Hey Frank, you got some pretty good charts for iron.

Any Grain Oriented M6 iron charts?

I would be interested on those.

Any Grain Oriented M6 iron charts?

I would be interested on those.

CHARTS.

Hi,

Would coffee bean oriented ones do?

Cheers,😉

Hi,

Any Grain Oriented M6 iron charts?

Would coffee bean oriented ones do?

Cheers,😉

Coffee beans

Still on the learnig curve on how to persuade you.

Maybe Jam could give some advise!!!

Would coffee bean oriented ones do?

[/B]

Still on the learnig curve on how to persuade you.

Maybe Jam could give some advise!!!

Okay guys, last week we put forth four parameters that effect the selection of a good audio power transformer and since there has been no input that has changed the last edited list version:

1. core flux density (lower is better)

2. dc tolerance (higher is better)

3. wire thickness (thicker is better or application specific)

4. quiescent current (application specific or lower is better)

If anyone has anything else to add to this list concerning the selection of the main power transformer, please do so now. If we are done, we can move on to the next step in our analysis; defining the auditory characteristic of each parameter.

1. core flux density (lower is better)

2. dc tolerance (higher is better)

3. wire thickness (thicker is better or application specific)

4. quiescent current (application specific or lower is better)

If anyone has anything else to add to this list concerning the selection of the main power transformer, please do so now. If we are done, we can move on to the next step in our analysis; defining the auditory characteristic of each parameter.

TRICKY BUSINESS.

Hi,

Thicker wire is not going to cut it, it will change the stray capacitance amongst other things.

Don't tell Gina...😉

Hi,

3. wire thickness (thicker is better or application specific)

Thicker wire is not going to cut it, it will change the stray capacitance amongst other things.

Don't tell Gina...😉

fdegrove

We have contradictory reports on the issue of the wire thickness. It has been proposed that a thinner wire will create a sort of "smoothing" effect but it has also been documented that using a thinner wire results in an overworked transformer, which is also detrimental to sound. Perhaps until we pinpoint its effects we should modify this parameter to application specific. I'm glad that you have had chance to reflect on your initial opinion. On another note, if I start concerning myself with the preferences and activities of our mutual friend, I would surely be consumed. She is very much like like the sun, very enjoyable from a safe distance but much too hot to get to close to. Are we agreed to start here?

1. core flux density (lower is better)

2. DC tolerance (higher is better)

3. quiescent current (lower is better or application specific)

4. wire thickness (application specific)

Later today, we will begin looking over each parameter in greater detail and after that we will begin examining interactivity with the whole power supply. As you can imagin, this is going to take awhile.

We have contradictory reports on the issue of the wire thickness. It has been proposed that a thinner wire will create a sort of "smoothing" effect but it has also been documented that using a thinner wire results in an overworked transformer, which is also detrimental to sound. Perhaps until we pinpoint its effects we should modify this parameter to application specific. I'm glad that you have had chance to reflect on your initial opinion. On another note, if I start concerning myself with the preferences and activities of our mutual friend, I would surely be consumed. She is very much like like the sun, very enjoyable from a safe distance but much too hot to get to close to. Are we agreed to start here?

1. core flux density (lower is better)

2. DC tolerance (higher is better)

3. quiescent current (lower is better or application specific)

4. wire thickness (application specific)

Later today, we will begin looking over each parameter in greater detail and after that we will begin examining interactivity with the whole power supply. As you can imagin, this is going to take awhile.

Thick wire...or "shaped" ?

Thinking of those "flat" wire inductors...probably not useful for a trafo?

And the dielectric for the trafo-wire...what about something better / thicker than the thin isolating layer they usually have...?

Arne K

Thinking of those "flat" wire inductors...probably not useful for a trafo?

And the dielectric for the trafo-wire...what about something better / thicker than the thin isolating layer they usually have...?

Arne K

nania said:

1. core flux density (lower is better)

2. DC tolerance (higher is better)

3. quiescent current (lower is better or application specific)

4. wire thickness (application specific)

Each time you change any detail on a trafo design you will be changing the overall parameters of the trafo. So when you say that you want a lower core flux you will have to increase the size or weight of the iron to mantain the same power and by doing that you will get better regulation (efficiency).

But also by doing so you will have a longer coil wire which means more DCR and stray inductance and more interwinding capacitance and more temperature to disipate.

