www.diyaudio.com/community/threads/floating-speaker-enclosures.236880/page-2#post-3539827

All the "wires' are rubber-bands, just in case someone confuses them

https://www.diyaudio.com/community/threads/floating-speaker-enclosures.236880/page-2#post-3539827

It's an old question and many have considered it. Two competing problems: 1. you don't want the speaker to move around because the sound will be "smeared", i.e., Newton's law says the speaker will move in the opposite direction of the voice-coil/diaphragm, and 2. you don't want the floor to resonate possibly coloring the sound. So you have to choose your poison, if the speaker is isolated it will move around, or vibrate but If you couple it to the floor, then the floor may resonate.

A friend and colleague in the acoustic consulting world in the 1990s who specialized in post-production rooms for music recording studios introduced me to this dilemma. Back then post-production rooms where generally on floating slabs for sound isolation, 4" to 6" thick heavy-weight concrete over 2" rubber pads (and still are) with the room built on top of the floating slab. Typically a hardwood floor is installed over the floating slab. His solution was to support each speaker on a spring-isolated plinth, with the plinth typically filled with kiln-dried sand for both mass and to damp internal resonances. The speakers were then rigidly mounted to the top of the plinths. The steel spring isolators could easily be tuned to a 3-6 Hz natural frequency with the weight on top. So the speakers were well isolated from the floor but the speakers would move less, proportional to the weight of the plinth+speakers. The rooms I remember seeing this in were at Bertelsmann when they built their recording facility on an upper floor of 1540 Broadway in New York with B&W 801s mounted on such plinths (yes those B&Ws were in vogue at the time among post-production engineers, though it seems like a diffraction nightmare when I think about those stacked cubes now).

As Wright says, for those of us with more limited resources, I would say it depends how rigid your floor is. My floors are 6" concrete, so I'm not too worried about floor resonances, but those with wood joist floors might make a different decision. Also those adjacent to other apartments, or other rooms in the house might want isolators for the speakers. I like the inner tube idea, simple and adjustable. Also excellent isolation can be had by suspending speakers with bungee cords deflecting 2 inches or more (as long as decor is not an issue).

-Ben

.

A friend and colleague in the acoustic consulting world in the 1990s who specialized in post-production rooms for music recording studios introduced me to this dilemma. Back then post-production rooms where generally on floating slabs for sound isolation, 4" to 6" thick heavy-weight concrete over 2" rubber pads (and still are) with the room built on top of the floating slab. Typically a hardwood floor is installed over the floating slab. His solution was to support each speaker on a spring-isolated plinth, with the plinth typically filled with kiln-dried sand for both mass and to damp internal resonances. The speakers were then rigidly mounted to the top of the plinths. The steel spring isolators could easily be tuned to a 3-6 Hz natural frequency with the weight on top. So the speakers were well isolated from the floor but the speakers would move less, proportional to the weight of the plinth+speakers. The rooms I remember seeing this in were at Bertelsmann when they built their recording facility on an upper floor of 1540 Broadway in New York with B&W 801s mounted on such plinths (yes those B&Ws were in vogue at the time among post-production engineers, though it seems like a diffraction nightmare when I think about those stacked cubes now).

In my opinion, if I had a thick heavy floor, I would try to couple my cabinets to it via spikes or similar. If my floor was prone to vibration, I would attempt to decouple it. But exactly how best to do that without impacting my speaker drivers is still a question. I am not aware of an investigation that has shown this definitely as of yet

As Wright says, for those of us with more limited resources, I would say it depends how rigid your floor is. My floors are 6" concrete, so I'm not too worried about floor resonances, but those with wood joist floors might make a different decision. Also those adjacent to other apartments, or other rooms in the house might want isolators for the speakers. I like the inner tube idea, simple and adjustable. Also excellent isolation can be had by suspending speakers with bungee cords deflecting 2 inches or more (as long as decor is not an issue).

-Ben

.

If you isolate each speaker inside a system, bingo! **

Then you would want to isolate all the pieces that form a system, you crazy nerds.

You would then need a room to play with your thingies that make music.

** Useful to repeat: the tweeter detached from the midrange detached from the woofer

Then you would want to isolate all the pieces that form a system, you crazy nerds.

You would then need a room to play with your thingies that make music.

** Useful to repeat: the tweeter detached from the midrange detached from the woofer

- Home

- Loudspeakers

- Multi-Way

- What's the problem with modern proper loudspeaker cabinets decoupling?