Hi Demian,

Yes, I think you mentioned that earlier (see, I do read what you post!).

I don't need static free as I am pretty use to working with static sensitive equipment. All I need and want is a flat surface that is a little soft that stands up to a lot of wear. Being heat resistant is a huge bonus. It should be easy to clean solder flashing and drips, plus chemical spills from solvents and flux.

How are your mats standing up?

-Chris

Yes, I think you mentioned that earlier (see, I do read what you post!).

I don't need static free as I am pretty use to working with static sensitive equipment. All I need and want is a flat surface that is a little soft that stands up to a lot of wear. Being heat resistant is a huge bonus. It should be easy to clean solder flashing and drips, plus chemical spills from solvents and flux.

How are your mats standing up?

-Chris

The other downside of the silicone pads is that everything "sticks" to them. Fine dust, dirt shavings etc. get on the pads and won't dust off. Even wiping with alcohol doesn't work. Sometimes the vacuum won't get it off. Fortunately you can pick them up and brush or rinse them. The antistatic mats however have a smooth hard surface that does clean easily.

Hi Demian,

I could deal with that on the bench as there isn't a reason to staple or nail these mats down, unlike what I have been using. The anti-static mats sound like would be absolutely perfect. I'm looking for one for around $80 CA. It's 2 1/2' wide and 5' long.

-Chris

That is actually perfect for a turntable mat! I've been looking for something like this for a few years now.The other downside of the silicone pads is that everything "sticks" to them.

I could deal with that on the bench as there isn't a reason to staple or nail these mats down, unlike what I have been using. The anti-static mats sound like would be absolutely perfect. I'm looking for one for around $80 CA. It's 2 1/2' wide and 5' long.

-Chris

I hesitate to tell all you folks the secret to keeping a clean bench. When you bench gets all cluttered up, build a new one!

I am on my third. Each one is specialized and that helps to keep the clutter down. As I tell folks my shop is not that large, it is only half an acre. But it is heated and cooled.

One of my habits is to clean up before begining a project. Cleaning up after means everyone else's junk accumulates and gets in the way later.

I do spend a week or two every year cleaning, lubricating, checking calibration and repairing my tools. I do have voltage, frequency and sound pressure level standards. For those who don't understand a calibrator must be checked against a standard. Standards are compared to others by usually national labs.

Now voltage standards used to be a standard cell kept at a precise temperature. I have one of those, but it is not as good a semiconductor reference you can buy these days.

The frequency reference came out of a recycled cell phone site. The sound level piston phone was NASA surplus. It came with a barometer to do atmospheric pressure corrections.

Now I have mentioned before eBay reciprocity calibration! Buy three of the same item. If they all agree, then they are in calibration and resell the other two as in calibration. If they don't agree then don't buy them. (Apologies to Will Rogers.)

I am on my third. Each one is specialized and that helps to keep the clutter down. As I tell folks my shop is not that large, it is only half an acre. But it is heated and cooled.

One of my habits is to clean up before begining a project. Cleaning up after means everyone else's junk accumulates and gets in the way later.

I do spend a week or two every year cleaning, lubricating, checking calibration and repairing my tools. I do have voltage, frequency and sound pressure level standards. For those who don't understand a calibrator must be checked against a standard. Standards are compared to others by usually national labs.

Now voltage standards used to be a standard cell kept at a precise temperature. I have one of those, but it is not as good a semiconductor reference you can buy these days.

The frequency reference came out of a recycled cell phone site. The sound level piston phone was NASA surplus. It came with a barometer to do atmospheric pressure corrections.

Now I have mentioned before eBay reciprocity calibration! Buy three of the same item. If they all agree, then they are in calibration and resell the other two as in calibration. If they don't agree then don't buy them. (Apologies to Will Rogers.)

Hi Demian,

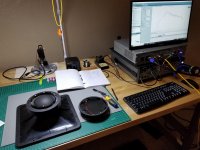

Yes, I am on my new bench. This is a sure fire way to start clean. I also take a few hours every few weeks to aggressively toss things I don't need. Like the parts that might be good. That's not good enough, these days I'm more in the habit of tossing them immediately.

Still cleaning out the basement after a decade (almost two) of collecting stuff again. The cutting is starting to hurt - a good sign that I'm doing damage to the pile.

-Chris

Yes, I am on my new bench. This is a sure fire way to start clean. I also take a few hours every few weeks to aggressively toss things I don't need. Like the parts that might be good. That's not good enough, these days I'm more in the habit of tossing them immediately.

Still cleaning out the basement after a decade (almost two) of collecting stuff again. The cutting is starting to hurt - a good sign that I'm doing damage to the pile.

-Chris

The amount of junk on my bench has grown over the years until I now have 9 inches by 9 inches to work in. I seem to get by OK. Despite everything being in random places on the bench I can always find what I want.

My rack of component draws isn't quite in order but I can still go straight to what I want.

100_0071 | KODAK Digital Still Camera | harrabylad | Flickr

My rack of component draws isn't quite in order but I can still go straight to what I want.

100_0071 | KODAK Digital Still Camera | harrabylad | Flickr

I usually have several projects running in parallel. They rarely share anything except the limited space and always have tight deadlines (or they would be in the queue). At one end is calibration of vintage instruments at the other is troubleshooting sota dsp headphones. And repairing the occasional lockset, laptop or toaster oven.

So the clutter is continuous and I just live with it. But I can deal with many different challenges pretty quickly. And cleanup some time in the far distant future.

So the clutter is continuous and I just live with it. But I can deal with many different challenges pretty quickly. And cleanup some time in the far distant future.

http://www.buildaudioamps.com/project-61

Moderator note: This link takes a long time to open, so leave the new window open until it loads

Moderator note: This link takes a long time to open, so leave the new window open until it loads

Last edited by a moderator:

I was gonna say that three Fluke 87’s was overkill, but then I noticed one is only an 85, so that’s okay then.

You can never have too many meters on your bench! The cost of batteries will keep you in check.

-Chris

-Chris

I’m starting the build on a second Frex LT AN67 oscillator. I already have one of these, which started life as a 10KHz unit, but which I modified to do 1KHz. I really want a good 10KHz source, and my own design switchable unit just isn’t playing the game, so Frex to the rescue.

I also have his RMS/LNA board, which will no doubt come in extremely useful.

To aid assembly, I’ve mounted an old 24” 2.5K monitor on an articulating arm on my bench, so I can set it up close enough to the microscope to read the doco without having to put my glasses on (I’m shortsighted, which is great for building boards as I see really good detail, but is a pain if I have to read stuff that’s a distance away). That’s connected to an old mac mini, that’s repurposed from its role as a media server.

It can still serve media, of course, so I’ve connected an amplifier and set of titchy speakers. Add in the glass of red and I’m all set.

I also have his RMS/LNA board, which will no doubt come in extremely useful.

To aid assembly, I’ve mounted an old 24” 2.5K monitor on an articulating arm on my bench, so I can set it up close enough to the microscope to read the doco without having to put my glasses on (I’m shortsighted, which is great for building boards as I see really good detail, but is a pain if I have to read stuff that’s a distance away). That’s connected to an old mac mini, that’s repurposed from its role as a media server.

It can still serve media, of course, so I’ve connected an amplifier and set of titchy speakers. Add in the glass of red and I’m all set.

Attachments

Hi Suzy,

Now there is a really nice setup! Clean and neat, I wish my clutter was under control but I fear its just me.

For refreshments I would change out the wine for a nice Scotch blend sipper. My favorite is a blend of Scotch and honey.

That new Frex board should really work out well for you too. Let us know how it goes.

-Chris

Now there is a really nice setup! Clean and neat, I wish my clutter was under control but I fear its just me.

For refreshments I would change out the wine for a nice Scotch blend sipper. My favorite is a blend of Scotch and honey.

That new Frex board should really work out well for you too. Let us know how it goes.

-Chris

Hi Suzy and all,

I like your old rotary phone the best, okay the microscope and everything else too 🙂

Just put an old black dial phone, to use again in the loft. I am getting to old to down 19 steps to get to the present one in time.

I too could use a couple of Frex oscillators, and a distortion magnifier, so I will follow along with your builds. I'll have to visit his thread again.

Decided on Frex vs Victors osc version, why may I ask?

Getting summer here, will have to wait til the snow blows again, I have garage/loft construction work instead.

cheers to myopic eyes for smt work

Rick

P.S. be very careful, that wine glass is in direct line with the soldering iron.

Chris,

Scotch goes good with Nakamichi too. need one for sure after repairing a old tape machine.

I like your old rotary phone the best, okay the microscope and everything else too 🙂

Just put an old black dial phone, to use again in the loft. I am getting to old to down 19 steps to get to the present one in time.

I too could use a couple of Frex oscillators, and a distortion magnifier, so I will follow along with your builds. I'll have to visit his thread again.

Decided on Frex vs Victors osc version, why may I ask?

Getting summer here, will have to wait til the snow blows again, I have garage/loft construction work instead.

cheers to myopic eyes for smt work

Rick

P.S. be very careful, that wine glass is in direct line with the soldering iron.

Chris,

Scotch goes good with Nakamichi too. need one for sure after repairing a old tape machine.

Last edited:

Hi Rick,

I might be getting a set of cassette test tapes. I have a tension tape coming so I can work on those things again. I must be a sucker for punishment!

Just did a CR-5 for myself. It was a great score and I'm really happy with it. I have a BX-300 as well that needs rubber parts.

-Chris

I might be getting a set of cassette test tapes. I have a tension tape coming so I can work on those things again. I must be a sucker for punishment!

Just did a CR-5 for myself. It was a great score and I'm really happy with it. I have a BX-300 as well that needs rubber parts.

-Chris

Hi vuohi,

That's a really neat setup!

Thank you.

Looks like you do a lot of smt parts.

-Chris

Actually not really. I made my first PCB with SMD parts only a few weeks ago, and even that was mostly through hole components. I've repaired some devices with SMD components and I have to say I'm not loving it.

Most of the time I deal with things that go "tick tock", usually without the "kaboom". Electronics is just a hobby.

- Home

- Design & Build

- Equipment & Tools

- What's on your workbench???