And by doing so you go back and try to compensate changing to a bigger wire and you run in to trouble on window filling.....etc etc.

So at the end you understand there is only so much that can be done so you have to set constraints and priorities to get a balanced design.

Of course commercialy available trafor most likely will have a high flux density to try to get the most out of the iron but if they go overboard you will have a noisy trafo, bad regulation, heat and so on.

IMO a well designed trafo will need to have a good core material (say something like M15, maybe not better since you fall into other problems) which will support a high flux density and set your design at some 75 to 80 % of that. That will give you a balanced size for the iron.

Second, you will need to fill the window (speaking of EI trafos) as much as possible with copper, around 50% for each primary and secondary. A good PSU trafo will also have at least 5 winding sections (three primary and two secondaries) to reduced capacitance and have low stray inductance (good coupling between primary and secondary).

It's dificult to set parameters on trafors since it will depend of factors such as core material and type, power and application. This is, smaller (lower power) trafos will usally have better spec than bigger ones (both well design).

WALKING THE TIGHT ROPE.

Hi,

Well said, Tony.

It is indeed a balancing act where the designer has to factor in many parameters.

On my priority list I would put good regulation high, heat is an indication that the xformer is working too hard and not really efficient, in those cases the secondary wire gauge may be too thin with respect to the current demands.

Indeed, this is a typical case of 'Horses for courses".

Ubdersrtanding what xformer does and what you want from it for the application at hand is a key factor here.

Cheers,😉

Hi,

Well said, Tony.

It is indeed a balancing act where the designer has to factor in many parameters.

On my priority list I would put good regulation high, heat is an indication that the xformer is working too hard and not really efficient, in those cases the secondary wire gauge may be too thin with respect to the current demands.

It's dificult to set parameters on trafors since it will depend of factors such as core material and type, power and application. This is, smaller (lower power) trafos will usally have better spec than bigger ones (both well design).

Indeed, this is a typical case of 'Horses for courses".

Ubdersrtanding what xformer does and what you want from it for the application at hand is a key factor here.

Cheers,😉

apassgear

fdegrove

Yes, but that doesn't invalidate our method. If we compare two identically rated transformers, the parameters we are focusing upon should factor in to our audio result, agreed? The point of this whole excercise is to see what does what.Each time you change any detail on a trafo design you will be changing the overall parameters of the trafo.

fdegrove

Please be more specific: Are you saying that regulation should be in its own category or is it a derivative function of the four parameters that we have already identified? Describe exactly what you mean by "regulation"On my priority list I would put good regulation high, heat is an indication that the xformer is working too hard and not really efficient, in those cases the secondary wire gauge may be too thin with respect to the current demands.

ABOUT REGULATION.

Hi,

Regarding regulation:

There are two kinds:

Load regulation and line regulation.

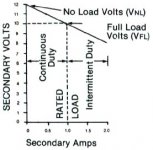

Load regulation example:

The transformer output is generally rated at continuous full load (Eg. 10 volts @ 1.0 AMP). Lighter loads will result in higher output voltages (Eg. 11 volts @ 0.5 AMP). Heavier or intermittent loads will result in proportionally lower voltage dips (Eg. 9 volts @ 1.5 AMP). Larger transformers have better load regulation than smaller transformers. Typically, 500VA = 5%; 100VA = 10%; 50VA = 15%; 10VA = 20%; 5VA = 30%.

Line regulation example:

A 120V fluctuating +/- 10% (108V to 132V) would cause a 10 volt rated secondary to fluctuate +/- 10% (9V to 11V). The no load voltage would respond similarly with the 12V becoming +/- 10% (10.8V to 13.2V).

Cheers,😉

Hi,

Regarding regulation:

There are two kinds:

Load regulation and line regulation.

Load regulation example:

The transformer output is generally rated at continuous full load (Eg. 10 volts @ 1.0 AMP). Lighter loads will result in higher output voltages (Eg. 11 volts @ 0.5 AMP). Heavier or intermittent loads will result in proportionally lower voltage dips (Eg. 9 volts @ 1.5 AMP). Larger transformers have better load regulation than smaller transformers. Typically, 500VA = 5%; 100VA = 10%; 50VA = 15%; 10VA = 20%; 5VA = 30%.

Line regulation example:

A 120V fluctuating +/- 10% (108V to 132V) would cause a 10 volt rated secondary to fluctuate +/- 10% (9V to 11V). The no load voltage would respond similarly with the 12V becoming +/- 10% (10.8V to 13.2V).

