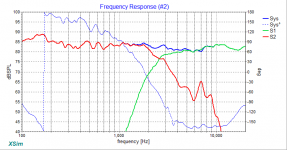

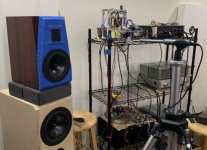

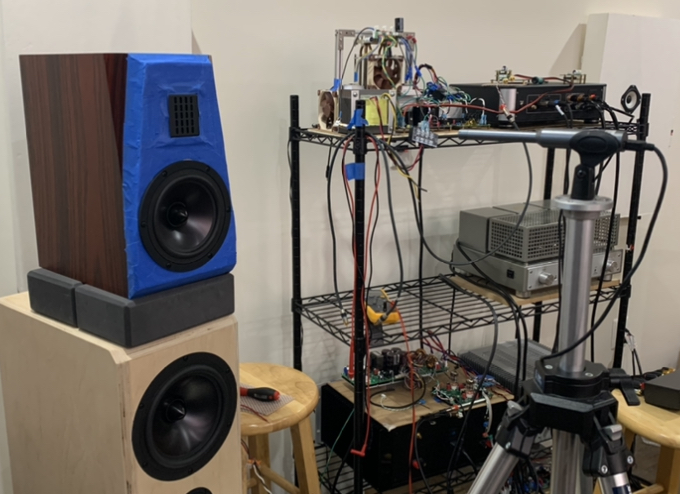

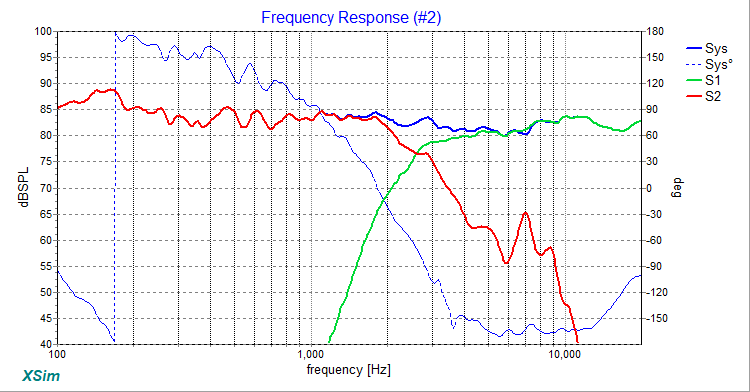

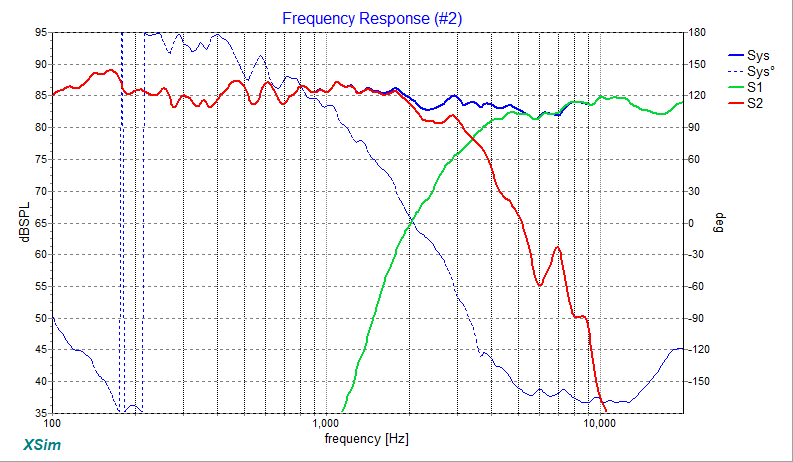

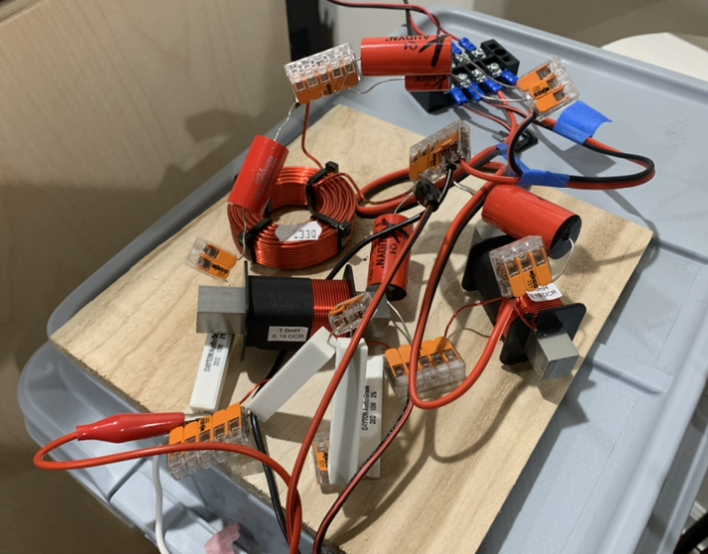

On the bench tonight Aug 15, 2021 is developing a new XO for a speaker. Planar GRS 3in tweeter and RS180-8 woofer. Measurements and simulation so far. I might get a chance to make a prototype XO using Wago connectors.

Attachments

Nice use of yoga bricks 😀

That Manfrotto is a rock: mine is like new after 20 years of hard work!

DIY is a lifestyle 😀 😀

That Manfrotto is a rock: mine is like new after 20 years of hard work!

DIY is a lifestyle 😀 😀

Nice! Are u still going to develop the RS225-8 and GRS planar?

Yes, it is next. This GRS 3in planar with the RS180 sounds pretty fantastic. I’m listening to it right now and the tonal balance is spot on. Nice upper extension with the planar while not sounding at all fatiguing. It’s voiced perfectly.

@peppennino: you have good eyes. Those yoga bricks are perfect for desktop speaker mounts for near field monitors (like my Rockvilles). I figured $7ea is way cheaper than similar $40 ones made of same EVA but sold for speakers. I had to really get this speaker high off the floor to avoid a floor bounce dip.

I have also had my Manfrotto 3021 for 21 years! Yes, it still works like new.

Attachments

Last edited:

Received some LuFo-Lite boards from a secret admirer tonight. 😉 Planning to jump back on that build shortly.

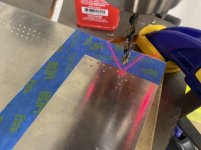

On the bench tonight. Lots O Drilling. Custom mono-block parts. I have just a few more holes to drill. 😀

On the bench tonight. Lots O Drilling. Custom mono-block parts. I have just a few more holes to drill. 😀

Attachments

You have laser guide marks on your drill press!? Cool.

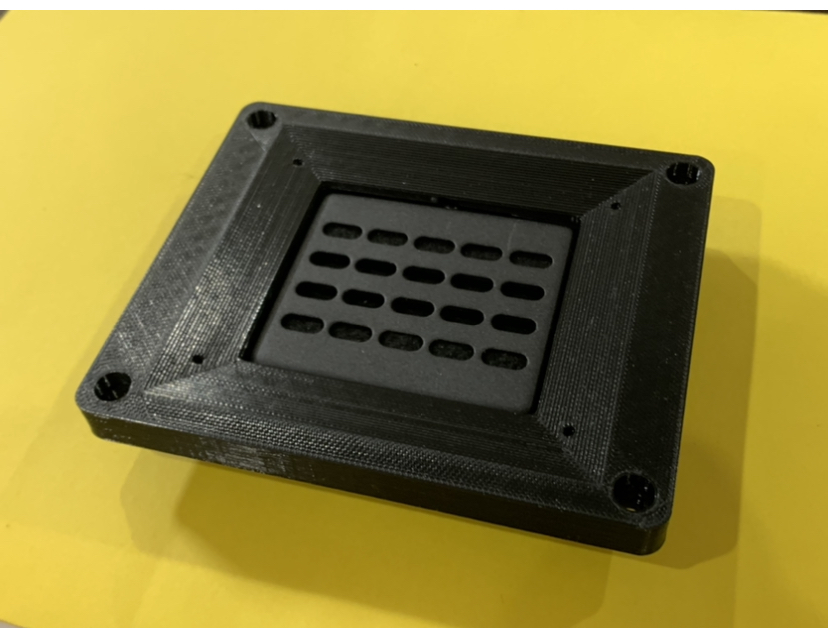

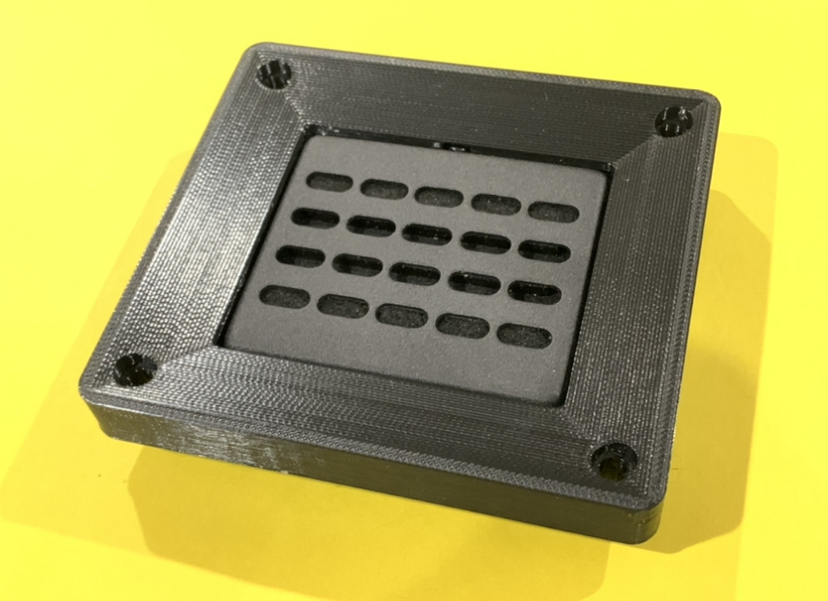

On the bench last night was CAD work for a new design for a waveguide and mounting bezel for the planar tweeter. It sounds great but the mech design literally has no way to mount it properly.

This is first cut rough to check fit. I’ll have to make a bit smaller. It’s a lot bigger when you see it in real life.

On the bench last night was CAD work for a new design for a waveguide and mounting bezel for the planar tweeter. It sounds great but the mech design literally has no way to mount it properly.

This is first cut rough to check fit. I’ll have to make a bit smaller. It’s a lot bigger when you see it in real life.

Attachments

Yep! Makes finding the bit center so easy. It’s a WEN 4225 I got a couple years ago. I fit a nice keyless chuck on it. All in all, great value for the money.

Pretty good resolution on your 3D printed waveguide X. What printer are you using?

Pretty good resolution on your 3D printed waveguide X. What printer are you using?

Dremel 3D45 - it’s only on medium resolution (0.2mm) at present with PLA. It can go to fine (0.1mm) and ABS makes a superior finish compared to this. The printer is very reliable. About as plug and play as there is as most 3D printers are very “DIY” and require futzing.

It’s on the skinnier side of platforms. The width and height are great but depth front to back is smaller than usual. I have an older one that’s bigger and size for a larger waveguide. But the thing is finicky to use and actually the hot end got clogged and I never managed to get it repaired. So it’s been out for 4 years now. 🙂

The Dremel is a pleasure to use. Printers have come a long way in usability. This one has very few settings to mess up. It has special filament with RFID so you always get consistent prints. The filament costs more though. Sort of the inkjet printer analogy.

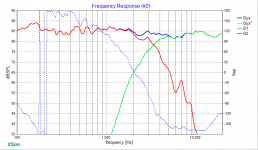

Latest update to my speaker XO now at 3.5kHz. Sounding really good.

The Dremel is a pleasure to use. Printers have come a long way in usability. This one has very few settings to mess up. It has special filament with RFID so you always get consistent prints. The filament costs more though. Sort of the inkjet printer analogy.

Latest update to my speaker XO now at 3.5kHz. Sounding really good.