Cheers,😉

Attachments

Regulation, as said, is a function of the design parameters. And power "Raiting" is set by the manufacturer following commercial issues and what they can get away with.

Say a trafo is rated at 100VA but its working at 90% of the max core flux so you will see that it does not have good regulation since it working almost to saturation and will not have any headroom say a 10% overcapacity on peak demands will through it well in to saturation. On this (extream) situation you can expect a lousy regulation.

So coming back to core materials. I would put this issue way up con the selection of trafos. Meaning that a good material will be way better, even in a smaller size and weight than a bigger with lesser core material. This is, a good core material will have a high core flux saturation value plus a proportionaly much lower core losses. Provided that both designs are "good".

So bigger it's not always better even though it implies better regulation but does not take in consideration core and winding losses.

Of course non of these parameters are part of specifications by the manufacturer, so it is very dificult to make a selection. That's why we tend to select trafos form known good brands? I guess so.

As nania says low core flux is something good to have, but that is not the whole story. Since to be good it needs to be acompanied with a high core saturation value (this are all relative terms).

So for good regulation we would need:

1. Low core flux relative to core saturation value.

2. Low core and winding losses

Say a trafo is rated at 100VA but its working at 90% of the max core flux so you will see that it does not have good regulation since it working almost to saturation and will not have any headroom say a 10% overcapacity on peak demands will through it well in to saturation. On this (extream) situation you can expect a lousy regulation.

So coming back to core materials. I would put this issue way up con the selection of trafos. Meaning that a good material will be way better, even in a smaller size and weight than a bigger with lesser core material. This is, a good core material will have a high core flux saturation value plus a proportionaly much lower core losses. Provided that both designs are "good".

So bigger it's not always better even though it implies better regulation but does not take in consideration core and winding losses.

Of course non of these parameters are part of specifications by the manufacturer, so it is very dificult to make a selection. That's why we tend to select trafos form known good brands? I guess so.

As nania says low core flux is something good to have, but that is not the whole story. Since to be good it needs to be acompanied with a high core saturation value (this are all relative terms).

So for good regulation we would need:

1. Low core flux relative to core saturation value.

2. Low core and winding losses

Alright, since we are all in agreement that low core flux density is desirable, I think we can begin looking at the core flux issues in greater detail. We will identify the ways to achieve low core flux as lower case alphabetic characters so that:

1a. core size (bigger is better)

1b. core material (better saturation curve)

1c. windings (more turns are better)

1d. transformers in series

Please feel free to add or modify the list above. We will return to the issue of regulation after we determine its relation to the primary four issues that started this thread. Once this list is complete, we will begin to examine how flux density becomes detrimental to the sound of our amps.

1a. core size (bigger is better)

1b. core material (better saturation curve)

1c. windings (more turns are better)

1d. transformers in series

Please feel free to add or modify the list above. We will return to the issue of regulation after we determine its relation to the primary four issues that started this thread. Once this list is complete, we will begin to examine how flux density becomes detrimental to the sound of our amps.

fomer views

First off the name of the thread should be what makes a good audio power transformer. I think I might have been the one to start discussions on core saturation. most of this discussion is kind of futile because unless you are going to custom design a transformer you will have no say over most of these factors. If you did actually know what you wanted, getting a typical transformer shop to build it like you wanted is a major challenge. Exotic core material? How many hundred of these are you going to build? Really what you realistically have a choice about is running a transformer that will not reach core saturation. Putting dual primaries windings in series and selecting double the secondary voltage for the transformer since it will now be half that value with the primaries that are usually wired in parallel are in series. Selecting a much larger transformer VA rating than the load requirement will also help avoid saturation. There has been way to much emphasis on regulation. It is not that important for anything but power amps. Line level circuits like preamps are a fairly constant draw and are not going to put a stain of a sufficiently large transformer. Low winding resistance promotes larger peak diode currents and more EMI and possible saturation of the core. I often use a series resistor to limit the peak diode currents despite the decrease in regulation.

Well coupled windings for low leakage inductance increase the interwinding capacitance and allows more noise from the AC line to enter the supply. Split bobbin transformers minimize this coupling capacitance at the expense of great leakage inductance with no ill effects that I am aware of. Good luck finding data on the magnetic characteristics of transformer steel. I can routinely find data for ferrites and even computer simulation models but not much on steel on the web or the transformer text I have read thus far. I would read some of links mentioned in this thread on this stuff at the transformer manufactures site. There is enough stuff on the Plitron site to make you head spin. Remember most power transformers are designed for the biggest VA rating per cost and weight of materials. Go do some reading. I think this "4 Simple Rules For Rating my Transformer Wattage " show is getting you nowhere.

Below: Two transformer designers discuss the effect of DC voltage on core saturation.

apassgear said:Regulation, as said, is a function of the design parameters. And power "Raiting" is set by the manufacturer following commercial issues and what they can get away with.

Say a trafo is rated at 100VA but its working at 90% of the max core flux so you will see that it does not have good regulation since it working almost to saturation and will not have any headroom say a 10% overcapacity on peak demands will through it well in to saturation. On this (extream) situation you can expect a lousy regulation.

So coming back to core materials. I would put this issue way up con the selection of trafos. Meaning that a good material will be way better, even in a smaller size and weight than a bigger with lesser core material. This is, a good core material will have a high core flux saturation value plus a proportionaly much lower core losses. Provided that both designs are "good".

So bigger it's not always better even though it implies better regulation but does not take in consideration core and winding losses.

Of course non of these parameters are part of specifications by the manufacturer, so it is very dificult to make a selection. That's why we tend to select trafos form known good brands? I guess so.

As nania says low core flux is something good to have, but that is not the whole story. Since to be good it needs to be acompanied with a high core saturation value (this are all relative terms).

So for good regulation we would need:

1. Low core flux relative to core saturation value.

2. Low core and winding losses

First off the name of the thread should be what makes a good audio power transformer. I think I might have been the one to start discussions on core saturation. most of this discussion is kind of futile because unless you are going to custom design a transformer you will have no say over most of these factors. If you did actually know what you wanted, getting a typical transformer shop to build it like you wanted is a major challenge. Exotic core material? How many hundred of these are you going to build? Really what you realistically have a choice about is running a transformer that will not reach core saturation. Putting dual primaries windings in series and selecting double the secondary voltage for the transformer since it will now be half that value with the primaries that are usually wired in parallel are in series. Selecting a much larger transformer VA rating than the load requirement will also help avoid saturation. There has been way to much emphasis on regulation. It is not that important for anything but power amps. Line level circuits like preamps are a fairly constant draw and are not going to put a stain of a sufficiently large transformer. Low winding resistance promotes larger peak diode currents and more EMI and possible saturation of the core. I often use a series resistor to limit the peak diode currents despite the decrease in regulation.

Well coupled windings for low leakage inductance increase the interwinding capacitance and allows more noise from the AC line to enter the supply. Split bobbin transformers minimize this coupling capacitance at the expense of great leakage inductance with no ill effects that I am aware of. Good luck finding data on the magnetic characteristics of transformer steel. I can routinely find data for ferrites and even computer simulation models but not much on steel on the web or the transformer text I have read thus far. I would read some of links mentioned in this thread on this stuff at the transformer manufactures site. There is enough stuff on the Plitron site to make you head spin. Remember most power transformers are designed for the biggest VA rating per cost and weight of materials. Go do some reading. I think this "4 Simple Rules For Rating my Transformer Wattage " show is getting you nowhere.

Below: Two transformer designers discuss the effect of DC voltage on core saturation.

Attachments

Fred Dieckmann

We will eventually address the practicality of the parameters discussed in this thread and you should note that what is exotic and impractical today may not be so tomorrow. I happen to believe that the transformer manufacturers are referencing this thread for ideas so let's not thread crap.If you did actually know what you wanted, getting a typical transformer shop to build it like you wanted is a major challenge. Exotic core material? How many hundred of these are you going to build?

I disagree, and rather than try to kill a budding thread with your pessimism you should be looking forward to the answers that may come from it. Even if you have all your answers, I'm sure that many of the other membership finds merit in this examination. If you disagreed with the four aforementioned main areas of examination you were more than welcome to reorder the list, add to it or provide alternates without being cryptic. We are just beginning this journey and I doubt you or anyone else here finds the issues discussed "Simple" but my attempt is to find out what does what and that will enable the builders to make the best possible decisions based on what is available in the market now or in the future. I will concur that this thread could be renamed to reflect that we are talking about power transformers but I since we will be examining the effects of all these issues in detail, what we learn may very well apply to design decisions of other transformer applications as well. I leave it to the moderators to decide if the title should be changed.I think this "4 Simple Rules For Rating my Transformer Wattage " show is getting you nowhere.

simple is as simple does

You have reordered the priorities several times already. I doubt any transformer designers are reading this. Understanding some fundamental would be nice before attempting to advance the state of the art in future transformer design. has anybody read any of links on transformers in this thread. I would think that most people would want to know what they can do now. Advice that would allow one to use combinations of surplus transformers and nonstandard applications of off the shelf. I will stay out of it if you let you go back to the shuffling the 4 basic rules. I wonder why people thing design choices are so easy and cut and dried. Wishful thinking and a lack of willingness to do even the most basic research seems to be the order of the day. I will leave you in more capable hands but don't confuse motion with progress.

P.S. I am not a pessimist, merely pragmatic. I'm am sorry that you feel I have not contributed anything.

You have reordered the priorities several times already. I doubt any transformer designers are reading this. Understanding some fundamental would be nice before attempting to advance the state of the art in future transformer design. has anybody read any of links on transformers in this thread. I would think that most people would want to know what they can do now. Advice that would allow one to use combinations of surplus transformers and nonstandard applications of off the shelf. I will stay out of it if you let you go back to the shuffling the 4 basic rules. I wonder why people thing design choices are so easy and cut and dried. Wishful thinking and a lack of willingness to do even the most basic research seems to be the order of the day. I will leave you in more capable hands but don't confuse motion with progress.

P.S. I am not a pessimist, merely pragmatic. I'm am sorry that you feel I have not contributed anything.

Fred Dieckmann

Fred, we appreciate the links you provide and we do read them but what is behind the numbers is just as important. Honestly, I feel the question needs an answer: What exactly are you trying to discourage? Are you afraid of losing your ambiguous position as an authority on this forum? No one doubts you are well read. Some who have read this thread may doubt your work ethic and your ability to work in a group since your posts here have been curt and for the most part, not very specific. Even more will doubt your ability to do anything groundbreaking because of the record you have shown time and time again to be inflexable in your convictions and your belief that your way is the only way to enlightenment. I understand you very well and pity you as much as I admire you. I hope that unlike King Lear you will 'grow wise before thou'st grow old'. I will recommend a book to you since that seems to be more accessable to you than the human interaction and experience sharing that we seek in this thread. Read "How to Lie with Statistics" and then you may view all your future company promotional links with a bit more skepticism. If you must reply with a personal attack do the forum a courtesy and email me privately and I can tell you what I really think about you.You have reordered the priorities several times already. . .I wonder why people thing design choices are so easy and cut and dried. Wishful thinking and a lack of willingness to do even the most basic research seems to be the order of the day.

Fred,

As a matter of fact I can tell you that I roll my own trafos for my DIY projects so I'm able to play with different parameters of the design as well as use different core materials and enjoy very much what I do.

On the other hand as I have said on other threads, in case you have not read them, I'm not an EE and lack a lot of basic knowledge on electronics. But I like to participate on these DIY discusions for two reasons, one to through my 2 cents and the other one is to learn from the collective experiance, even though my language barrier for which i have to do a special effort for posting, but that dosen't deter me from doing so since I have a lot of enthusiasm on what we discuss. And yes I might be wrong in many instances but that fortunately dosen't cause much harm.

I know you from other thread discusions so your tone to disagree does not boder me at all since I take you for what you are.

By the way how long is it since you last roll yourself a pair of tranies for your DIY project?

As a matter of fact I can tell you that I roll my own trafos for my DIY projects so I'm able to play with different parameters of the design as well as use different core materials and enjoy very much what I do.

On the other hand as I have said on other threads, in case you have not read them, I'm not an EE and lack a lot of basic knowledge on electronics. But I like to participate on these DIY discusions for two reasons, one to through my 2 cents and the other one is to learn from the collective experiance, even though my language barrier for which i have to do a special effort for posting, but that dosen't deter me from doing so since I have a lot of enthusiasm on what we discuss. And yes I might be wrong in many instances but that fortunately dosen't cause much harm.

I know you from other thread discusions so your tone to disagree does not boder me at all since I take you for what you are.

By the way how long is it since you last roll yourself a pair of tranies for your DIY project?

- Home

- Amplifiers

- Solid State

- What makes a good audio power transformer?