Attachments

Last edited:

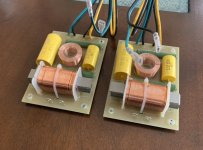

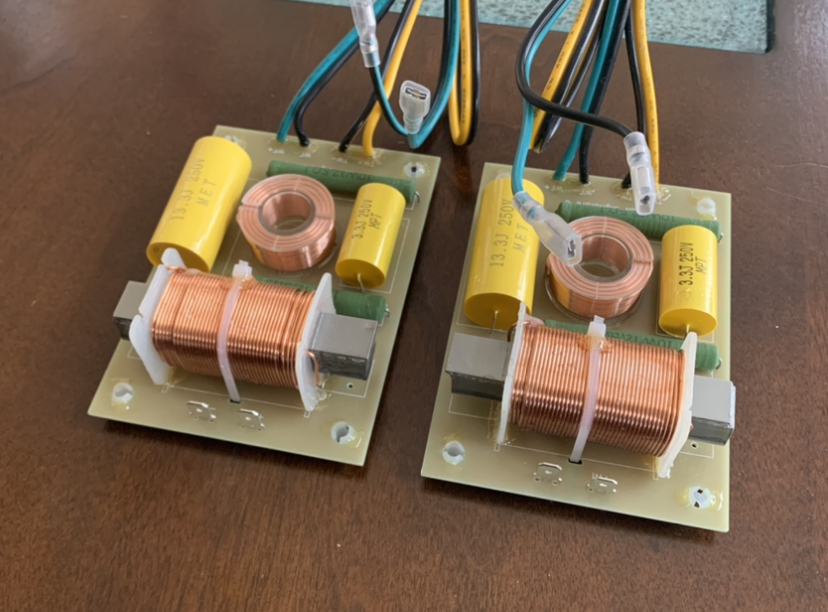

These crazy “Wago XO’s” eventually become neat and tidy custom crossovers like these samples that just arrived from the manufacturer- these will go into a new commercial speaker that I designed recently for LSA.

All the components are made to order - exact values. Have you ever seen a 13.3uF film cap? 😀

All the components are made to order - exact values. Have you ever seen a 13.3uF film cap? 😀

Attachments

Thanks, Jwjarch! I am upgrading the 13.3uF cap to MKP in the production version. It’s a nice crossover and amazingly compact for what it is vs a hand P2P job.

I revised the waveguide to be much more compact. This looks a lot better and has smaller CTC distance to the woofer. I nailed the fit on this one. No Dremel tool post print cleanup work needed. 🙂

I revised the waveguide to be much more compact. This looks a lot better and has smaller CTC distance to the woofer. I nailed the fit on this one. No Dremel tool post print cleanup work needed. 🙂

Attachments

Last edited:

I’ll post the link when they are available for ordering through LSA. They do sound very very good. I would post a YouTube link but it always gets blocked for copyright. I have no idea how other people manage to post recordings of speakers playing music.

I’ll post the link when they are available for ordering through LSA. They do sound very very good. I would post a YouTube link but it always gets blocked for copyright. I have no idea how other people manage to post recordings of speakers playing music.

You can try bit chute instead. This copyright issue is totally annoying indeed …

A fanatic, extremist, perfectionist would stain or paint the inside of speaker cabinet. The diyer got the time and he is OCD. Nothing wrong with that.

Painting inside of a speaker cabinet

Painting inside of a speaker cabinet

More discussion on painting inside enclosure. Gotta protect the speaker even if unnecessary. But no harm no foul. So why not?

Paint the inside of the speaker cabinet? -

Techtalk Speaker Building, Audio, Video Discussion Forum

Paint the inside of the speaker cabinet? -

Techtalk Speaker Building, Audio, Video Discussion Forum

For the next project,for the guy who knows what he is doing (that is not me) Diy with time to spare an illustrated build guide and video on youtube.

I think it’s good to leave one side unfinished to let the wood breathe. Coming from someone who leaves most of his cabinets bare wood I guess it doesn’t mean much. Some wood like carbonized bamboo has been treated with basically a sealer that’s like plastic you don’t even need to finish it. Just sand it smooth and buff it.

These are my Rockville’s made from bamboo.

These are my Rockville’s made from bamboo.

Attachments

Last edited: